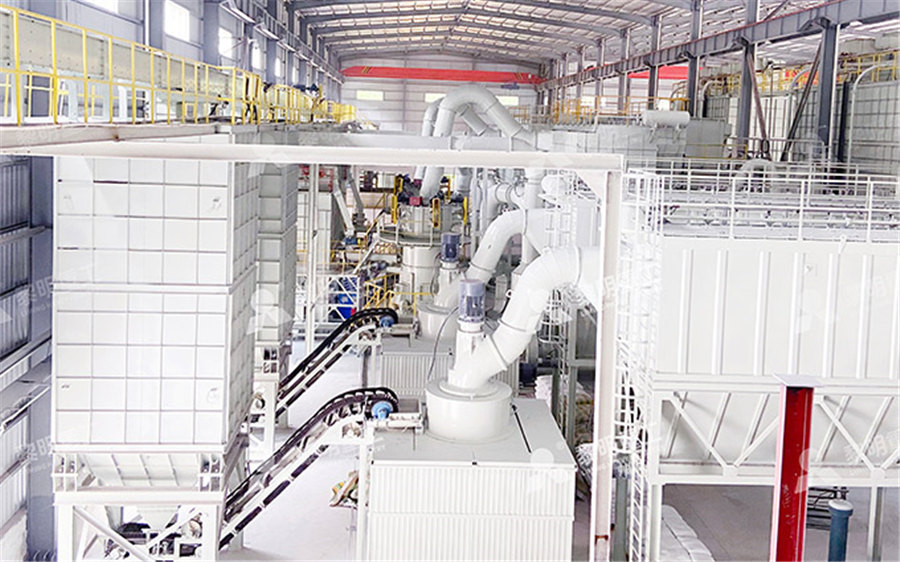

Concrete limestone powder production line equipment

Limestone Grinding Mill Plant TAYMACHINERY

The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields After ultrafine grinding, highquality limestone is widely used in the manufacture of power plant desulfurizers, concrete admixtures, paper, rubber and other products Materials: Calcium limestone grinding plant CHAENGThe lime production line is composed of the vibrating feeder, jaw crusher, hammer crusher, impact crusher, circular vibrating screen and belt conveyor Depending on material properties and production requirements, we offer Lime Production Line Limestone Equipment 2015年9月1日 As a leading grinding equipment manufacturer in Asia, ZK machinery has already established the concrete with limestone power project production line for hundreds of building Henan Zhengzhou Mining Machinery

Limestone Powder: Uses, Price and Production

2020年3月7日 Limestone, a kind of natural mineral resource, is a sedimentary rock formed by inorganic remains such as shells or bones And people always see it in warm and shallow water fields We all know that the main ingredient 2018年12月20日 Concrete is the largest building materials due to its prominent adaptability, wide availability of raw materials, and low maintenance cost [1]However, production of concrete has also caused heavy environmental pressure as a result of its global contribution to CO 2 emission associated with approximately 25 billion tons of concrete produced on the planet A review on effects of limestone powder on the properties of concreteThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERYNon autoclaved lightweight aerated concrete is a type of lightweight concrete which is used to produce blocks and replace bricks NAAC is lighter then conventional concrete It is formed by using portland cement, fly ash, limestone, aluminum powder and water Aerated concrete has a good strength, durability, good thermal and sound insulationLightweight concrete blocks production equipment Pioner

Effect of Dolomite Limestone Powder on the Compressive Strength of Concrete

Effect of dolomite limestone fine powder (specific surface 5500cm2/g) content on cement concrete compression strength: 14 and 28 days age 778 Olesia Mikhailova et al / Procedia Engineering 57 2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc Raw material conveying system The raw material, including limestone, 6 Cement Equipment For Dryprocess Cement Production Line2024年8月26日 At present, most of the limestone powder used in the building materials industry is limestone or stone chips generated in the production of aggregates, etc, which are ground to meet the specified fineness requirements 1 Limestone grinding process There are two main processes for limestone grinding:Limestone Powder Grinding Process ALPA Powder Equipment2017年4月19日 Limestone powder is produced by grinding limestone into powder, and it has been used as a kind of mineral admixture in cement or concrete production for various purposes in many years [1–3]In addition to the relatively low cost and energy consumption [] and reduced global warming potential [5, 6], it may improve the early strength and workability of concrete [1, Longterm properties of concrete containing limestone powder

.jpg)

Fully Automatic Dry Powder Wall Putty Gypsum Limestone Production

Fully Automatic Dry Powder Wall Putty Gypsum Limestone Production Construction Material Cement Sand Concrete Tile Adhesive Plaster Mortar Mixing Equipment, Find Details and Price about Concrete Batching Process Putty Spray Machine from Fully Automatic Dry and developed a complete set of mortar production line equipment with advanced limestone powder are investigated in studies on pastes For the 10 % limestone mixtures, concretes are prepared, this time with a volumetric replacement of limestone powder for cement, and compared to a 100 % ASTM C150 Type I/II with MultiScale Investigation of the Performance of Limestone in Concreteand concretes are each formulated with limestone powder replacement for a significant portion of their cement paste component, achieving cement reductions of up to 28 % in concrete, for example For these mixture modifications, the watertocement mass ratio ( w/c ) Minimizing Paste Content in Concrete Using Limestone Powders In addition to cement manufacturing equipment with production capacity of 6000 t/d, 5000 t/d, and 2500 t/d, we can also offer EPC contractor service Following is a detailed description of the production process of the production line Raw Cement Production Line Cement Plant Equipment

.jpg)

Minimizing Paste Content in Concrete Using

2016年1月6日 However, a more abundant material substitute would be limestone powder, created from the same limestone that is currently heavily employed in cement production as the primary source of calcium oxideand concretes are each formulated with limestone powder replacement for a significant portion of their cement paste component, achieving cement reductions of up to 28 % in concrete, for example For these mixture modifications, the watertocement mass ratio ( w/c ) Minimizing Paste Content in Concrete Using Limestone Powders Dolomitic Limestone Powder: Cement Substitute in the Production of Structural Concrete Paving Blocks Israel A Baguhin College of Engineering and Architecture University of Science and Technology of Southern Philippines – Cagayan de Oro Cagayan de Oro City, 9000 Philippines Date received: October 18, 2021Dolomitic Limestone Powder: Cement Substitute in the Production 2024年9月6日 Concrete is the most commonly used solid material on the planet and is typically composed of 7–15 % cement by volume [1]However, with the construction industry's ongoing advancements, it is becoming increasingly important to prioritize sustainability and reduce CO 2 emissions [2]Ordinary Portland cement (OPC) is the most widely used cement globally, but Evaluating carbonation resistance and microstructural behaviors of

.jpg)

Cement Production Line Cement Manufacturing Plant AGICO

AGICO dry process cement production line comprehensively adopts the IT technology, multifunction grinding system, newtype wearresisting and heatresisting materials, mechanical powder conveying device, and some other modern technologies to realize quality cement production It has the characteristic of energy saving, high efficiency, environmental protection, 2024年6月29日 Product: Limestone drying and grinding line Model: 8t/h Voltage Frequency: 380V/50Hz Limestone powder is a product obtained by crushing and processing limestone Limestone powder that meets engineering requirements is widely used in the production of asphalt mixturesZOOMLINE New purchase of mineral powder production line2024年2月23日 The production of limestone powder involves a series of carefully controlled steps to transform raw limestone into a versatile and valuable material Limestone powder is widely used in the construction industry as a key component in the production of cement and concrete 450TPH Limestone Gravel Production Line in Mexico;Introduction of limestone powder making process and application2024年3月5日 The objective of this study is to investigate the performance of normal and highstrength concretes including limestone powder (LP) through their mechanical properties Moreover, sustainable flat plates made of these concretes were investigated through their punching strength For this purpose, two different types of concrete (normal and high Effectiveness of Limestone Powder as a Partial Replacement of

Limestone crushing, sand making and grinding process

2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other China Limestone Production Plant wholesale Select 2024 high quality Limestone Production Plant products in best price from certified Chinese Production Equipment manufacturers, Fixed Quarry Aggregate Production Line Limestone Basalt Quartz Concrete Marble Gravel Crushing Plant Stone Crusher Machinery US$ 79999 / Set 1 Set Limestone Production Plant MadeinChina2021年2月25日 Powder type of selfcompacting concrete (SCC) needs high cement content to achieve selfcompactibility, this will be undesirable in tropical climate of Sudan due to implication of high hydration heatEffects of Limestone Powder on Selfcompacting Concrete PropertiesThermal stability: Limestone powder is thermally stable at high temperatures, making it an ideal material for use in the production of cement, concrete, and other construction materials Alkaline properties: Limestone powder has alkaline properties that make it effective in neutralizing acidic soils, which can improve soil quality and plant growthLimestone Powder Suppliers in India: Quality Limestone Powder

Impact crusher used in limestone aggregate making production line

2024年2月22日 Limestone aggregate, a cornerstone material in construction, owes its versatility and durability to the crushing equipment utilized in its production process Among these, impact crushers stand out as vital tools in transforming raw limestone into the fine and coarse aggregates essential for building sturdy structures2024年1月11日 Equipment Configuration Of Limestone SandMaking Plant The equipment for the limestone sand production line mainly includes a vibrating feeder, jaw crusher, sand making machine, circular vibrating screen, sand washing machine, etc The vibrating feeder is responsible for evenly and quantitatively delivering raw materials to the stone crusherLimestone Crushing And SandMaking Plant Eastman Rock Cement and Concrete Production Limestone powder is a main ingredient in cement It acts as a filler and improves the cement’s quality This makes the cement stronger, These deposits are mined and quarried with special equipment and methods This ensures the limestone is taken out in a controlled and sustainable way9 important Uses of limestone powderOverall, the process of making cement involve the use of limestone and clay which undergoes four stages and equipment while concrete production requires only one process and tool In the first digram, limestone and clay are added into a crusher where they are crushed into a powder and then thoroughly mixed in a mixerIELTS Diagram: Model Answer Band Score 9 with Tips

.jpg)

Properties of Composite Modified with Limestone Powder for 3D Concrete

2020年7月8日 21 Research Assumptions For the purpose of the study a reference mix (B800/LP0) was chosen The highperformance concrete mix has total of 800 kg/m 3 of binder, including fly ash and silica fume The mix design was a modification of a mix found in [7, 22]Mix performance and applicability in 3D printing was tested previously []For the purpose of the China Concrete Equipment wholesale Fully Automatic Dry Powder Wall Putty Gypsum Limestone Production Construction Material Cement Sand Concrete Tile Adhesive Plaster Mortar Mixing Easy DeMoulding Panel Machine Lightweight Precast Wall Concrete Wall Panels Making Machine/ Production Line/Equipment for Sale US$ 1500025000 / Piece 1 Concrete Equipment MadeinChina2020年3月7日 Limestone, a kind of natural mineral resource, is a sedimentary rock formed by inorganic remains such as shells or bones And people always see it in warm and shallow water fields We all know that the main ingredient Limestone Powder: Uses, Price and Production2018年12月20日 Concrete is the largest building materials due to its prominent adaptability, wide availability of raw materials, and low maintenance cost [1]However, production of concrete has also caused heavy environmental pressure as a result of its global contribution to CO 2 emission associated with approximately 25 billion tons of concrete produced on the planet A review on effects of limestone powder on the properties of concrete

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Non autoclaved lightweight aerated concrete is a type of lightweight concrete which is used to produce blocks and replace bricks NAAC is lighter then conventional concrete It is formed by using portland cement, fly ash, limestone, aluminum powder and water Aerated concrete has a good strength, durability, good thermal and sound insulationLightweight concrete blocks production equipment PionerEffect of dolomite limestone fine powder (specific surface 5500cm2/g) content on cement concrete compression strength: 14 and 28 days age 778 Olesia Mikhailova et al / Procedia Engineering 57 Effect of Dolomite Limestone Powder on the Compressive Strength of Concrete2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc Raw material conveying system The raw material, including limestone, 6 Cement Equipment For Dryprocess Cement Production Line

.jpg)

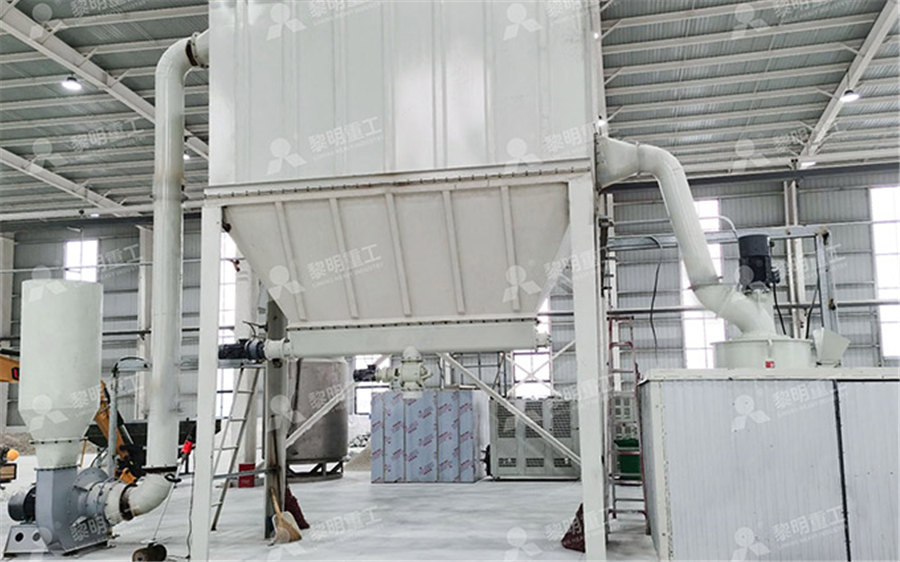

Limestone Powder Grinding Process ALPA Powder Equipment

2024年8月26日 At present, most of the limestone powder used in the building materials industry is limestone or stone chips generated in the production of aggregates, etc, which are ground to meet the specified fineness requirements 1 Limestone grinding process There are two main processes for limestone grinding:2017年4月19日 Limestone powder is produced by grinding limestone into powder, and it has been used as a kind of mineral admixture in cement or concrete production for various purposes in many years [1–3]In addition to the relatively low cost and energy consumption [] and reduced global warming potential [5, 6], it may improve the early strength and workability of concrete [1, Longterm properties of concrete containing limestone powderFully Automatic Dry Powder Wall Putty Gypsum Limestone Production Construction Material Cement Sand Concrete Tile Adhesive Plaster Mortar Mixing Equipment, Find Details and Price about Concrete Batching Process Putty Spray Machine from Fully Automatic Dry and developed a complete set of mortar production line equipment with advanced Fully Automatic Dry Powder Wall Putty Gypsum Limestone Production limestone powder are investigated in studies on pastes For the 10 % limestone mixtures, concretes are prepared, this time with a volumetric replacement of limestone powder for cement, and compared to a 100 % ASTM C150 Type I/II with MultiScale Investigation of the Performance of Limestone in Concrete