Petroleum coke grinding aid manufacturer

.jpg)

Petroleum Coke Calcining Systems Metso

Also known as "green petroleum coke", calcined petroleum coke is very important to link the oil and metallurgical industries for multiple applications Metso's experience in petroleum coke calcining has fueled us to become a world Highly Efficient Petroleum Coke Grinder for Processing Industries The Petroleum Coke Grinder offered by Weifang Jinghua Powder Engineering Equipment Co, Ltd is a highefficiency China Petroleum Coke Grinder Manufacturer, Supplier JINGHUA2024年2月27日 Petroleum coke grinding machines encompass a variety of specialized equipment tailored to meet the unique requirements of petroleum coke processing These Petroleum Coke Grinding MachinesTerraSource Global’s crushers and feeders are crucial for petroleum coke processing at refineries and power plants, offering precise sizing, efficient material flow, and reduced operational Petroleum Coke TerraSource Global

Products GME Garcia Munte

Micronized petcoke is an evolved version of petroleum coke Thanks to the micronization system, a process developed by our organisation more than 10 years ago, the coke is provided with BP Plc, Phillips 66 Company, PJSC Lukoil, Royal Dutch Shell Plc, Indian Oil Corporation Ltd, Valero Energy Corporation, and Essar, among others, are the major players in the global Top 7 Petroleum Coke Manufacturers Companies in the WorldOur equipment, including Gundlach Crusher’s CagePaktor, MultiRoll Crushers, and NANOSIZR, is designed to handle wet, sticky materials while minimizing fines Jeffrey Rader’s Petroleum Coke Elgin Separation SolutionsAsbury is a worldwide reliable source for both green and calcined petroleum coke (CPC) products These highquality, nongraphitic carbons can be found in applications ranging from Cokes and Material Solutions Asbury Carbons Asbury Carbons

Coke Calcining Systems Metso Automation PDF Catalogs

Calcining of petroleum coke is done in the rotary kiln The kiln components consist of shell, tires, carrying stations, seals, refractory and a drive train which includes girth gear, pinion, speed Petroleum Coke You find here 9 suppliers from Germany and China Please obtain more information on spare parts, servicing, maintenance, All contact information of listed Petroleum Coke manufacturers, traders, suppliers and dealers are freely available to all users How do you rate the information on this page? 9 Reviews 60% Ads Petroleum Coke 9 Manufacturers, Traders SuppliersCalcined Petroleum Coke (CPC) is manufactured from Raw Petroleum Coke (RPC) by the process known as high temperature pyrolysis The process is carried out in a rotary or vertical kiln at temperatures exceeding 1300 deg C :: Welcome to Pioneer Carbon Company :: Calcined 2015年8月7日 Petroleum coke (PC) blend with coal is an attractive feedstock for combustion process The present work investigates the grinding characteristics of PC blend with coal in a laboratory ball mill to Grinding Characteristics of Coal and Petroleum Coke/Coal

Petroleum Coke Types, Uses and Specifications

2023年1月29日 Aluminium, Graphite Electrodes Manufacturing: Calcining the coke, by heating it in a rotary kiln at temperatures over 1370 °C, increases the carbon content of the coke thus making it suitable, (generally less than 2 wt% sulfur and less than 0:5% ash content), for use in the aluminium, graphite electrode, steel, titanium dioxide, and other carbon consuming industries2013年10月29日 Source: US Environmental Protection Agency, ScreeningLevel Hazard Characterization, Petroleum Coke Category, June 2011; and HW Nelson, Petroleum Coke Handling Problems, 1970 Notes: The process of “calcining” converts green coke to almost pure carbon, with a defined structure to produce carbon anodes for the aluminum industryPetroleum Coke: Industry and Environmental Issues CRS Reports2024年2月27日 Petroleum coke grinding machines play a pivotal role in unlocking the full potential of petroleum coke, enabling industries to achieve precise particle size distributions, enhance product quality, and optimize process efficiencyWith their advanced technology, versatility, and environmental benefits, these machines are driving innovation and progress Petroleum Coke Grinding MachinesFour Output: shot coke 3t/h4t/h ; sponge coke 4t/h5t/h 5 Provide completed grinding machine (together with crusher, conveyor tools and grinding machine) FLMa thousand grinding machine is suitable for petroleum coke, together with crusher, conveyor gear (including auger and powder pneumatic conveying),grinding machinePetroleum Coke Ring Roller Mill Producer

petroleum coke B2B companies and suppliers europages

petroleum coke B2B companies and suppliers europagesBuying Suncor petroleum coke Suncor markets its petroleum coke under Suncor Energy Marketing Inc, which is 100% guaranteed by Suncor Energy Inc Petroleum coke sales are typically structured as shortterm fixed price contracts or spotfixed price (cargobycargo or monthbymonth) contracts Access to North American marketsPetroleum coke – Supply and Trading SuncorGrinding: The coarsely crushed petroleum coke is sent to the HGM series petroleum coke superfine grinder for grinding The ultrafine pulverizer uses highspeed rotating blades and fixed grinding discs to further grind raw materials into fine particles through the effects of shearing, friction, and impactPetroleum Coke Ultrafine PulverizerManufacturer of Petroleum Coke Non Calcined Petroleum Coke, Calcined Petroleum Coke, Calcined Petroleum Coke Grinding and Sizing Calcine Petcoke offered by Atul Coke, Jamnagar, GujaratNon Calcined Petroleum Coke Manufacturer from Jamnagar

Comparisons of Dry Grinding Kinetics of Lignite, Bituminous

2013年5月15日 In this study, the effect of fuel type was investigated on the lignite and the bituminous coal and the petroleum coke samples using GÖltas cement factory (Isparta/Turkey) at batch grinding About Tirupati Processors, Manufacturer, Supplier of Calcined Petroleum Coke, Grinding Petcoke, Sizing Petcoke from Jamnagar, Gujarat Product / Services Products / ServicesTirupati Processors in Jamnagar Manufacturer of Welcome to Tirupati Prosessor is one of the leading manufacture of Calcined Petroleum Coke The sister concern was in the field of manufacturing of MESH POWDER ""Tirupati Processors floated in 2009 by Mrs Namrata Pankaj Samani and managed by Mr Pankaj Samani and located at Village Zakhar, Dist Jamnagar State – GujaratCalsined Petcock, Sizeing Petcock, Grinding Petcock Tirupati List of Top Petroleum Coke Companies including BP plc, Chevron Corporation, ConocoPhillips Company, Exxon Mobil The company produces and sells petroleum coke as a fuel source for industrial processes like cement manufacturing and power generation The company is headquartered in San Ramon, California, and is active in over 180 Top Petroleum Coke Companies IMARC Group

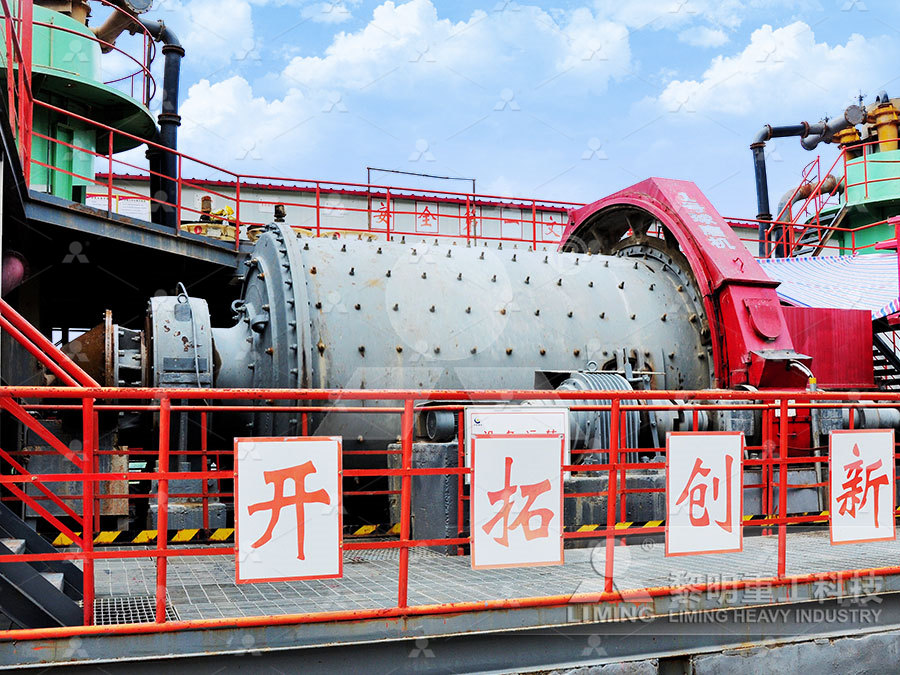

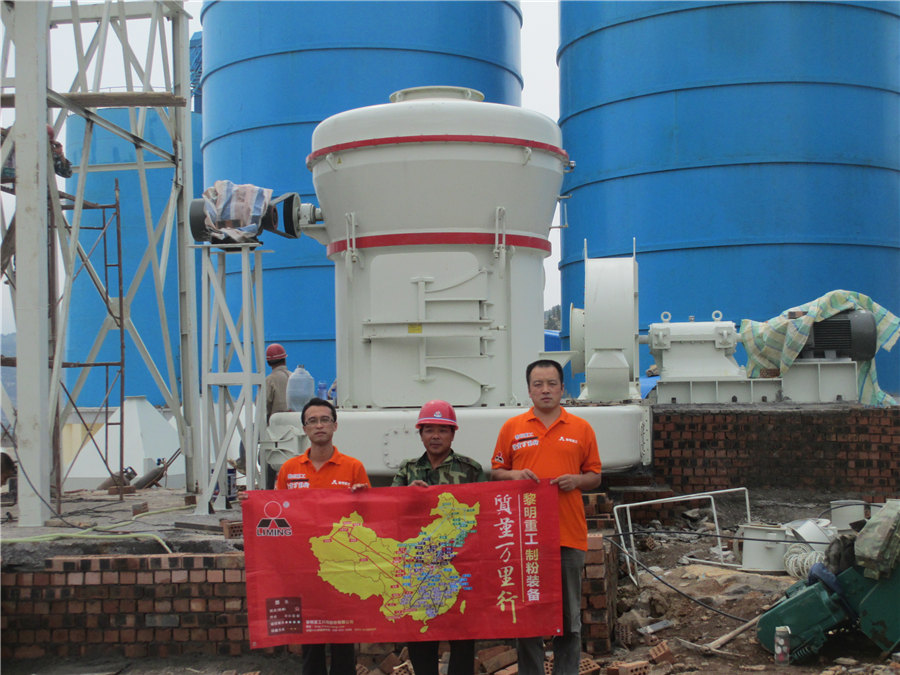

Types of grinding mills for petcoke grindingTypes of grinding

2021年6月11日 There are many pulverizers for grinding petroleum coke, and the supply of environmentally friendly pulverizer equipment meets the needs of different fineness and China famous professional manufacturer of micronized powder technology ADDRESS No19, Fuqing Rd, Pudong New Area, Shanghai, China CONTACT US +86 sales@ 2014年12月12日 Coke is used as a feedstock in coke ovens for the steel industry, for heating purposes, for electrode manufacture, and for the production of chemicals Petroleum coke (petcoke) is the graytoblack solid carbonaceous residue left by the destructive distillation of petroleum residuaCOKE, CARBON BLACK, AND GRAPHITE Handbook of Petroleum 2023年12月1日 This paper explored the effect of different grinding media on the property improvements of petroleum coke with rare earth carbonate The experimental results were discussed in combination with thermodynamic and kinetic analyses The strengthening mechanism was analyzed by Fourier transform infrared spectroscopy (FTIR) and scanning Rare Earth Addition and Grinding Medium Coupling Vanajaa Enterprises Carbon Additive, Petroleum Coke Coconut Shell Charcoal Manufacturer from Coimbatore, Carbon Additive, Petroleum Coke Coconut Shell Charcoal Manufacturer from Coimbatore, Tamil Nadu, India Vanajaa Enterprises Ganapathy, Coimbatore, Tamil Nadu GST No 33ABVPV5399M1ZD TrustSEAL Verified Call 57% Carbon Additive and Petroleum Coke Manufacturer Vanajaa

Home Page carbon resources

Incorporated in 1991, our manufacturing facilities are spread across 4 states in India Raw petroleum coke or green coke is calcined at temperatures as high as 1400 degree celsius This process removes the volatiles and a premium carbon material, Calcined Petroleum Coke2019年11月9日 Petroleum coke is the abbreviation of coke or petcoke, is a final carbonrich solid byproduct of oil refining process produced by Petroleum coke grinding mill, and can be used in carbon, cement, chemical, smelting and other industries The usage of petroleum coke is determined by its classificationPetroleum Coke Classifications And Applications gkmill2024年4月1日 Fig 4 shows the FTIR profiles of petroleum coke and its semicoke, which can be used to determine the chemical structure and function of petroleum coke and semicoke The profiles of petroleum coke before and after carbonization vary only slightly in the overall trend, in which spectral bands only appear or disappear near 3036 cm −1 , 1440 cm −1 and 1086 cm Study on the preparation of high valueadded activated carbon The organic grinding aid is used to prevent the ground petcoke particles from reagglomeration during and after the milling process Process for improving the grinding efficiency of petroleum coke ATA22/2014: : Publications (1) Publication Number Method for manufacturing highdensity carbon molded bodies JPSA Method of enhancing the dry grinding efficiency of petcoke

What grinding equipment is needed for petroleum coke

2022年3月29日 The calcined petroleum coke (or after onetime crushing) is continuously and evenly sent to the main machine grinding room for grinding through the skirt belt feeder The ground fine powder is sent to the classifier for classification under the action of fan air flow, and the fine powder with qualified fineness enters the collection stage through the air outlet pipe2017年4月28日 FLM1000 grinding machine for petroleum coke feature: 1 Grinding machine is based on petroleum coke characteristics, using numerical simulation software to design the most suitable crushing and Petroleum coke Ring Roller Mill Manufacturer by feng li2021年4月2日 Results showed that grinding improved gasification and wet grinding had more pronounced effect than dry grinding When wet grinding of petcoke and additive took place together, the active metals in additive were retained in the solid phase, thereby causing a high catalytic reactivity to the cokeCO 2 reactionPetcoke Gasification: Challenges and Future Prospects2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low cost This article provides a review of the history and use of calcined petroleum coke for anode production and describes the different calcining technologies used The History and Future Challenges of Calcined Petroleum Coke Production

Changing the Fineness of Calcined Petroleum Coke with Ball

2019年2月16日 Calcined Petroleum CokePetroleum coke CPC of 75% passing 75 µm is typically mixed with pitchPitch to form the anodes “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, GermanyEstablished in year 2010, “Atul Coke” is manufacturing Petroleum Coke Powder,Petroleum Coke etc We are wellsupported by our team of highly skilled professionals who possess rich industry experience in their respective domains of business operations Their strong support makes us able to provide the utmost level of satisfaction to our clientsAtul Coke Manufacturer from Lalpur, Jamnagar, India About Us2020年5月22日 Raymond Mill For Grinding 300 Mesh Petroleum Coke Powder 15:45; HCM; Sincerely invite new and old customers and friends to visit the grinding mill manufacturer to know the details of professional petroleum coke grinding mill equipment Tel:+86 Email: nd Mill For Grinding 300 Mesh Petroleum Coke PowderPetroleum Coke You find here 9 suppliers from Germany and China Please obtain more information on spare parts, servicing, maintenance, All contact information of listed Petroleum Coke manufacturers, traders, suppliers and dealers are freely available to all users How do you rate the information on this page? 9 Reviews 60% Ads Petroleum Coke 9 Manufacturers, Traders Suppliers

:: Welcome to Pioneer Carbon Company :: Calcined

Calcined Petroleum Coke (CPC) is manufactured from Raw Petroleum Coke (RPC) by the process known as high temperature pyrolysis The process is carried out in a rotary or vertical kiln at temperatures exceeding 1300 deg C 2015年8月7日 Petroleum coke (PC) blend with coal is an attractive feedstock for combustion process The present work investigates the grinding characteristics of PC blend with coal in a laboratory ball mill to Grinding Characteristics of Coal and Petroleum Coke/Coal 2023年1月29日 Aluminium, Graphite Electrodes Manufacturing: Calcining the coke, by heating it in a rotary kiln at temperatures over 1370 °C, increases the carbon content of the coke thus making it suitable, (generally less than 2 wt% sulfur and less than 0:5% ash content), for use in the aluminium, graphite electrode, steel, titanium dioxide, and other carbon consuming industriesPetroleum Coke Types, Uses and Specifications2013年10月29日 Source: US Environmental Protection Agency, ScreeningLevel Hazard Characterization, Petroleum Coke Category, June 2011; and HW Nelson, Petroleum Coke Handling Problems, 1970 Notes: The process of “calcining” converts green coke to almost pure carbon, with a defined structure to produce carbon anodes for the aluminum industryPetroleum Coke: Industry and Environmental Issues CRS Reports

.jpg)

Petroleum Coke Grinding Machines

2024年2月27日 Petroleum coke grinding machines play a pivotal role in unlocking the full potential of petroleum coke, enabling industries to achieve precise particle size distributions, enhance product quality, and optimize process efficiencyWith their advanced technology, versatility, and environmental benefits, these machines are driving innovation and progress Four Output: shot coke 3t/h4t/h ; sponge coke 4t/h5t/h 5 Provide completed grinding machine (together with crusher, conveyor tools and grinding machine) FLMa thousand grinding machine is suitable for petroleum coke, together with crusher, conveyor gear (including auger and powder pneumatic conveying),grinding machinePetroleum Coke Ring Roller Mill Producerpetroleum coke B2B companies and suppliers europagespetroleum coke B2B companies and suppliers europagesBuying Suncor petroleum coke Suncor markets its petroleum coke under Suncor Energy Marketing Inc, which is 100% guaranteed by Suncor Energy Inc Petroleum coke sales are typically structured as shortterm fixed price contracts or spotfixed price (cargobycargo or monthbymonth) contracts Access to North American marketsPetroleum coke – Supply and Trading Suncor

Petroleum Coke Ultrafine Pulverizer

Grinding: The coarsely crushed petroleum coke is sent to the HGM series petroleum coke superfine grinder for grinding The ultrafine pulverizer uses highspeed rotating blades and fixed grinding discs to further grind raw materials into fine particles through the effects of shearing, friction, and impact