Wet coal ash processing fly ash equipment in power plants

.jpg)

Recovery, processing, and usage of wetstored fly ash

2017年1月1日 This chapter examines (i) the characteristics of wetstored fly ash, (ii) methods of sampling material, (iii) various wet processing techniques that can be used to remove or 2015年2月1日 Coal fly ash, a byproduct of coal combustion in thermal power plants, is one of the most complex and abundant of anthropogenic materials If not properly disposed of, it can A comprehensive review on the applications of coal fly ashFly ash is a fine powdery material produced by burning coal to generate electricity, primarily in pulverized coal combustion (PCC) boilers [1] Huge amounts of ash and related byproducts Fly Ash Separation Technology and its Potential ApplicationsCoal fly ash (CFA) is a coal ignition buildup at thermal power plants, which has been viewed as a hazardous waste globally The major problems with CFA are the large volume of land needed for its disposal and poisonous weighty metal Full article: A comprehensive review on coal fly ash and

.jpg)

Characterisation of Fly Ash from CoalFired Thermal

2016年10月28日 Previous study has shown that fly ash generated from the coalfired power station is a source of highly toxic metals like As, Cd, Pb, etc in addition to the metals that are crucial forIn this article, the authors provide an overview of fly ash, its chemical composition, the regulations from nations generating the greatest amount of fly ash, and epidemiological evidence A review on fly ash from coalfired power plants: chemical 2011年6月6日 Wet flue gas desulfurization, heterogeneous condensation, and chemical agglomeration have been reported to be promising methods for controlling fine particulate Wettability of Fly Ashes from Four CoalFired Power Plants in China2020年4月25日 Fly ash (FA) from lignite coal combusted in different Thermal Power Plants (TPPs) was used for the synthesis of zeolites (FAZs) of the NaX type by alkaline activation via three laboratory proceduresProgress in the Utilization of Coal Fly Ash by

.jpg)

Status of CoalBased Thermal Power Plants, Coal Fly

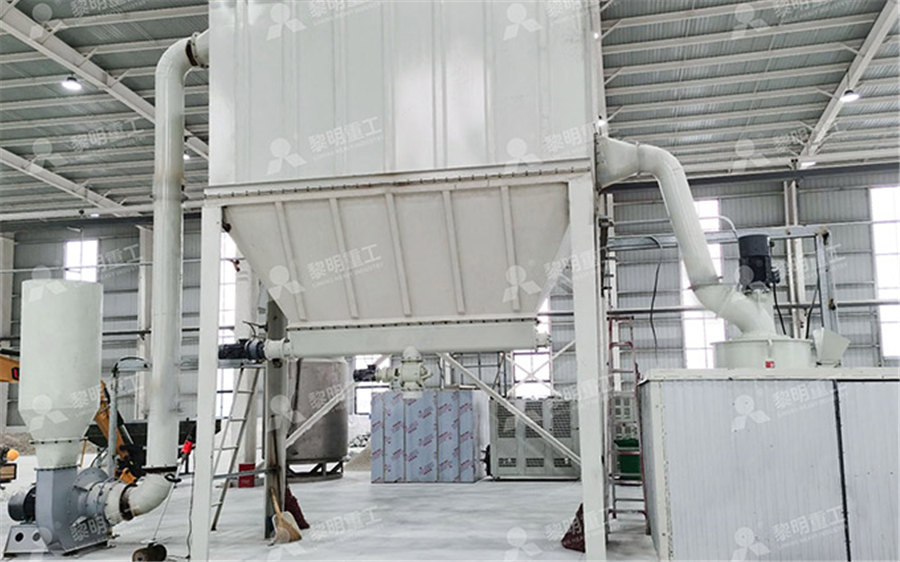

2022年11月25日 A detailed description of coal fly ashbased thermal power plants, fly ash production, and utilization is provided Moreover, the current and emerging applications of CFA are also provided Both fossil and renewable 2021年11月1日 Fly ash from coalfired power plants has become the world's largest solid waste pollutant The mechanochemical (MC) method used as a nonthermal method shows good stability to heavy metals in soil Mechanochemical stabilization of heavy metals in fly ash from coal Mechanical plant electrical services In Electrical Systems and Equipment (Third Edition), 1992 822 General description of ash handling plant The design of the ash handling plant is dependent upon the method of ash disposal It may be pumped into a disused quarry or transported from the power station for processing into building materialsAsh Handling Plant an overview ScienceDirect TopicsFly ash is generally a solid waste generated by the incineration boilers in thermal power plants, coalfired power plants, paper mills, and chemical factories, as well as the collection of ash from dust collectors It consists of tiny ash particles Fly Ash Processing Plant Ball Mill, Raymond Mill,

Status of CoalBased Thermal Power Plants, Coal Fly Ash MDPI

2022年11月25日 Both fossil and renewable fuel sources are used widely to produce electricity around the globe The dependency on fossil fuels for energy leads to the depletion of reserves and various forms of pollution Coal fly ash (CFA) is one of the most burning issues in the whole world due to its large amount of production in thermal power plants Every year a million tons 2022年10月26日 Coalpowered thermal plants are the primary source of energy production around the globe More than half (5689%) of the Indian power plants use coal for power production Coal burning in power plants results in coal combustion residuals, which contain coal fly ash (CFA) that is recognized as principle byproduct CFA is difficult to characterize due to The multiple value characteristics of fly ash from Indian coal 2011年6月25日 One of the major sources of Cr(VI) contamination is fly ash derived from coal combustion in thermal power plants (Gianoncelli et al, 2013; Mohanty and Patra, 2015; Verma et al, 2016)Fly ash from thermal power plants Waste management and overview2015年2月1日 Coal fly ash accounts for 5–20 wt% of feed coal and is typically found in the form of coarse bottom ash and fine fly ash, which represent 5–15 and 85–95 wt% of the total ash generated, respectivelyCoal ash is discharged by both wet and dry methods of coal combustion Bottom ash refers to the ash that falls down through the airflow to the bottom of the boiler and A comprehensive review on the applications of coal fly ash

Characterisation of Fly Ash from CoalFired Thermal Power Plants

PDF On Oct 28, 2016, MMALIK and others published Characterisation of Fly Ash from CoalFired Thermal Power Plants using Energy Dispersive XRay Fluorescence Spectrometry Find, read and cite Coalfired power plant fly ash is a global environmental concern due to its The SO 2 gas formed by the oxidation of sulfurcontaining substances is absorbed in a wet flue gas Rano R, Udaybhanu G, Basu A A comprehensive characterisation of fly ash from a thermal power plant in Eastern India Fuel Processing Technology 2006;87(3 FiringAssociated Recycling of CoalFired Power Plant Fly Ash2024年5月25日 Fly ash (FA) is a waste material from coal combustion in thermal power plants It is a potential candidate for CO 2 capture due to its high calcium oxide (CaO) content, which can undergo mineral carbonation There are various approaches for CO 2 capture using FA, including wet and dry scrubbing, carbonation, pressure swing adsorption, and membrane separationCO2 Capture Using Fly Ash SpringerLinkThe ash content of the coal used at the thermal power plants ranges from 3040%, with the average ash content around 38% Since low ash, high grade coal is reserved for metallurgical industries The thermal power plants have to use high ash, low grade coal The thermal power plants ash generation has increased from about 40 million tonnes duringCharacteristics of Fly Ash from Thermal Power Plants and its

Mechanochemical stabilization of heavy metals in fly ash from coal

2021年11月1日 With the massive increase in coal production, the fly ash from coalfired power plants has become the world's largest solid waste pollutant (Li et al, 2014)The longterm accumulation of fly ash will cause leakage of heavy metal elements (Stant, 2010)For China in 2015, the annual output of fly ash from coalfired power plants exceeded 580 million tons (Yao 2006年4月3日 An important observation is that the fly ash collected from Stokerfired thermal power plants possesses very poor distribution profile (AMD for as received fly ash ≥200 μm) View Show abstract(PDF) Prediction and Monitoring of Unburnt Carbon 2011年1月1日 127 Chemical Composition Chemical composition of fly ashes include silica (SiO 2), alumina (Al 2 O 3), and oxides of calcium (CaO), iron (Fe 2 O 3), magnesium (MgO), titanium (TiO 2), sulfur (SO 3), sodium (Na 2 O), and potassium (K 2 O), and unburned carbon (LOI) Amongst these SiO 2 and Al 2 O 3 together make up about 45–80% of the total ash Fly Ash SpringerLinkReuse options for coal fired power plant bottom ash and fly ash × high recovery and high purity products are only achievable through the processing of CFA using expensive and energy (2005) Castconcrete products made with FBC ash and wetcollected coalash J Mater Civ Eng 17:659 Nathan Y, Dvorachek M, Pelly I, Mimran U (1999 Reuse options for coal fired power plant bottom ash and fly ash

How Electrostatic Precipitators and Hopper Heaters Manage Fly Ash

2024年10月29日 Proper fly ash handling results in cleaner air, lower maintenance costs, increased plant safety, and an additional revenue stream Key Technologies for Effective Fly Ash Management in Power Plants Fly ash management is vital for power plants to meet environmental standards and maintain efficiency2012年2月1日 More than 100 million tons of fly ash is produced in the United States every year; most coming from the combustion of coal in power plants Nearly half of this fly ash is reused for purposes such Fly Ash Handling: Challenges and Solutions Power EngineeringThe Agency has defined economizer ash as bottom ash when “it is collected with the bottom ash” (40 CFR 42311f) and as fly ash when “it is collected with fly ash” (40 CFR 42311e)Coal Ash Management: Understanding Your Options Power 2014年4月1日 Reuse options for coal fly ash and coal bottom ash are reviewed in this paper Although, significant quantities of coal fly ash and coal bottom ash are produced worldwide every year, less than 30 % of coal ash produced is reused Coal ash is mainly reused in civil engineering applications such as road construction, embankments, construction materials, geo Reuse options for coal fired power plant bottom ash and fly ash

A review on fly ash from coalfired power plants: chemical

Throughout the world, coal is responsible for generating approximately 38% of power Coal ash, a waste product, generated from the combustion of coal, consists of fly ash, bottom ash, boiler slag, and flue gas desulfurization material Fly ash, which is the main component of coal ash, is composed of spherical particulate matter with diameters that range from 01 μm to gt;100 2024年4月18日 Coal ash, also referred to as coal combustion residuals or CCRs, is produced primarily from the burning of coal in coalfired power plants Coal ash includes a number of byproducts produced from burning coal, including: Fly ash, a very fine, powdery material composed mostly of silica made from the burning of finely ground coal in a boilerCoal Ash Basics US EPA US Environmental Protection Agency2018年9月30日 In thermal power plants, coal is used as a fuel for generating electricity Fly Ash – Around 80 % of ash generated in thermal power plant is fly ash Equipment’s Used in Ash Handling System in Thermal Power Plant Ash Handling System In Thermal Power Plant2018年11月2日 In addition to various pollutant gases, viz SO x and NO x, fly ash forms a major part of the exhaust gases from coalbased thermal power plants and if not managed properly may result in significant environmental pollution (He et al 2012)This is due to the presence of various heavy metals, eg, As, Ba, Cr, Se, Hg, etc, and adsorbed or deposited organic compounds Strategies for Collection, Treatment, and Recycling of Fly Ash from

.jpg)

Dry bottom ash handling system Magaldi

Due to growing concerns about water scarcity and evertightening environmental regulations, coalfired power plants are switching to dry ash handling technologies With 200+ dry bottom ash handling systems installed worldwide since 1985 for both new boilers and retrofits, Magaldi is uniquely placed in the dry ash handling field to demonstrate the benefits of its MAC ® system 2019年6月3日 Coalfired power plants represent the largest source of mercury emissions worldwide Using fly ash, a byproduct of these plants, as a sorbent to remove mercury has proven to be difficult Here, we found that the fresh surface of modified fly ash has good adsorption performance, and it declines obviously with time because of unsaturation characteristics on InSitu Capture of Mercury in CoalFired Power Plants Using High 2019年12月1日 Burning coal produces coal combustion residuals (CCR), or byproducts, which include fly ash, bottom ash, boiler slag, fluegas desulfurization residues, and fluidized bed combustion ash Over 70% of waste coal ash is categorized as fly ash (FA), fine particulates captured by particulate control equipment, ranging in size from 05 μm to 300 μm [ 3 , 4 ]Physical, chemical, and geotechnical properties of coal fly ash: 2023年8月16日 Harvested fly ash, an indispensable ingredient for contemporary cement manufacturing, is a fine, powdery byproduct of coal combustion originating from power plantsRich in silica, alumina, iron, and calcium, fly ash’s composition and properties are influenced by the type of coal used and the specificities of the combustion processFly ash processing: Tailored solutions for reclaimed fly ash Atritor

Coal Ash: Types, Effects and Solutions Cag

2020年10月10日 Figure 1: The coal flyash utilisation status of India’s coal power plants (Source: CEA, Annual Reports) The other types of coal ashes like bottom ash and boiler slag are collected into the ashpond, which is separately constructed into the marked territory of a coalfired power plant and is surrounded by an embankment2015年1月9日 Fly ash particles are the lightest kind of coal ash—so light that they “fly” up into the exhaust stacks of the power plant Filters within the stacks capture about 99 percent of the ash Coal Ash, Fly Ash, Bottom Ash, and Boiler Slag NRDC2018年1月1日 The concentration of critical elements, including such REE as Fe, Co, W, Zn, Cr, Ni, V, Mn, Ti, Ag, Ga, Ta, Sr, Li, and Cu, in the socalled fly ash obtained from the 9 Polish power plants and 1 Critical Elements in Fly Ash from the Combustion of Bituminous Coal in 2021年11月1日 Fly ash from coalfired power plants has become the world's largest solid waste pollutant The mechanochemical (MC) method used as a nonthermal method shows good stability to heavy metals in soil Mechanochemical stabilization of heavy metals in fly ash from coal

.jpg)

Ash Handling Plant an overview ScienceDirect Topics

Mechanical plant electrical services In Electrical Systems and Equipment (Third Edition), 1992 822 General description of ash handling plant The design of the ash handling plant is dependent upon the method of ash disposal It may be pumped into a disused quarry or transported from the power station for processing into building materialsFly ash is generally a solid waste generated by the incineration boilers in thermal power plants, coalfired power plants, paper mills, and chemical factories, as well as the collection of ash from dust collectors It consists of tiny ash particles Fly Ash Processing Plant Ball Mill, Raymond Mill,2022年11月25日 Both fossil and renewable fuel sources are used widely to produce electricity around the globe The dependency on fossil fuels for energy leads to the depletion of reserves and various forms of pollution Coal fly ash (CFA) is one of the most burning issues in the whole world due to its large amount of production in thermal power plants Every year a million tons Status of CoalBased Thermal Power Plants, Coal Fly Ash MDPI2022年10月26日 Coalpowered thermal plants are the primary source of energy production around the globe More than half (5689%) of the Indian power plants use coal for power production Coal burning in power plants results in coal combustion residuals, which contain coal fly ash (CFA) that is recognized as principle byproduct CFA is difficult to characterize due to The multiple value characteristics of fly ash from Indian coal

.jpg)

Fly ash from thermal power plants Waste management and overview

2011年6月25日 One of the major sources of Cr(VI) contamination is fly ash derived from coal combustion in thermal power plants (Gianoncelli et al, 2013; Mohanty and Patra, 2015; Verma et al, 2016)2015年2月1日 Coal fly ash accounts for 5–20 wt% of feed coal and is typically found in the form of coarse bottom ash and fine fly ash, which represent 5–15 and 85–95 wt% of the total ash generated, respectivelyCoal ash is discharged by both wet and dry methods of coal combustion Bottom ash refers to the ash that falls down through the airflow to the bottom of the boiler and A comprehensive review on the applications of coal fly ashPDF On Oct 28, 2016, MMALIK and others published Characterisation of Fly Ash from CoalFired Thermal Power Plants using Energy Dispersive XRay Fluorescence Spectrometry Find, read and cite Characterisation of Fly Ash from CoalFired Thermal Power Plants Coalfired power plant fly ash is a global environmental concern due to its The SO 2 gas formed by the oxidation of sulfurcontaining substances is absorbed in a wet flue gas Rano R, Udaybhanu G, Basu A A comprehensive characterisation of fly ash from a thermal power plant in Eastern India Fuel Processing Technology 2006;87(3 FiringAssociated Recycling of CoalFired Power Plant Fly Ash

.jpg)

CO2 Capture Using Fly Ash SpringerLink

2024年5月25日 Fly ash (FA) is a waste material from coal combustion in thermal power plants It is a potential candidate for CO 2 capture due to its high calcium oxide (CaO) content, which can undergo mineral carbonation There are various approaches for CO 2 capture using FA, including wet and dry scrubbing, carbonation, pressure swing adsorption, and membrane separation