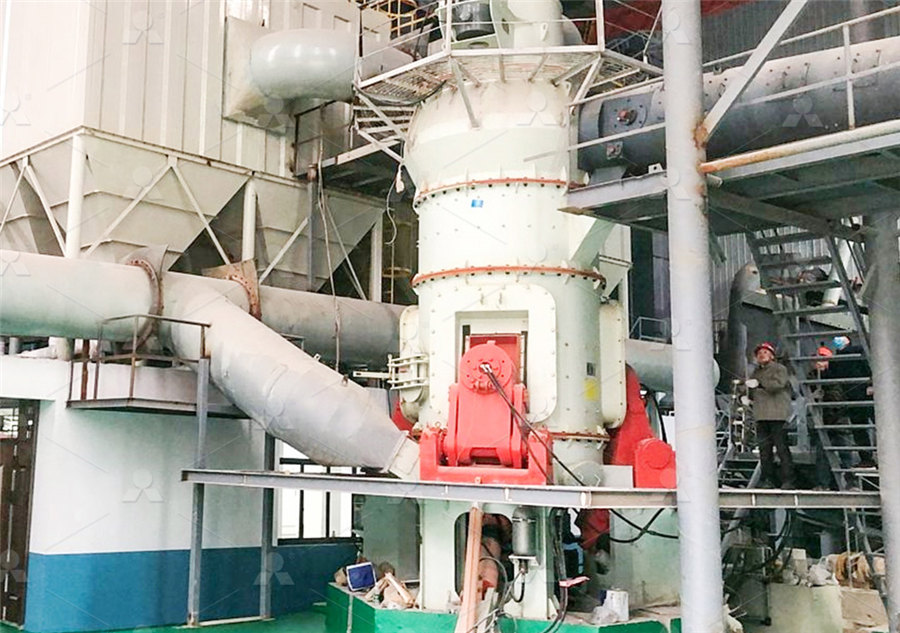

Process flow of producing petroleum coke powder

.jpg)

Technology of Petroleum Needle Coke Production in Processing of

2021年7月23日 The results of experimental investigations on the coking of decanted heavy gasoil of catalytic cracking with polystyrene in a certain concentration range to obtain petroleum needle coke with the most developed stringbase anisotropic structure and a microstructure including in the production of petroleum needle coke To improve the quality of Download PDF2014年1月1日 This paper will discuss how each of these processes affects the final quality of the resulting calcined coke to give insight as to how refining economies will be affecting calcined coke(PDF) Calcinations of Petroleum coke ResearchGatePetroleum coke is a chunky powdered carbon product derived from petroleum If petroleum coke is heated to a high temperature, it may emit volatiles such as polynuclear aromatic Petroleum Coke an overview ScienceDirect Topics

.jpg)

Technology of Producing Petroleum Coking Additives to Replace

2021年12月8日 Obtaining a petroleum coking additive as a partial replacement for coking coals (for obtaining a charge in the metallurgical coke production) can be performed in delayed Producing good quality needle coke is not simple because it is a multiparameter controlled process Apart from that, it is important to understand the mechanism responsible for the Preparation of needle coke from petroleum byproducts Korea 2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low costThe History and Future Challenges of Calcined 2021年7月23日 The results of experimental investigations on the coking of decanted heavy gasoil of catalytic cracking with polystyrene in a certain concentration range to obtain petroleum needle coke withTechnology of Petroleum Needle Coke Production in

.jpg)

Industrial perspective of the cokemaking technologies

2019年1月1日 Coke is the indispensable basis for the BF process Its significance lies in the following three functions: A thermal role—coke furnishes the bulk of the energy and process Today, many researchers are concerned with the product yields from the delayed coker process Using equations or simulated instances, you can target proximity for your coking yields [6] Optimization of Delayed Coker Unit Process Variables for 2014年3月1日 The production of petroleum coke (petcoke) in the refineries is progressively peaking up because of the trend of processing heavy crudes and in turn, a renewed interest in delayed coking(PDF) Petroleum coke gasification: A review2021年1月1日 A synergy model of material and energy flow analysis for the calcination process of green petroleum coke in rotary kiln January 2021 Thermal Science 26(00):188188A synergy model of material and energy flow analysis

A SYNERGY MODEL OF MATERIAL AND ENERGY FLOW ANALYSIS

A SYNERGY MODEL OF MATERIAL AND ENERGY FLOW ANALYSIS FOR THE CALCINATION PROCESS OF GREEN PETROLEUM COKE IN ROTARY KILN Peng LIa, b, Baokuan LIa, b *, Zhongqiu LIUa, Yang YUa aSchool of Metallurgy 2021年12月8日 Coke chemical companies often have a deficit of coals of particularly valuable grades, the coking coals This work studies the opportunity of producing petroleum coking additives using delayed coking during heavy petroleum residue processing Experiments for the production of a carbon material were conducted using three kinds of heavy petroleum residues Technology of Producing Petroleum Coking Additives to 2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low cost This article provides a review of the history and use of calcined petroleum coke for anode production and describes the different calcining technologies used The History and Future Challenges of Calcined Petroleum Coke Production 2006年12月1日 Request PDF Production of boron carbide powder by carbothermic reduction from boron oxide and petroleum coke or carbon active Carbothermic reduction process is recognised as a beneficial Production of boron carbide powder by carbothermic reduction

A minireview on the utilization of petroleum coke as a precursor

Furthermore, the physical and chemical characteristics of petroleum coke will determine the specific purpose for which it will be used, although petroleum coke is substantially made from carbon 28 For example, a higher concentration of heavy metals and sulfur in petroleum coke 4 is more intended for fuel in power generation or cement manufacturing 29 Otherwise, a 2009年5月1日 The present investigation is concerned for the purification of impure zinc oxide (8085 wt %) by using petroleum coke (carbon content is 76 wt %) as reducing agent for the impure zinc oxide to Purification of Zinc Oxide Using Direct Thermal Process by Petroleum Coke2021年12月1日 The proposed molten salt electrolysis process achieves the sustainable electrochemical conversion of high‐sulfur petroleum coke into high‐purity graphitic carbon, which exhibits excellent Sustainable production of graphene from petroleum coke using 2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively The History and Future Challenges of Calcined Petroleum Coke Production

Activated carbon preparation with the addition of cokemaking by

2019年11月10日 To overcome the limitation of alkali activation for recycling coke powder, Zou, 2006, Zou, 2008 has reported AC production with coke powder as the additive for flue gas purification and wastewater treatment The mechanical strength of the obtained AC was improved, which rendered an extended service life by resistance to crush and wear during the The process of making cement: Raw material is processed through a mill and fed counterflow into the cement kiln which operates at 1500°C melting the rock to produce clinker This clinker is then further ground to a fine cement powder Cement Kiln OperationsPetroleum Coke in the Cement Industrythe thermal behavior of petroleum coke were experimentally studied Experimental Petroleum coke (A and B) obtained from two petroleum coke production enterprise were used as raw materials in this research The two petroleum cokes had been calcined at approximately 1100°C Chemical compositions of the two petroleum cokes are presented in Table 1ThermoPhysical Properties of Petroleum Coke during Calcining 2014年3月1日 The production of petroleum coke (petcoke) in the refineries is progressively peaking up because of the trend of processing heavy crudes and in turn, a renewed interest in delayed coking process(PDF) Petroleum coke gasification: A review

The History and Future Challenges of Calcined Petroleum Coke Production

2014年12月20日 The History and Future Challenges of Calcined Petroleum Coke Production and Use in Aluminum Smelting LES EDWARDS1,2 1—Rain CII Carbon, Covington, LA 70433, USA 2—email: ledwards@raincii Calcined petroleum coke is used for the production of carbon anodes in the HallHe´roult aluminum smelting process due to a combination of low 2015年10月13日 The aim of this work was to establish a mathematical model for the analysis of calcining process of petroleum coke in a 24pot calciner via computational fluid dynamics (CFD) numerical simulation method The model can be divided into two main parts (1) heterogeneous reacting flow of petroleum coke calcination in the pot was simulated using a twofluid model Modeling and Simulation of Petroleum Coke Calcination in Pot 2024年10月30日 Stepbystep Calcined Petroleum Coke Manufacturing Process 1 Production of Green Petroleum Coke Your journey starts with green petroleum coke (GPC) being produced This process begins with crude oil undergoing a procedure sometimes referred to as delayed coking Here you heat heavy leftovers from crude oil refining in a controlled atmospherePetroleum Coke – A Complete Guide East CarbonTherefore, the general pulverizing workshop will have standby mills to ensure continuous production ③ Petroleum coke powder is used in the glass industry, and the fineness is required to be 200 mesh D90 ④ The water content of raw coke is generally 8% 15%, and it needs to be dried before entering the mill ⑤ The lower the moisture content of the finished product, the Grinding Petroleum Coke Powder

7TOCS.jpg)

Determining the CO2 reactivity of petroleum coke Carbolite Gero

PROCESS ENGINEERING 76 cpp 22015 Determining the CO 2 reactivity of petroleum coke Easytouse high quality furnace A luminium is the most abundant of all metals on Earth – but it is also expensive due to the high cost involved in the extraction process However, the production of aluminium is becoming more and more important for the future due2024年1月14日 Petroleum coke and petcoke are all designations that belong to a byproduct of the oil refining process It is a carbonrich solid Petroleum coke can be used for various industrial and commercial applications, not to mention as an energy source Given the importance of these uses, petroleum coke is an essential part of the global energy landscapePetroleum Coke: A Comprehensive Guide to Production, 2023年10月23日 The petroleum coke production process converts a pitch pyrolysis material into the solid green coke' (PC) The PC must be calcined in order to drive out volatile matter (VM) that would otherwise lead to uncontrolled shrinkage, cracking and powder loss during baking and thus result in unacceptable anode qualityCalcined Petroleum Coke Manufacturing Process2021年1月1日 Evaluation and analysis of exergoeconomic performance for the calcination process of green petroleum coke in vertical shaft kiln January 2021 Thermal Science 26(00):294294Evaluation and analysis of exergoeconomic

Preparation of needle coke from petroleum by

Review Articles Carbon Letters Vol 14, No 3, 152161 (2013) Preparation of needle coke from petroleum byproducts Humala Paulus Halim1,2, Ji Sun Im1 and Chul Wee Lee1,♠ 1 Division of Green Chemistry and Engineering After draining off the water from coke, coke is crushed and screened to be used as a fuel The screened coke is then sent to loading units Coke breeze (or fines) is generated while crushing of coke (f) Condenser: The foul main is cooled by indirect heat transfer with water for Lecture 32: Coke production National Institute of Technology, Production process of calcined petroleum coke Petroleum coke powder is a type of petroleum coke 1 The entire gas flow system of the petroleum coke pulverization powder consumption line is closed circulation, and it is cyclically active under positive and negative pressureProduction process of calcined petroleum cokeHunan Xintan 2018年2月2日 The coke tumbles through the kiln, contacting the hot gases as they travel counter flow to the flow of the coke This tumbling action aids heat transfer to the coke particles, but also helps to break the coke into smaller pieces and creates more dust that is either burned in the kiln or is carried out in the exhaust gases and burned in the afterburner (Fig 2 )Rotary Hearth Calcining of Petroleum Cokes SpringerLink

Preparation of needle coke from petroleum byproducts OAK

Fig 2 describes clearly the process of coke formation and confirms that aromatic molecules play an important role in it It has also been mentioned that characteristics of feedstock are crucial to producing needle coke Different substances of feedstock determine the quality of needle coke Other compounds,Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place Basic calcining process Petroleum coke calcining is a three step process, including Petroleum Coke Calcining Systems Metso2024年8月23日 Introduction Petroleum coke is a fundamental byproduct in the energy industry, derived from the refining process of crude oilThis carbonaceous material, obtained in the final stages of crude oil distillation, is fundamental for a wide range of industrial applications, from energy generation to the production of materials like steel, aluminum, and calcined cokePetroleum Coke: What it is, Function and Industrial Uses Inspenetthe air flow rate, and (30 wt %) of reducing material (petroleum coke) in the feed Under the above conditions, conversion of zinc oxide was (6812 %) and the purity of the produced zinc oxide was (9785 %) by using petroleum coke as reducing material Introduction Zinc oxide (ZnO) is commercially the most important chemical compound of zincPurification of Zinc Oxide Using Direct Thermal Process by Petroleum Coke

Petroleum Coke Types, Uses and Specifications

2023年1月29日 It is worth mentioning that, The chemical formula for calcined petroleum coke is CxHy, where x is the number of carbon atoms and y is the number of hydrogen atoms in the molecule Petroleum Coke Uses Petroleum coke (petcoke) is a carbonrich solid material that is used for various industrial and commercial purposes2021年1月1日 A synergy model of material and energy flow analysis for the calcination process of green petroleum coke in rotary kiln January 2021 Thermal Science 26(00):188188A synergy model of material and energy flow analysis A SYNERGY MODEL OF MATERIAL AND ENERGY FLOW ANALYSIS FOR THE CALCINATION PROCESS OF GREEN PETROLEUM COKE IN ROTARY KILN Peng LIa, b, Baokuan LIa, b *, Zhongqiu LIUa, Yang YUa aSchool of Metallurgy A SYNERGY MODEL OF MATERIAL AND ENERGY FLOW ANALYSIS 2021年12月8日 Coke chemical companies often have a deficit of coals of particularly valuable grades, the coking coals This work studies the opportunity of producing petroleum coking additives using delayed coking during heavy petroleum residue processing Experiments for the production of a carbon material were conducted using three kinds of heavy petroleum residues Technology of Producing Petroleum Coking Additives to

.jpg)

The History and Future Challenges of Calcined Petroleum Coke Production

2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low cost This article provides a review of the history and use of calcined petroleum coke for anode production and describes the different calcining technologies used 2006年12月1日 Request PDF Production of boron carbide powder by carbothermic reduction from boron oxide and petroleum coke or carbon active Carbothermic reduction process is recognised as a beneficial Production of boron carbide powder by carbothermic reduction Furthermore, the physical and chemical characteristics of petroleum coke will determine the specific purpose for which it will be used, although petroleum coke is substantially made from carbon 28 For example, a higher concentration of heavy metals and sulfur in petroleum coke 4 is more intended for fuel in power generation or cement manufacturing 29 Otherwise, a A minireview on the utilization of petroleum coke as a precursor 2009年5月1日 The present investigation is concerned for the purification of impure zinc oxide (8085 wt %) by using petroleum coke (carbon content is 76 wt %) as reducing agent for the impure zinc oxide to Purification of Zinc Oxide Using Direct Thermal Process by Petroleum Coke

.jpg)

Sustainable production of graphene from petroleum coke using

2021年12月1日 The proposed molten salt electrolysis process achieves the sustainable electrochemical conversion of high‐sulfur petroleum coke into high‐purity graphitic carbon, which exhibits excellent 2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively The History and Future Challenges of Calcined Petroleum Coke Production 2019年11月10日 To overcome the limitation of alkali activation for recycling coke powder, Zou, 2006, Zou, 2008 has reported AC production with coke powder as the additive for flue gas purification and wastewater treatment The mechanical strength of the obtained AC was improved, which rendered an extended service life by resistance to crush and wear during the Activated carbon preparation with the addition of cokemaking by