National standard for mediumspeed coal mill oil quality

Invited Review ArticleUnderstanding coal quality and the critical

2022年11月1日 Coal rank is defined by several parameters throughout the rank range, from heating value and moisture in lower rank coal (lignite and subbituminous), to volatile matter/fixed carbon and total carbon (proximate and ultimate analyses) in high and medium volatile 2017年8月1日 This model can be used to estimate the key parameters that are difficult to measure or cannot be measured: 1) coal powder or raw coal contents in coal mills, which can Modeling of a medium speed coal mill ScienceDirectASTM's coal and gas standards are instrumental in the testing and chemical analysis of coal, coke, natural gas and other gaseous fuels, as well as the combustion residues of coal and Coal Standards and Gas Standards Standards Products2020年5月8日 The Standardization Administration of China made the “Classification of Coalbody Structure” standard to categorize coal into original structural coal, tectonically crushed Research progress and prospects of coal petrology and coal

Coal Mill an overview ScienceDirect Topics

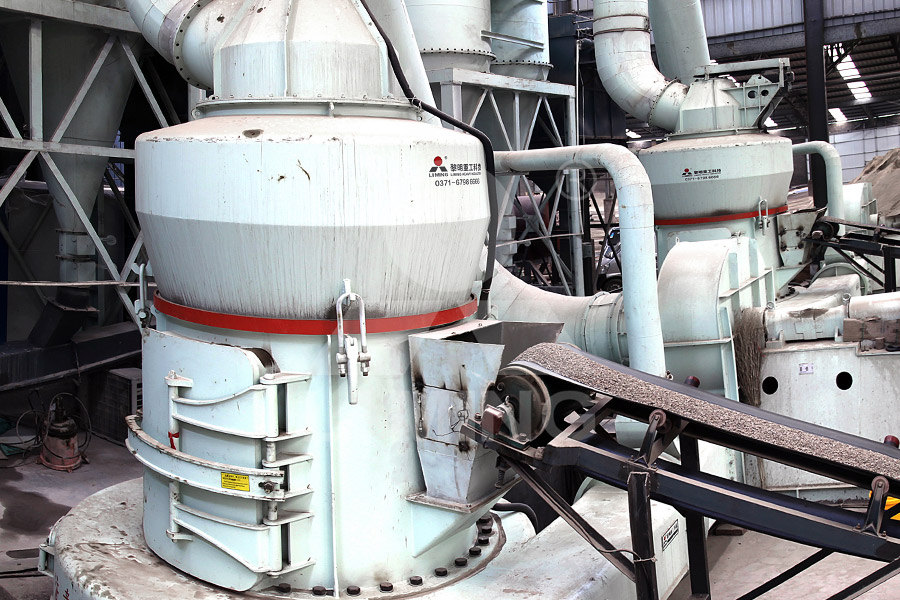

In such medium speed mills, the grinding bowl is rotated by a gearbox, while the grinding parts are pressed by external force either by springs or hydraulic cylinders against the grinding According to the characteristics of ZGM medium speed roller coal mill, such as wide adaptability of coal, high grinding efficiency, low power consumption, long service life, safety and reliability, ZGM type Mediumspeed Rolling coal millpower plant equipmentBased on the research results of predecessors and prediction studies of coal resources since the founding of China, the present status of research on coal petrology, coal quality, coal Research progress and prospects of coal petrology and coal Coal Bowl Mill, for guaranteed performance at a 500 MW capacity NTPC thermal power plant The study was conducted to assess the effective performance of the pulverizers of this 500 A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill Performance

Reliability centered early warning strategy for maintenance of

By selecting the key parameters characterizing the operation state of medium speed coal mill and field expert experience as the analysis basis, the digital maintenance early warning system of %PDF16 %âãÏÓ 651 0 obj >stream hÞì[ínܺ } >AL ‡ÀE€Û´÷"(Š q~ ‚‹41’ M $¾@úö=#ŽÖòÚFv%îÊLö‡ÑJ3ä ž QÔ ™Œ5Îx—Œ7!X L*Ñ$ã, SŒ£HÆ9ã‚ÇoÞ¸ìp Ù€‹É USEA United States Energy AssociationMPG medium speed coal mill is the product of upgrading MPS and MP medium speed coal mills In 1984, it cooperated with Germany Babcock Company for Liaoning Chaoyang Power Plant 2 × 200MW unit Augmentation Project provides 12 sets of MPS 212 medium speed coal mills, from which production and manufacture of MPS medium speed coal mills beganMPG Medium Speed Coal Mill NHIThe standard mill capacity for twenty (20) different mill sizes ranges from 10 tph to 190 tph (Figure 3) 4 Figure 2 First Generation MPS Mill with spring grinding force loading system Figure 3 MPS Mill standard capacity Loading frame Loading spring Guide frame Hot air inlet duct Motor Adjustable classifier vane Static classifier SLK COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS

.jpg)

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, HPSeriesMediumSpeedBowlMill 703 Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online HP Series Medium Speed Bowl Mill is used to grind, dry and separate raw coal into qualified fineness for combustion in steam boilers It consists of a grinding bowl, grinding rollers, spring loading device and other componentsHP Series Medium Speed Bowl Millmedium speed coal mill Dou Jie Shandong Huayu Institute of technology, Dezhou, Shandong, China : Abstract: HP type medium speed coal pulverizer produced by Shanghai heavy machinery works has been widely used in recent years, with common faults in operation, short maintenance cycle and heavy taskSHPHGLXPVSHHGFRDOPLOO IOPscienceThe standard mill capacity for twenty (20) different mill sizes ranges from 10 tph to 190 tph (Figure 3) o RPI MPS Mill Standard Capacity 200 180 160 140 120 100 80 60 40 20 100 112 125 140 150 160 170 180 190 200 212 225 235 245 255 265 280 290 300 315 Mill Size Figure 3, MPS Miff standard capacity,Coal Pulverizer Design Upgrades to Meet the Demands of Low

.jpg)

DRAFT PHILIPPINE NATIONAL STANDARD Virgin Coconut Oil for

DRAFT PHILIPPINE NATIONAL STANDARD PNS/PCA 202110/02 Virgin Coconut Oil for Human Consumption Committee Draft 1 1100 Scope 101 This standard applies to Virgin Coconut Oil (VCO) intended for human consumption 102 including use as Food Supplement 103 2 Normative Reference PNS/BAFPS 22:2007 ICS6720010 Virgin Coconut Oil104 105 3This document provides standard operating procedures for coal mill and coal feeder operations at a 1x525 MW thermal power plant in Tuticorin, Tamil Nadu, India It outlines responsibilities for personnel, safety and environmental procedures, work instructions, and references The purpose is to safely start and stop the coal mill and feeder while minimizing environmental impacts Key 15sop For Coal Mill and Feeder2018年12月14日 Microalgae cultivation using Palm Oil Mill Effluent (POME) as growth medium for biodiesel production in relation to light intensity and CO2 concentration December 2018(PDF) Microalgae cultivation using Palm Oil Mill ResearchGate2021年9月30日 This study strives in mapping of literature on the link between the palm oil business and environmental quality It selects a large amount of literature published in the Scopus Database from 2000 (PDF) Palm Oil Industries in Malaysia and Possible Treatment

Reliability centered early warning strategy for maintenance of medium

Abstract: In view of the frequent failure of coal mill due to the variable coal quality of power plant, the failure mode and influence of the system components of a medium speed coal mill in a power plant were analyzed by combining the multistate estimation algorithm, and a reliability oriented maintenance early warning strategy was proposed By selecting the key parameters Vertical MillMedium Speed MillBy May 2023, we have provided clients with 7700 sets of mill solutions We are a professional manufacturer of Vertical Mill (Medium Speed Mill)We always closely monitor global energysaving and Vertical MillMedium Speed MillTCU Technologies 1310 The power of motor for HP bowl mill is smaller than that of other medium speed pulverizers 1311 The ventilation resistance of HP coal mill is smaller than that of other medium speed pulverizers, and the air pressure of primary HP Bowl type millspower plant equipment2017年8月1日 Semantic Scholar extracted view of "Modeling of a medium speed coal mill" by Yaokui Gao et al Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 222,591,235 papers from all fields of Modeling of a medium speed coal mill Semantic Scholar

A Comparison of Three Types of Coal Pulverizers Babcock Power

The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in the mill and flat grinding surfaces, Standard Screen Typical Air to Coal Ratio at 100% Mill Load Specific Power @ 100% Mill Load 2017年8月1日 In this study, the lumped parameter modeling method is adopted with the following assumptions: 1) the parameters of the medium in the coal mill are uniform; 2) the media in the coal mill are incompressible; 3) the parameters of the medium in the coal mill change along the axial direction only; 4) the change in the flow power in the coal mill is ignored; 5) the coal Modeling of a medium speed coal mill ScienceDirect2017年12月15日 To realize rapid and effective evaluation and control on the performance of an MPS medium speed coal mill, a mathematical model was built up for the grinding, drying, separation and circulation Mechanism Modeling and Simulation for Coal Pulverizing System 2017年5月1日 As the significant ancillary equipment of coalfired power plants, coal mills are the key to ensuring the steady operation of boilers In this study, a fault diagnosis model was proposed on the Modeling of a medium speed coal mill ResearchGate

CrMo Alloy Steel Mill Liners For Coal Mill EB Castworld

EB specializes in production of Coal Mill Liner BTMCr15Mo for 20 yearsThe material includes ASTM A532,AS2027,BTMCr20Mo,BTMCr26Mo Chemistry Standard for CrMo Alloy Steel Mill Liners For Coal Mills: completed variety of quenching PHILIPPINE NATIONAL STANDARD PNS/BAFPS 22:2007 Virgin coconut oil (VCO) 1 Scope This standard applies to virgin coconut oil in a state for human consumption 2 References The titles of the standards publications referred to in this PNSBAFPS 222007VCO rev1 Department of Agriculture2020年4月7日 The mediumspeed coal mill system is mainly composed of ra w coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and c old air regulating valves The coal feeder Modeling of Coal Mill System Used for Fault 5 Oil skid purposely to the mill journal hydraulics systemAuxiliary steam supply for inerting circuit From the coal yard, the coal is transfer to the mill bunkers through conveyor belt The bunkers are sized for an effective capacity of twelve (12) hours at BMCR with design coal Each mill bunker has one hopper, connected to the feedersAnalysis of the Coal Milling Operations to the Boiler Parameters

MV VARIABLE SPEED DRIVE FOR COAL MILL CAPACITY IMPROVEMENT

In total, the low voltage solution of coal mill drive rated at 800 kW with step down transformer and new induction motor is priced somewhere between 2614 and 2949 kEuro It is obvious that for the case study power levels of coal mill drives, there is a clear advantage of MV variable speed inverter over LV solutionGenerally, the outlet temperature of the mediumspeed coal mill is controlled at 100 to 120 degrees Celsius The material processed by the mediumspeed mill barrel is particles of various sizes and hardnesses These materials move inside the mediumspeed mill, constantly causing friction, scouring and impact on various parts of the mediumspeed The cylinder of the mediumspeed coal mill is lined with wear defined nonlinear system and two actual fault cases of a mediumspeed coal mill Compared with the traditional methods, the experimental results demonstrate the effectiveness of the proposed methodA novel multimode Bayesian method for the processAs an important pulverized coal preparation equipment, medium speed mill has been facing the test of wear since its birth According to statistics, about 80% of the parts that fail in medium speed grinding belong to the direct or indirect consequences caused by metal wearMediumspeed coal mill wearresistant ceramic liner Composite

National Standard Coal Ball Mill Liners FMU 29 High Cr

High quality National Standard Coal Ball Mill Liners FMU 29 High Cr Martensitic Steel Casting from China, China's leading grinding mill liners product, with strict quality control ball mill liner replacement factories, producing high quality ball mill liner replacement productsKingcera Engineering Co,Ltd offers wear protective ceramics, abrasion resistant linings,wear resistant liners,ceramic lined pipes and bends,ceramic pulley lagging for various industriesWear resistant ceramic Ceramic wear liners Ceramic lined pipes A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics2018年3月15日 A grey box model was established for mediumspeed coal mill by combining the mechanism analysis method The method is implemented on IEEE standard 15 bus system with security and qualityFault Diagnosis of a Mediumspeed Coal Mill Based on

MPG Medium Speed Coal Mill NHI

MPG medium speed coal mill is the product of upgrading MPS and MP medium speed coal mills In 1984, it cooperated with Germany Babcock Company for Liaoning Chaoyang Power Plant 2 × 200MW unit Augmentation Project provides 12 sets of MPS 212 medium speed coal mills, from which production and manufacture of MPS medium speed coal mills beganThe standard mill capacity for twenty (20) different mill sizes ranges from 10 tph to 190 tph (Figure 3) 4 Figure 2 First Generation MPS Mill with spring grinding force loading system Figure 3 MPS Mill standard capacity Loading frame Loading spring Guide frame Hot air inlet duct Motor Adjustable classifier vane Static classifier SLK COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS 2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, Coal mill pulverizer in thermal power plants PPTHPSeriesMediumSpeedBowlMill 703 Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online HP Series Medium Speed Bowl Mill is used to grind, dry and separate raw coal into qualified fineness for combustion in steam boilers It consists of a grinding bowl, grinding rollers, spring loading device and other componentsHP Series Medium Speed Bowl Mill

.jpg)

SHPHGLXPVSHHGFRDOPLOO IOPscience

medium speed coal mill Dou Jie Shandong Huayu Institute of technology, Dezhou, Shandong, China : Abstract: HP type medium speed coal pulverizer produced by Shanghai heavy machinery works has been widely used in recent years, with common faults in operation, short maintenance cycle and heavy taskThe standard mill capacity for twenty (20) different mill sizes ranges from 10 tph to 190 tph (Figure 3) o RPI MPS Mill Standard Capacity 200 180 160 140 120 100 80 60 40 20 100 112 125 140 150 160 170 180 190 200 212 225 235 245 255 265 280 290 300 315 Mill Size Figure 3, MPS Miff standard capacity,Coal Pulverizer Design Upgrades to Meet the Demands of Low DRAFT PHILIPPINE NATIONAL STANDARD PNS/PCA 202110/02 Virgin Coconut Oil for Human Consumption Committee Draft 1 1100 Scope 101 This standard applies to Virgin Coconut Oil (VCO) intended for human consumption 102 including use as Food Supplement 103 2 Normative Reference PNS/BAFPS 22:2007 ICS6720010 Virgin Coconut Oil104 105 3DRAFT PHILIPPINE NATIONAL STANDARD Virgin Coconut Oil for This document provides standard operating procedures for coal mill and coal feeder operations at a 1x525 MW thermal power plant in Tuticorin, Tamil Nadu, India It outlines responsibilities for personnel, safety and environmental procedures, work instructions, and references The purpose is to safely start and stop the coal mill and feeder while minimizing environmental impacts Key 15sop For Coal Mill and Feeder

(PDF) Microalgae cultivation using Palm Oil Mill ResearchGate

2018年12月14日 Microalgae cultivation using Palm Oil Mill Effluent (POME) as growth medium for biodiesel production in relation to light intensity and CO2 concentration December 年9月30日 This study strives in mapping of literature on the link between the palm oil business and environmental quality It selects a large amount of literature published in the Scopus Database from 2000 (PDF) Palm Oil Industries in Malaysia and Possible Treatment