How to prevent wear at the export of coal mill

.jpg)

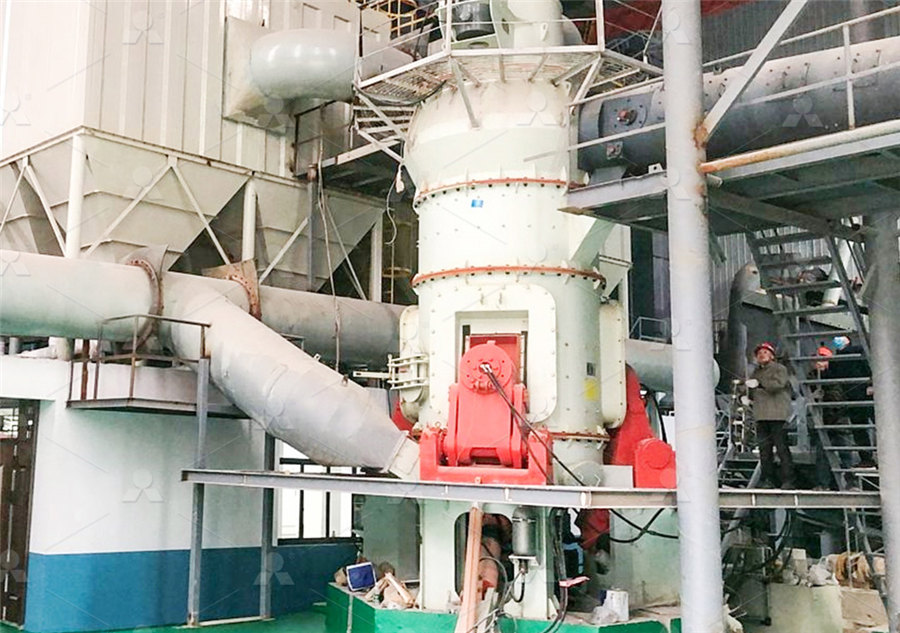

Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal

Coal mills, also known as pulverizers, play a critical role in power plants by grinding coal into fine powder, which is then used in various pyroprocesses These mills pose significant safety risks Ensuring the safe operation of coal mills is crucial for preventing accidents, maintaining plant Loading shovels are subject to increased wear in quarries Therefore, linings made of KALMETALL HB, KALMETALL and KALCAST provide good protection Dump trucks require Solutions for Wear Protection in Mining and Processing IndustryRoutine Checks: Perform regular inspections of all components, including grinding rollers, grinding tables, and the mill’s structural integrity and explosion pressure shock resistance Look for Ensuring Safety in Coal Mills – Best Practices and Precautionsto prevent wear COaL MILLs and PF LInEs: LOCTITE wearresistant coatings COaL BuRnER nOzzLE TIPs: LOCTITE extreme high temperature and erosion resistant coatings hkel – Maintain, Repair, Rebuild, Protect Solutions for Conventional

.jpg)

A Wear Condition Monitoring Model of Coal Mill Grinding Roller

2020年12月21日 In order to realize the monitoring of grinding roller wear state of coal mill in power plant as well as improve the reliability and safety of equipment, it is essential to build a modifying the profile can balance the wear rate in the whole mill, minimize unexpected downtime, and prevent damage to the mill A lining that does not fit properly will not protect the mill well It Three factors that determine the wear life and performance of mill However, the process involves significant safety risks due to the combustible nature of coal dust and the mechanical hazards posed by the operation of the mill Ensuring safety during coal Aspects of Coal Mill Safety Coal Mill Safety, Explosion and Fire Safe coal handling practices are designed to ensure that the fuel remains intact throughout its journey from the mine until the point at which it is ignited in the boiler It takes as little as 14 kg COAL HANDLING SAFETY Land Instruments International

.jpg)

COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS PEC

Walls should be washed down frequently to prevent dust accumulation, and welding or electrical repair work should not be conducted in an enclosed area during unloading operations or if 2024年11月21日 Operators should implement a routine maintenance schedule that includes checking for signs of wear, such as cracks, warping, or loss of material When wear is Understanding Coal Mill Wear Parts: Importance and MaintenanceSafe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding system is nothing more than a mirageOptimisation of coal mill systems, with fire and explosion Coal warms our hospitals and schools, ripens our tomatoes, makes roses bloom, turns ironsand into steel, dries milk powder for export, and generates electricity when hydro lakes are low and gas production sputters Coal also releases Why are we still burning coal? New Zealand Geographic

Understanding coal quality and the critical importance of

2022年11月1日 In general, the thermoplastic range of coal spans the bituminous rank range (the caking coals, with coking coals being a subset of the caking coals), with the fluidity peaking in the upper high volatile A to medium volatile bituminous rank range (Fig 6) 15 Various tests for fluidity and expansion are described by Davis (1978), Berkowitz, 1979, Berkowitz, 1985, Zimmerman For now, coal is a $50billionayear export industry How long until its rivers of gold run dry? This question, and others about the future of coal, drive some of the deepest divisions in modern Australian coal: What will happen to $50bayear industry?2023年6月12日 Our mission is to provide highquality coal and diesel to our customers while prioritizing safety, sustainability, and reliability Our vision is to be the leading supplier of coal and diesel, recognized for our commitment to safety, sustainability, and innovation National Coal Suppliers is a reliable South African coal supplierSouth African Coal Mining Techniques2024年3月16日 A vertical coal mill functions by introducing coal into a rotating table, checks and adjustments of the alignment of grinding rollers and tables are necessary to ensure proper operation and prevent uneven wear Tightening bolts and fasteners and making necessary adjustments help maintain stability and alignment for optimal How Does a Vertical Coal Mill Work

.jpg)

Analysis of the Coal Milling Operations to the Boiler Parameters

2020年4月2日 The need to operate a boiler efficiently in today's environment is at the top of many plant owners and operators lists Unfortunately, operating a boiler efficiently and meeting local emission 2019年11月7日 Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main operating parameters before modificationTransform the Optimization and transformation of 300MV units steel ball coal mill 2022年6月7日 Given that it is possible, as discussed later in this report, to produce lower methaneintensity coal, this could have consequences for the resilience of Australia’s current trade relationships if competitor coal export countries are faster to adopt methane reduction measures Emissions measurement and regulation in AustraliaTackling Australia’s Coal Mine Methane Problem EmberCoal dust explosions are among the severe hazards in industries using coal, posing significant risks to personnel and infrastructure These explosions occur when fine coal particles become airborne and come into contact with a heat source in an enclosed environment, leading to a rapid combustion event Given the catastrophic potential of such incidents, robust measures for coal Coal Dust Explosion Protection: Ensuring Safety in industries using

The future of coal in a carbonconstrained climate

2020年7月27日 It is understood that a coal phaseout can only succeed if it takes into account social objectives and priorities The necessity of a ‘just transition’ is widely acknowledged (Box 1)Such Coal grinding is a critical process in various industries, particularly in power generation and cement production However, the process involves significant safety risks due to the combustible nature of coal dust and the mechanical hazards posed by the operation of the mill Ensuring safety during coal grinding is essential to prevent accidents, exAspects of Coal Mill Safety Coal Mill Safety, Explosion and Fire This article explores the key aspects of coal mill safety, including potential hazards, preventive Wear and tear on mechanical components can lead to Inerting involves introducing an inert gas, such as nitrogen or carbon dioxide, to reduce the oxygen concentration and prevent coal dust explosions These systems should be Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal 2023年7月15日 12 CO2 Emissions Based on the energy use in China, CO2 emission is calculated by using emission factors from IPAC model Figure 6 presents the CO2 emission from energy activities from 1990 to 2021 Due to the rebound in coal use, China’s carbon emissions have reached a record high in 2021 and may enter a carbon emissions plateau in the next few Clean Coal Technologies: Transition to a Low Emission Future

.jpg)

Dust Explosions: Understanding the Risks and Preventive Measures Coal

Dust explosions pose significant hazards in various industries, often leading to catastrophic consequences including loss of life, substantial property damage, and prolonged operational disruptions Understanding the mechanics behind dust explosions, the conditions under which they occur, and the measures necessary to prevent them is crucial for ensuring workplace safety2009年1月1日 This book details advances in the production of steam and the utilization of all types of fuels Section 1 covers Steam Fundamentals including thermodynamics, fluid mechanics, heat transfer CFD Modeling of MPS Coal Mill for Improved Performance and Safety2021年5月10日 The phaseout of coal will bring fundamental changes to the industry, especially in the lives and jobs of workers In Mpumalanga, where most coal mining operations and coalfired power stations Get the shovels out: Death of the coal industry must bring new 2021年12月1日 This article summarizes lessons learnt from 15 case studies on the political economy of coal following one integrated framework It proposes four country categories that show comparable properties to analyze the political economy of coal, including countries that i) phase out coal, ii) phase in coal, iii) are established users and iv) depend on coal exportsThe political economy of coal: Lessons learnt from 15 country

The Changing Global Market for Australian Coal

2019年9月19日 Many of Australia's key thermal coal export destinations, including China, Japan and South Korea, are transitioning away from coalpowered electricity generation A continuation of this trend would be likely to weigh on coal export emissions in coalfired power plants, Riley Power Inc (RPI), a Babcock Power Inc (BPI) company has been actively developing mill system technology to achieve better coal fineness, increased capacity, greater reliability, and longer wear life The effort has improved the design of low, medium, and highCoal Pulverizer Design Upgrades to Meet the Demands of Low 2021年12月1日 Coal remains an important future source of the energy mix for many economies and this paper poses questions about the overall ability of policy instruments to mitigate the coal mining externalities Combining a systematic literature review (including of grey literature) Coal mining and policy responses: are externalities appropriately From 2022 to 2023, the value of exported coal declined by 226% starting from $2451 billion The 5 biggest exporters of coal are Australia, Indonesia, Russia, United States of America, and Canada Collectively, those 5 countries shipped 811% of the total value of coal sold on international markets during 2023Coal Exports by Country 2023

The Inferential predictive control method of coal mill IEEE

2016年1月18日 Next, the paper estimates the coal outlet mass flow of the coal mill by using extended Kalman filter (EKF), and the result is compared with the coal flow instruction Finally, we take the estimation of coal outlet mass flow as the new controlled variable and use inferential predictive control method to solve the coal mill control problemsAs one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperatureEffect of mill outlet temperature on the coal volatile matterThis is the official website of Coal Ministry, Government of India You can find information related Tenders, Notices, latest updates pertaining to Ministry of Coal, Government of India Import and Export As per the present Import policy, coal can be freely imported Ministry of Coal, Government of India• Coal characteristics profoundly influence risk – Lower rank coals are generally more easily ignited inside the coal mill – High volatile matter and highly reactive coals encourage preignition inside the mill – Higher moisture content requires temperature extremes inside the millMill Inerting and Pulverizer/Mill Explosion Mitigation

Modeling of Coal Mill System Used for Fault Simulation

2020年4月7日 The main task of a coal mill system is to prov ide qualified fuel for the pulverized coal boiler In partial cold primary air is pressurized by the sealing fan to prevent the leakage of coal 2 Why stockpile? 6 IEA Coal Research Stockpiling of coals is carried out at a number of points along the transport chain to the end user: at coal mines; at coal preparation plants; at transhipment points and terminals importing or exporting coals; andManagement of coal stockpiles ICSC2016年1月7日 Members will be aware of the issues involving self heating and methane emitting coal cargoes, which have recently been originating from Indonesia The logistics of dealing with coal cargoes apply to all regardless of origin Coal Coal has its origins as vegetable matter which has been subjected to heat and pressure over timeCarriage of coal cargoes: Selfheating and explosion risks2022年5月19日 The entire cycle of coal—from its extraction, transport and export, to its burning or combustion—causes irreversible damage to people One of the main impacts of coal mining is the degradation of air quality, which in turn violates the rights to health, life and a healthy environment, generating high rates of morbidity and mortality5 reasons to end coal extraction and use Interamerican

Optimisation of coal mill systems, with fire and explosion

Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding system is nothing more than a mirageCoal warms our hospitals and schools, ripens our tomatoes, makes roses bloom, turns ironsand into steel, dries milk powder for export, and generates electricity when hydro lakes are low and gas production sputters Coal also releases Why are we still burning coal? New Zealand Geographic2022年11月1日 In general, the thermoplastic range of coal spans the bituminous rank range (the caking coals, with coking coals being a subset of the caking coals), with the fluidity peaking in the upper high volatile A to medium volatile bituminous rank range (Fig 6) 15 Various tests for fluidity and expansion are described by Davis (1978), Berkowitz, 1979, Berkowitz, 1985, Zimmerman Understanding coal quality and the critical importance of For now, coal is a $50billionayear export industry How long until its rivers of gold run dry? This question, and others about the future of coal, drive some of the deepest divisions in modern Australian coal: What will happen to $50bayear industry?

.jpg)

South African Coal Mining Techniques

2023年6月12日 Our mission is to provide highquality coal and diesel to our customers while prioritizing safety, sustainability, and reliability Our vision is to be the leading supplier of coal and diesel, recognized for our commitment to safety, sustainability, and innovation National Coal Suppliers is a reliable South African coal supplier2024年3月16日 A vertical coal mill functions by introducing coal into a rotating table, checks and adjustments of the alignment of grinding rollers and tables are necessary to ensure proper operation and prevent uneven wear Tightening bolts and fasteners and making necessary adjustments help maintain stability and alignment for optimal How Does a Vertical Coal Mill Work2020年4月2日 The need to operate a boiler efficiently in today's environment is at the top of many plant owners and operators lists Unfortunately, operating a boiler efficiently and meeting local emission Analysis of the Coal Milling Operations to the Boiler Parameters2019年11月7日 Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main operating parameters before modificationTransform the Optimization and transformation of 300MV units steel ball coal mill

Tackling Australia’s Coal Mine Methane Problem Ember

2022年6月7日 Given that it is possible, as discussed later in this report, to produce lower methaneintensity coal, this could have consequences for the resilience of Australia’s current trade relationships if competitor coal export countries are faster to adopt methane reduction measures Emissions measurement and regulation in AustraliaCoal dust explosions are among the severe hazards in industries using coal, posing significant risks to personnel and infrastructure These explosions occur when fine coal particles become airborne and come into contact with a heat source in an enclosed environment, leading to a rapid combustion event Given the catastrophic potential of such incidents, robust measures for coal Coal Dust Explosion Protection: Ensuring Safety in industries using