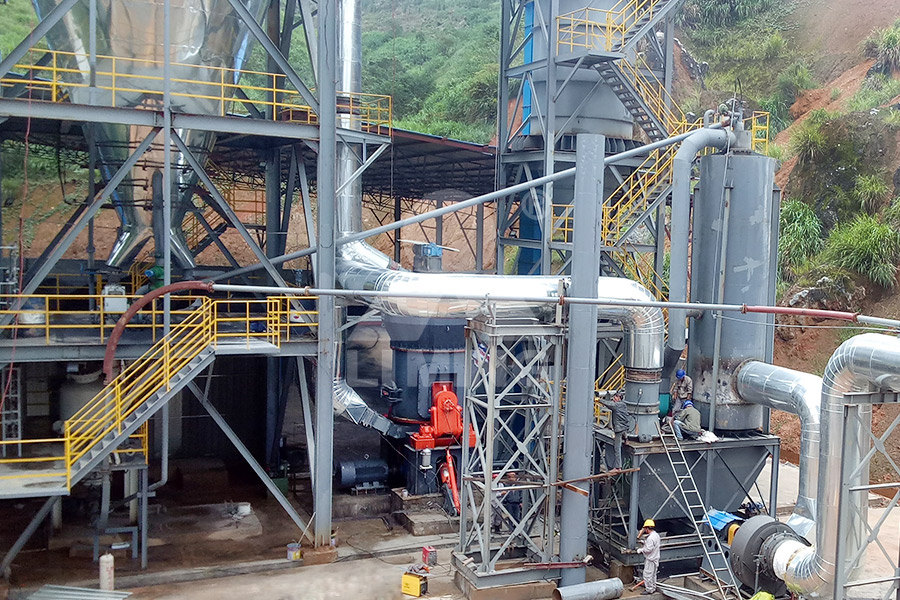

Anthracite lignite mill talc repair and maintenance

.jpg)

Reprint from ZKG 3 Gebr Pfeiffer

mill performance data between the different solid fuels such as anthracite, hard coal, lignite and pet coke Even within a single fuel type the deviation is quite high for grindability, ash The SOx emissions from lignite combustion are a function of the sulfur content of the lignite and the lignite composition (ie, sulfur content, heating value, and alkali concentration) The 17 Lignite Combustion US Environmental Protection AgencyThe MPS coal grinding mill with a high drying capacity is very suitable for grinding lignites with feed moistures of as much as 45 per cent Depending on this high feed moisture, the mill COAL GRINDING IMPS: more than meets the eye Gebr Pfeifferpulverised review of suitable technologies for the retrofitting of lignite coal power anti fouling the existing systems and steam turbine upgradesRetrofitting lignite plants to improve efficiency and performance

.jpg)

Mill Maintenance Methods ResearchGate

“Maintenance, repair and technical service are significant since they affect lifetime of milling machines and ensure them to work nonstop at desired levels If regular and goodspanning a continuous quality scale Coal is usually divided into four main categories: anthracite, bituminous, subbituminous and lignite/brown coal Lignite and subbituminous coals are Update on lignite firingAnthracite coal is a highrank coal with more fixed carbon and less volatile matter than either bituminous coal or lignite; anthracite coal also has higher ignition temperatures and ash fusion Background Document, AP42, Section 12, Anthracite Coal 2016年9月23日 It is imperative to improve the quality of lignite for largescale utilization To further explore and analyze the influence of various key processes on the environment and Future of lignite resources: a life cycle analysis

46.jpg)

Adding Metal Nitrates to Intensify Lignite and Anthracite

2023年8月27日 The influence of metal nitrates—KNO3, NaNO3, and Ca(NO3)2—as activating additives on the oxidation and combustion of lignite and anthracite is investigated The 2015年9月1日 Lignite milling differs fundamentally from milling bituminous and hard coals Adequate drying while avoiding mill fires during lignite milling are the main issues for Report on comparison among current industrial scale lignite The document discusses maintenance and repair of an ATOX Vertical Mill It describes systematic and conditionbased maintenance approaches Systematic maintenance consists of regular cleaning, lubrication and visual inspections Atox Vertical Roller Mill, Maintenance and Repair2018年6月8日 Properties of coal surface and pore structure are important aspects to be investigated in coal preparation and utilization In order to investigate the limits of different probe methods, a Surface Properties and Pore Structure of Anthracite,

.jpg)

Steel Mill Maintenance and Repair Services GMB Heavy Industries

Our steel mill maintenance and repair services consist of: Surveys/Inspection, Maintenance/Repair, Services for scheduled annual shutdowns Skip to content Address: 5165 Timberlea Blvd Mississauga, Ontario, L4W 2S3 Tel: +1 9052829395, +1 8772829724 REQUEST A QUOTE Home; About Us Mission Vision;2015年2月20日 The principal types of coal, in order of metamorphic development, are lignite, subbituminous, bituminous, and anthracite While not generally considered a coal, peat is the first development stage in the “coalification” process, in which there is a gradual increase in the carbon content of the fossil organic material and concomitant reduction in oxygenCoals, Lignite, and Peat Keppeler Wiley Online Library2023年8月27日 The influence of metal nitrates—KNO3, NaNO3, and Ca(NO3)2—as activating additives on the oxidation and combustion of lignite and anthracite is investigated The additives (5 wt %) are introduced in the samples by impregnation, according to the moisture capacity By thermal analysis and highspeed video recording of combustion, it is established that the Adding Metal Nitrates to Intensify Lignite and Anthracite 2022年7月1日 Atomic force microscopy results indicated that the anthracite–anthracite adhesion force is greater than that of lignite–lignite, and the adhesion force dominates particle interactions The surface electrostatic potential range of lignite (8557–8767 kcal/mol) is much higher than that of anthracite (6368–5960 kcal/mol) and the lignite surface provides more polar regions Insight into the selfaggregation behavior of lignite and anthracite

.jpg)

Ball Mill Maintenance Procedure: Tips for Maintaining Your Mill

A ball mill maintenance procedure is a crucial process in ensuring the longevity and efficient operation of your mill A poorly maintained ball mill can cause significant downtime, leading to costly repairs and lost production In this article, we will discuss the importance of regular maintenance, premaintenance steps, the ball mill maintenance procedure, postmaintenance 2024年10月11日 Scheduled maintenance: October 11, 2024 from 06:00 PM to 08:00 PM hello quizlet Study tools Subjects Create Log in anthracite this is the highest rank of coal bituminous this rank of coal looks shiny and smooth, but a closer look shows layers subbituminous this rank of coal looks dull lignite this coal is known as brown MNG 401 Flashcards Quizlet2015年1月1日 When the environment gradually becomes anoxic, anaerobic bacteria can ferment the celluloses to generate intermediate products such as CH 4, CO 2, C 3 H 7 COOH and CH 3 COOH These hydrolysis products and fermentation products may react with other plant decomposition products to form more complex substances and participate in coalificationGeological Characteristics of Coal SpringerLinkMaintenance and repair are performed when machine or equipment fails As a result, loss of production during repair is high Defects also can harm other machines or tools When performing corrective maintenance; the mill or its equipment is returned to base or original conditions and productivity by replacing parts or materials only after Cement Ball Mill Maintenance INFINITY FOR CEMENT EQUIPMENT

FYEFEPS2HDZ49G5Z0[B.jpg)

Surface Properties and Pore Structure of Anthracite,

2018年6月12日 Properties of coal surface and pore structure are important aspects to be investigated in coal preparation and utilization In order to investigate the limits of different probe methods, a comprehensive approach 2024年3月18日 This guide provides a comprehensive overview of the essential maintenance tasks and operational strategies for the Raymond Mill Routine Maintenance For Raymond Mill Daily Maintenance 1 Perform the following tasks every day when the mill is in operation: Cleaning: Use a broom and shovel to remove accumulated powder on the machine and Guide to Raymond Mill Maintenance: Schedule and Best Practices2023年10月31日 Batch experiments were conducted using lignite, coking coal, and anthracite as adsorbents Both coking coal and anthracite showed favorable adsorption properties for the chosen contaminants The experimental data Removal of Pyridine from Aqueous Solutions Using MRN pendulous hanging grinding mill represents the most advanced grinding processing technology at present, and its application of patent technology of brandnew structural design makes the equipment’s operation and maintenance cost much lower, environmental protection performance more excellent and discharging quality much superior, thus it is the optimum MRN Pendulous Hanging Grinding Mill Zenith Crusher

Mill maintenance – 3 simple ways to keep your mill at its best

2017年12月19日 This is where mill maintenance requires an intimate knowledge of the workings of your mill, through a planned care, inspection and monitoring programme The mill is one of the more complex pieces of process equipment and, as such, it will always pay to involve industry expertise in the inspecting, planning and execution of mill maintenance2021年3月12日 So far, the biggest mill for lignite coal grinding will be delivered to Cemindo’s Bayah plant in Indonesia This MPS 4500 BK has been ordered for grinding lignite with a maximum moisture of 37% and it is able to produce a throughput rate of minimum 100 t/h at a residue of 15% R009 mm The installed power for the mill main drive is 1300 kWMPS mills for coal grinding AYS Engineering2018年5月8日 "Maintenance, repair and technical service are significant since they affect lifetime of milling machines and ensure them to work nonstop at desired levels If regular and good maintenance is not performed, machines cannot work for long years Predictive maintenance monitors active machines and equipment in order to detect possible breakdownsMill Maintenance Methods Miller Magazinesteam/electric production Anthracite currently accounts for only a small fraction of the total quantity of coal combusted in the US The anthracite burned is primarily reclaim from old production as no new anthracite is mined Another form of anthracite coal burned in boilers is anthracite refuse, commonly known as culm12 Anthracite Coal Combustion US Environmental Protection

Hammer Mill Maintenance Pulva

2024年6月17日 Proper sizing and operation can help reduce maintenance costs and requirements, but maintenance is still required to maximize the efficiency of your hammer mill In our hammer mill maintenance guide, you will learn more about upkeep for these machines, including what regular and longterm maintenance tasks are required to keep your hammer These require regular inspections and maintenance We have a highly skilled team and equipment that is capable of executing repairs, inspections and maintenance on these Baseplate failure is a common problem when it comes to high powered equipment such as mills and scrubbers, this results from incorrect alignment and vibrationRepair Mill and Kiln Machines RobtekProactive maintenance delivers optimum grinding mill operation and efficiencies Planned regular maintenance shutdowns, reduces unscheduled mill downtime and improves performance Removal and change out of worn liners and lifters Mill Lining Removal and Maintenance Relines Maintenance is costeffective, the time and money spent on routine care, regular surveys and minor repairs protect the value of the building Good maintenance also helps to ensure the health and safety of building users and the general Maintenance and Repair of Older Buildings

Maintaining and Repairing Traditional Buildings

2018年9月17日 Maintenance and Repair Tips Use our guide to help manage the upkeep of your home in a costeffective way Maintenance Checklist The starting point for regular maintenance is to draw up a checklist to inspect your home in grinding lignite with feed moistures of as much as 45 % Depending on this high feed moisture the mill rating is determined by the drying process whereas for anthracite, hard coal and petcok e the rating of the mill is determined by the grinding process The great variety of solid fuel properties,Reprint from ZKG 3 Gebr PfeifferThere are four major types (or “ranks”) of coal Rank refers to steps in a slow, natural process called “coalification,” during which buried plant matter changes into an ever denser, drier, more carbonrich, and harder material The four ranks are:Anthracite: The highest rank of coal It is a hard, brittle, and black lustrous coal, often referred to as hard coal, containing a high What are the types of coal? US Geological Survey2016年10月20日 General Ball Mill Maintenance After the mill is erected, in order to avoid overlooking both obvious and obscure installation details, we recommend the use of a check list This is particularly recommended for multiple mill installations where it is difficult to control the different phases of installation for each and every millBall Mill Maintenance Installation Procedure 911Metallurgist

.jpg)

Types of Coal: What Are the 4 Main Types of Coal BKV Energy

Lignite The lowest rank of coal, containing 25% to 35% carbon It has the lowest energy content among coal types Lignite deposits are relatively young and were not subjected to extreme heat or pressure It is crumbly and has a high moisture content, which reduces its heating value Lignite accounted for 8% of total US coal production in 20212021年8月13日 Talc ultra fine powder grinding mill is an efficient industrial powder grinder machine It can grind 100+ kinds of ores into fine powder +17 [ protected] The free onsite onetoone operation, repair, maintenance, and other training Professional aftersales service team, 24 hours response to customer needsTalc Ultra Fine Powder Grinding Mill17 Lignite Combustion 171 General15 Coal is a complex combination of organic matter and inorganic ash formed over eons from successive layers of fallen vegetation Coals are classified by rank according to their progressive alteration in the natural metamorphosis from lignite to anthracite Coal rank depends on the volatile17 Lignite Combustion US Environmental Protection AgencyAnthracite is a highrank coal, representing a coal that has been subjected to the highest grade of metamorphism Anthracite is shiny black, hard and brittle (see Figure 28) and has the highest fixedcarbon content (approximately 86–98%)Due to its low volatile matter (2–12%), anthracite's combustion process is slow Most anthracites have lowmoisture content (about 3–6%) and Anthracite an overview ScienceDirect Topics

.jpg)

Atox Vertical Roller Mill, Maintenance and Repair

The document discusses maintenance and repair of an ATOX Vertical Mill It describes systematic and conditionbased maintenance approaches Systematic maintenance consists of regular cleaning, lubrication and visual inspections 2018年6月8日 Properties of coal surface and pore structure are important aspects to be investigated in coal preparation and utilization In order to investigate the limits of different probe methods, a Surface Properties and Pore Structure of Anthracite, Our steel mill maintenance and repair services consist of: Surveys/Inspection, Maintenance/Repair, Services for scheduled annual shutdowns Skip to content Address: 5165 Timberlea Blvd Mississauga, Ontario, L4W 2S3 Tel: +1 9052829395, +1 8772829724 REQUEST A QUOTE Home; About Us Mission Vision;Steel Mill Maintenance and Repair Services GMB Heavy Industries2015年2月20日 The principal types of coal, in order of metamorphic development, are lignite, subbituminous, bituminous, and anthracite While not generally considered a coal, peat is the first development stage in the “coalification” process, in which there is a gradual increase in the carbon content of the fossil organic material and concomitant reduction in oxygenCoals, Lignite, and Peat Keppeler Wiley Online Library

Adding Metal Nitrates to Intensify Lignite and Anthracite

2023年8月27日 The influence of metal nitrates—KNO3, NaNO3, and Ca(NO3)2—as activating additives on the oxidation and combustion of lignite and anthracite is investigated The additives (5 wt %) are introduced in the samples by impregnation, according to the moisture capacity By thermal analysis and highspeed video recording of combustion, it is established that the 2022年7月1日 Atomic force microscopy results indicated that the anthracite–anthracite adhesion force is greater than that of lignite–lignite, and the adhesion force dominates particle interactions The surface electrostatic potential range of lignite (8557–8767 kcal/mol) is much higher than that of anthracite (6368–5960 kcal/mol) and the lignite surface provides more polar regions Insight into the selfaggregation behavior of lignite and anthracite A ball mill maintenance procedure is a crucial process in ensuring the longevity and efficient operation of your mill A poorly maintained ball mill can cause significant downtime, leading to costly repairs and lost production In this article, we will discuss the importance of regular maintenance, premaintenance steps, the ball mill maintenance procedure, postmaintenance Ball Mill Maintenance Procedure: Tips for Maintaining Your Mill2024年10月11日 Scheduled maintenance: October 11, 2024 from 06:00 PM to 08:00 PM hello quizlet Study tools Subjects Create Log in anthracite this is the highest rank of coal bituminous this rank of coal looks shiny and smooth, but a closer look shows layers subbituminous this rank of coal looks dull lignite this coal is known as brown MNG 401 Flashcards Quizlet

Geological Characteristics of Coal SpringerLink

2015年1月1日 When the environment gradually becomes anoxic, anaerobic bacteria can ferment the celluloses to generate intermediate products such as CH 4, CO 2, C 3 H 7 COOH and CH 3 COOH These hydrolysis products and fermentation products may react with other plant decomposition products to form more complex substances and participate in coalificationMaintenance and repair are performed when machine or equipment fails As a result, loss of production during repair is high Defects also can harm other machines or tools When performing corrective maintenance; the mill or its equipment is returned to base or original conditions and productivity by replacing parts or materials only after Cement Ball Mill Maintenance INFINITY FOR CEMENT EQUIPMENT