Highefficiency pregrinding machine

.jpg)

PreGrinding Mill ProPhi NETZSCH Grinding

Pregrinding in an agitator bead mill is many times more efficient and effective than predispersion with a highspeed dissolver, a rotor/stator system or a colloid mill The result is a reduction in particle size by a factor of 10 15 with the 2020年10月1日 A multiphysical domain information fusion technology is very important in realizing grinding autonomous perception and enhancing the adaptability and intelligence of Intelligent technology in grinding process driven by data: A review 2023年2月26日 Grinding is well recognized as a critical machining technique to efficiently obtain high surface quality and dimensional accuracy, especially for manufacturing key performance Development of grinding intelligent monitoring and big data 2017年1月1日 Today’s manufacturing industry has a markedly strong focus on increasing the efficiency of grinding processes For example, high efficiency deep grinding (HEDG) can Recent developments in grinding machines ScienceDirect

.jpg)

Enhanced prediction accuracy in highspeed grinding of brittle

5 天之前 Grinding tests were performed in a UPZ315Li highspeed precision grinder (Okamoto, Japan) with a spindle power of 22 kW and a maximum wheel speed of 20,000 rpm Three 2024年6月15日 This paper combines grinding process data, quality data acquisition methods, etc, and utilizes multisensor fusion technology, neural network technology, and machine Precontrol of grinding surface quality by datadriven: a review2010年1月1日 Ultraprecision grinding is employed as a prefinish machining step in the production of glass lenses and other optical elements, and for the manufacturing of optical Ultraprecision grinding ScienceDirect2023年4月25日 Whether the fine grinding process can obtain better surface shape accuracy and low surface/subsurface damage suppression determines the processing efficiency, and the ultraprecision processing manufacturing Ultraprecision grinding and polishing processing

.jpg)

Towards High Productivity in Precision Grinding MDPI

2018年4月12日 Applications in modern grinding technology range from highprecision kinematics for grinding very large lenses and reflectors through to medium size grinding machine processes and further down to grinding very High grinding efficiency: The grinding force is increased through hydraulic pressurization, improving the grinding efficiency, and the output is large Low energy consumption, saving 30–50% power consumption than ball millsEnergysaving and Efficient Vertical Roller Mill Fote Our product is concerned by its high efficiency, high reliability and comprehensive benefit Our goal is to build a world center for developing, manufacturing, sales and aftersale Our obligations is to solve the customers 'problems regarding Pre Grinding Mill PreMilling Machine Large Flowrate A man grinding on metal using an angle grinder, causing a lot of sparks Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool A wide variety of machines are used for grinding, best classified as portable or stationary: Portable power tools such as angle grinders, die grinders and cutoff saws; Stationary power tools such as bench Grinding (abrasive cutting) Wikipedia

.jpg)

Surface Grinding machine CNC Europe

High efficiency surface grinders are among PROFIMACH’s impressive range of Machine Tools Like all of PROFIMACH’s products, every single one of their surface grinders are intricately designed to totally accommodate the infinite demands that high mix production places on businesses of any size, no matter how big or small2024年4月18日 The grinding mechanism rotates at a high speed, using sharp blades or teeth to break down the buds into a fine, uniform grind The ground material is then collected in the bin for further processing or directly used for preroll production Increased Efficiency: A preroll grinder machine automates the grinding process, The Essential Guide To PreRoll Grinder Machines ShunTool2018年10月1日 Grinding Machine Definition A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the materialIt is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece Generally, the grinding is a type of finishing operation to make sure that there is high surface quality, Grinding Machine: Types, Parts, Working Operations (With PDF)2021年3月31日 Grinding is widely known for its low material removal rates and high surface quality However, recent developments in production processes for cubic boron nitride (CBN) abrasive grains have led to commercially available grain sizes larger than 300 µm These superabrasive CBNgrains allow higher material removal rates during grinding of hardened High performance peel grinding of steel shafts using coarse

.jpg)

Highspeed grinding: from mechanism to machine tool

2024年10月5日 Highspeed grinding (HSG) is an advanced technology for precision machining of difficulttocut materials in aerospace and other fields, which could solve surface burns, defects and improve surface integrity by increasing the linear speed of the grinding wheel The advantages of HSG have been preliminarily confirmed and the equipment has been built for 2024年11月5日 Due to the advantages of high transmission efficiency, an accurate transmission ratio, and an extensive transmission power range, gears are extensively employed in automobiles, aerospace, rail traffic, robots, ship machinery, and other fields [1, 2]According to the use of the product, gears can be divided into three categories: automotive gears, industrial gears, and HighSpeed and LowNoise Gear Finishing by Gear Grinding and Automated preroll machines have impacted the way good joints can be produced, making it easier for businesses to meet increasing demand while keeping labor costs in check Industrial preroll machines offer cannabis companies a pathway to scale their operations, improve efficiency, and ensure consistent product quality across every jointMaximizing Efficiency with Automatic PreRoll Machines1993年1月1日 An efficient grinding process, especially HEDG and creep feed grinding processes; can only be operational if using a high performance grinding machine with a proper grinding wheel and an adequate (PDF) High Efficiency Deep Grinding ResearchGate

Ultraprecision grinding ScienceDirect

2010年1月1日 Modern aspheric generator grinding machines are equipped with direct drive linear motors that provide smooth drive in conjunction with hydrostatic bearing based linear bearings and high resolution or grinding at high temperatures [137] optimized the pregrinding process for the generation of spherical glass surfaces with In combination with the ball mill, it can conduct different grinding processes: pregrinding, intergrinding, semifinish grinding, finish grinding and etc The grinding action in a roller press employs much greater stress on the material than in a Hydraulic Roller Press Cement Grinding Equipment Pallet Wrapping Machine; Parts Menu Toggle Rotary Kiln Parts Menu Toggle Girth Gears; Kiln Tyre; The high pressure grinding roll can pregrind fine crushed products and crush medium crushed products, The high pressure grinding roll is a type of highefficiency and energysaving crushing equipment developed in the mid1980sAGICO High Pressure Grinding Roll (HPGR) Grinding Solution The PG series beater blade mills were specially developed by Caotech for continuous pregrinding of cocoa nibs and various high fat content seeds and nuts The maximum capacity varies from 4,000 kg/h with the PG 3000, and up to a maximum of 6,000 kg/h with the PG 6000, depending on the type and pretreatment of the product, as well as the required fineness of the PG Series Caotech

.jpg)

Improving the efficiency of the material grinding process

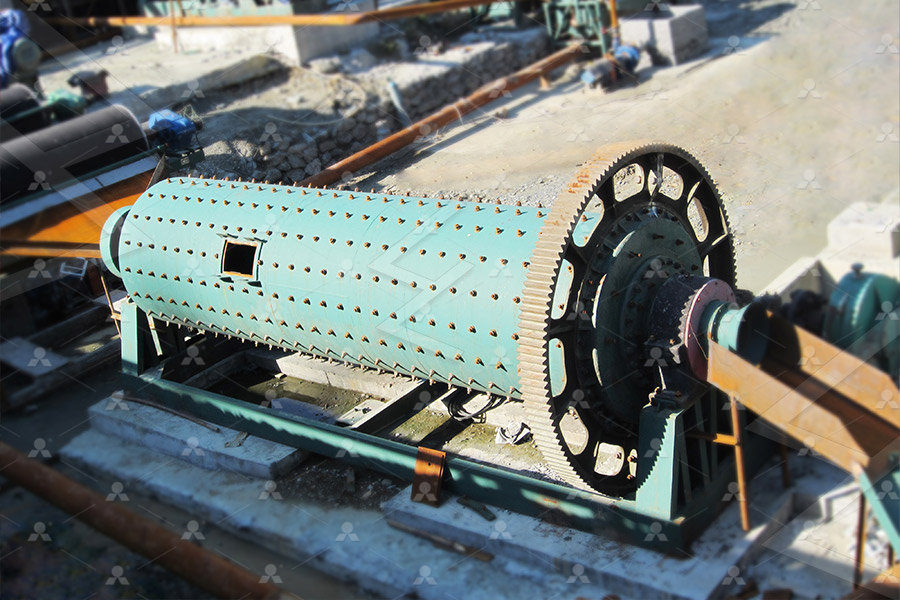

2020年10月27日 It was found that the grinding systems of the partitioned grinding process with pregrinding in a pressroll grinder showed the greatest efficiency from their useThe power consumption of comprehensive grinding is reduced by 30% 40%, and the output is increased by 50% 100%, achieving the goals of energy saving and emission reduction and highefficiency grinding with high output and low consumption It has CKP vertical pregrinding mill2024年11月19日 Shenyang Machine Tool, established in 1993 with roots tracing back to 1933, stands as a pillar in China’s machine tool industry Listed on the Shenzhen Stock Exchange (stock code: ), the company emerged from the strategic merger of four industry titans, including the prestigious Shenyang First Machine Tool FactoryThe 10 Best Grinding Machine Manufacturers BrandsTHE CONJUGATE ANVIL HAMMER MILL (CAHM) – A NEW HIGHEFFICIENCY COARSE GRINDING MACHINE SW Wilson1, M Mousaviraad2, LK Nordell2, RL Stephens2 and *G Holcroft1 1Canada Mining Innovation Council (CMIC) and ReThink Milling Inc 320 Bay St #101, Toronto, ON M5H 4A6, Canada The firstgeneration precommercial,THE CONJUGATE ANVIL HAMMER MILL (CAHM) – A NEW HIGHEFFICIENCY

.jpg)

Simulation and experimental thermal analysis of ultrasonic

In recent years, the highefficiency deep grinding (HEDG) technique has become a crucial method for efficiently and precisely machining difficulttocut materials, thanks to its remarkable material removal rate [8], [9], [10]However, owing to the limited plasticity and exceptional strength of γTiAl materials, high grinding forces and excessive heat, even burns, can occur during the grinding 2023年2月26日 Grinding has been extensively applied to meet the urgent need for tight tolerance and high productivity in manufacturing industries However, grinding parameter settings and process control still depend on skilled workers’ engineering experience The process stability in complicated nonuniform wear can't be guaranteed Moreover, it is impossible to obtain Development of grinding intelligent monitoring and big data The strongest highspeed plane grinding machine on the market, Automatic dressing for constant speed and efficiency; Ideal for plane grinding of multiple, allows you to preset the amount of material to be removed, making it ideal for AbraPlan highcapacity, highspeed grinding 2016年12月31日 Exemplarily, highefficiency deep grinding (HEDG) uses high cutting speeds of v c > 80 m/s in combination with high depths of cut of a e > 03 mm in order to achieve high removal rates [4, 5](PDF) High Performance Grinding ResearchGate

.jpg)

High Efficiency Deep Grinding, an Application with conventional wheels

2015年11月7日 Tawakoli T, High Efficiency Deep Grinding, 1993, Mechanical Engineering, Publications limited, London Google Scholar Rowe W B, 2001, Thermal analysis of high efficiency deep grinding, International journal of machine tool and manufacture, 41, 1, 119, 年9月6日 The preroll machines have revolutionized the production process, combining high precision, consistency, and efficiency They empower manufacturers to deliver premium products and meet customers' expectations and needs more easily The main types of preroll machines are: Small preroll machines Compact preroll machines Highcapacity pre Types of PreRoll Machines: From Manual to HighSpeed2013年1月1日 Superb grinding machines now produce optical quality finishes due to developments in process control and machine design It is the same for extremely high removal ratesPrinciples of Modern Grinding Technology ResearchGateMSE PRO™ Metallographic Samples Pregrinding Machine MSE Supplies offers a High Efficiency Metallographic Pre Mill Machine to help you simplify and speed up the metallographic samples preparation process In the process of metallographic sample preparation, the cut sample surface or the unprocessed sample surface are rough and unevenMSE PRO Metallographic Samples Pregrinding Machine

Temperature measurement in high efficiency deep grinding Machine

2005年9月1日 Temperature measurement in high efficiency deep grinding Machine Tools Manufacture, 45, 12311245 Prestress grinding has the potential to improve the SCC resistance of the surface2024年6月15日 Grinding surface quality is a key indicator to determine the performance of parts and the reliability of products During the grinding process, the precontrol technology makes appropriate adjustments in advance on its key aspects to improve the grinding surface quality Therefore, this paper constructs a datadriven precontrol system for grinding surface quality Precontrol of grinding surface quality by datadriven: a review2007年8月3日 High Efficiency Deep Grinding pre ssures and actual flow through the grinding zone Temperature measurement in high efficiency deep grinding Machine Tools Manufacture, 45, 12311245Process monitoring in high efficiency deep grinding HEDGHigh grinding efficiency: The grinding force is increased through hydraulic pressurization, improving the grinding efficiency, and the output is large Low energy consumption, saving 30–50% power consumption than ball millsEnergysaving and Efficient Vertical Roller Mill Fote

Pre Grinding Mill PreMilling Machine Large Flowrate

Our product is concerned by its high efficiency, high reliability and comprehensive benefit Our goal is to build a world center for developing, manufacturing, sales and aftersale Our obligations is to solve the customers 'problems regarding A man grinding on metal using an angle grinder, causing a lot of sparks Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool A wide variety of machines are used for grinding, best classified as portable or stationary: Portable power tools such as angle grinders, die grinders and cutoff saws; Stationary power tools such as bench Grinding (abrasive cutting) WikipediaHigh efficiency surface grinders are among PROFIMACH’s impressive range of Machine Tools Like all of PROFIMACH’s products, every single one of their surface grinders are intricately designed to totally accommodate the infinite demands that high mix production places on businesses of any size, no matter how big or smallSurface Grinding machine CNC Europe2024年4月18日 The grinding mechanism rotates at a high speed, using sharp blades or teeth to break down the buds into a fine, uniform grind The ground material is then collected in the bin for further processing or directly used for preroll production Increased Efficiency: A preroll grinder machine automates the grinding process, The Essential Guide To PreRoll Grinder Machines ShunTool

Grinding Machine: Types, Parts, Working Operations (With PDF)

2018年10月1日 Grinding Machine Definition A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the materialIt is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece Generally, the grinding is a type of finishing operation to make sure that there is high surface quality, 2021年3月31日 Grinding is widely known for its low material removal rates and high surface quality However, recent developments in production processes for cubic boron nitride (CBN) abrasive grains have led to commercially available grain sizes larger than 300 µm These superabrasive CBNgrains allow higher material removal rates during grinding of hardened High performance peel grinding of steel shafts using coarse 2024年10月5日 Highspeed grinding (HSG) is an advanced technology for precision machining of difficulttocut materials in aerospace and other fields, which could solve surface burns, defects and improve surface integrity by increasing the linear speed of the grinding wheel The advantages of HSG have been preliminarily confirmed and the equipment has been built for Highspeed grinding: from mechanism to machine tool2024年11月5日 Due to the advantages of high transmission efficiency, an accurate transmission ratio, and an extensive transmission power range, gears are extensively employed in automobiles, aerospace, rail traffic, robots, ship machinery, and other fields [1, 2]According to the use of the product, gears can be divided into three categories: automotive gears, industrial gears, and HighSpeed and LowNoise Gear Finishing by Gear Grinding and

.jpg)

Maximizing Efficiency with Automatic PreRoll Machines

Automated preroll machines have impacted the way good joints can be produced, making it easier for businesses to meet increasing demand while keeping labor costs in check Industrial preroll machines offer cannabis companies a pathway to scale their operations, improve efficiency, and ensure consistent product quality across every joint