HOME→Calcium carbonate shaping equipment Calcium carbonate shaping equipment Calcium carbonate shaping equipment

Calcium carbonate shaping equipment Calcium carbonate shaping equipment Calcium carbonate shaping equipment

Calcium Carbonate Manufacturing Process and Equipment

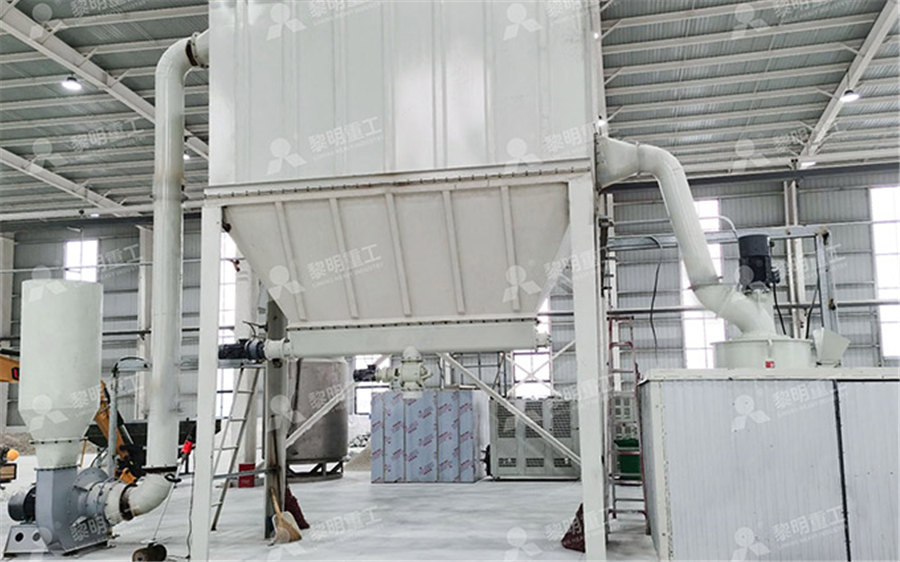

Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years) Chalk occurs as a microcrystalline material and has 展开What is calcium carbonate plant? Calcium carbonate processing plant is a production line that obtaining ground calcium carbonate powder by grinding limestone or marble Usually there are Customize Suitable Calcium Carbonate Plant DASWELLCarmeuse Systems supports precipitated calcium carbonate (PCC) producers by providing unmatched lime handling expertise, slaking equipment, and comprehensive solutions for your operationPrecipitated Calcium Carbonate Carmeuse Systems2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has Heavy calcium carbonate grinding, surface modification

Calcium Carbonate Grinding Union Process

Used as both an antacid and a dietary calcium supplement, calcium carbonate provides health benefits for increased bone density, suppression of acid reflux and a variety of other health issues Among other things, it is used as a 2017年11月1日 Tests were also performed at calcium chloride (CaCl2) concentrations of 01 and 03 M, resulting in specimens with average calcium carbonate (CaCO3) content ranging from 15 to 25% for the 50/70 (PDF) Methods for Calcium Carbonate Content 2024年5月6日 The global market for Calcium Carbonate estimated at US$232 Billion in the year 2022, is projected to reach a revised size of US$362 Billion by 2030, growing at a CAGR of 57% over the period 20222030Global Calcium Carbonate Market Analysis –Trends, The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY

.jpg)

Scaling of calcium carbonate (CaCO3) in pipes: Effect of flow

Calcium carbonate scale usually precipitates and grows on industrial equipment such as piping system, causing blockages in the pipes, thus reducing mass and heat transfer This paper presents experimental results of calcium carbonate scale formation in a piping system The scaleforming solution was prepared by mixing equimolar solutions of CaCl2The term "scale" is used to describe a hardened mineral buildup on surfaces, equipment and pipes of a water system Unfortunately, most definitions online refer only to calcium carbonate scale, also known as limescale As we will discuss later in this article, there are several other forms of scale that are not carbonate scale Here's our own definition of scale:Understanding Calcium Carbonate Scale Orenda Tech2016年4月23日 The formation of mineral scale is a complex problem during the oilfield operations Scale inhibitors are widely used to prevent salt precipitation within reservoirs, in downhole equipment, and in production facilities The scale inhibitors not only must have high effectiveness to prevent scale formation, but also have good adsorption–desorption Laboratory investigation of a new scale inhibitor for preventing Keywords: Nucleation; Induction period; Calcium carbonate; Scale 1 Introduction Calcium carbonate is, together with calcium sulphates, the main component of scales on process equipment surfaces Their presence is mostly unwanted in several industrial applications, since scales reduce heat and mass transfer coefficientsCalcium carbonate scales on process equipment: A measure of

.jpg)

Abrasive Blasting Media – Calcium Carbonate – IBIX: Advanced

Abrasive Blasting Media – Calcium CarbonateLaboratory and worksite testing proved Carbonate to be one of the most effective and least invasive materials for cleaning stone, brick, marble and virtually any delicate surface Recommended by the US Capital for Bronze statue cleaning CarbonArt® is available in Grain Sizes Z5 Z6IBIX Calcium CarbonateCategorized as a Carmeuse is a leading producer of ground calcium carbonate Calcium carbonate (CaCO3) is a very common chemical compound making up 4% of the earth’s crust and is the primary constituent in limestone While it is abundant, not all limestone is suitable for ground calcium carbonate (GCC) production due to impuritiesGround Calcium Carbonate Carmeuse2017年1月1日 Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other industries In the present paper, Precipitated Calcium carbonate production, synthesis and propertiesIBIX Calcium Carbonate Categorized as a SOFT abrasive; Specially formulated does not contain salts Great for restoration of soft stone and marble surfaces Great for DeScaling fountains Safe for use around pools and landscaping plantings Two Available Grain/Grit Sizes Z5 6 microns =course; Z6 3 microns =mediumAbrasive Blasting Media – Calcium Carbonate – IBIX: Advanced

.jpg)

Calcium Carbonate Scale Formation in Pipes: Effect

2014年12月31日 Calcium carbonate scale inhibition by three inhibitors, polyacrylic acid (PAA), aminotrimethylenephosphonic acid (ATMP) and polyamino polyether methylenephosphonate (PAPEMP), has been investigated The process of precipitation of calcium carbonate occurs in three stages In the first step, calcium ions combine with carbonate ions to form calcium carbonate (CaCO 3) microparticles Next, CaCO 3 particles combine in microcrystals that serve as crystallization centers for the remainder of the solution Crystal aggregates grow andLaboratory investigation of a new scale inhibitor for preventing 2023年11月14日 Calcium carbonate supplements are an effective way to increase your calcium intake if your diet isn’t sufficient, or you have a condition that leads to lower calcium levels Learn about Calcium Carbonate: Uses, Dosage, and Potential Side EffectsThe Calcium Carbonate Content Chamber, also known as a Rapid Carbonate Analyzer, determines the presence and amount of calcium carbonate (CaCO 3) in soil specimensThis simple and fast test is used as an index to the presence and amount of calcium carbonate in marine soil samples extracted as the percent calcite equivalentCalcium Carbonate Content, Rapid Carbonate Analyzer Karol

.jpg)

Heavy calcium carbonate grinding, surface modification

2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, Heavy calcium carbonate production process and equipment Taking heavy calcium carbonate for coating industry as an example, its production process mainly includes: cleaning and impurity removal, coarse crushing, The calcimeter measures the amount of calcium carbonate, or lime contents, in the soil This is an important indication of the quality of the soil Measure the carbonate content of a soil sample with the Royal Eijkelkamp calcimeter, created for the simultaneous research of 5 samples according to NENISO 10693Carbonate content calcimeter Royal Eijkelkamp2021年12月6日 Based on recent literary sources, this survey discusses the effects of main factors influencing the microbialinduced calcium carbonate precipitation (MICP), including the bacterial species (PDF) MicrobialInduced Carbonate Precipitation: A Review on Highquality thermosensitive products like calcium carbonate require gamechanging solutions WaveMix's lowtemperature microwave drying under vacuum is smart redefined when it comes to processing this essential and highly versatile material Want more information on microwave heating and drying equipment? Visit our WaveMix™ Product PageCalcium Carbonate Drying Equipment Marion Process Solutions

How Calcium Carbonate is Produced?|Manufacturing|CORE

Figure 1 Colloidal calcium carbonate with various particle sizes Surface Treatment in Nanoscale Treating the particle surface of calcium carbonate with various chemicals such as fatty acids and resin acids improves affinity with the matrix and achieves an even higher level of physical properties of the resulted composite materialsIn terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, How to Choose a Calcium Carbonate Grinding MillThe calcium carbonate content indicates the soil's acidity (pH) This determines in large part the quality of the soil, No very accurate weighing equipment needed; Less vulnerable glass parts; It is easier to determine the content using the volumetric method than by weighing the gas;Soil carbonate content measurements Eijkelkamp North America2023年9月27日 Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine mill These grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical grinding equipment for calcium carbonate process CM

(PDF) Development of Calcium CarbonateBased Coatings by the

2022年7月22日 A calcium carbonate (CaCO3)based coating with gammaC2S (γC2S) as the main carbonatable binder is proposed to protect the metal substrate against corrosion in this paperChina Calcium Carbonate Milling Line catalog of High Quality NanoCalcium Grinding Mill Pulverizer, Factory Sell Directly Calcium Carbonate Grinder Pulverizer provided by China manufacturer Zhejiang LEAP Pulverization Equipment Co, Ltd, page1Calcium Carbonate Milling Line Zhejiang LEAP Pulverization Equipment 2024年8月23日 Among them, the dry process is generally used to produce heavy calcium carbonate products with d97≥35μm The main crushing equipment includes Raymond mill, impact mill, dry stirred mill, air flow mill, vertical mill, roller mill, vibration mill and ball millHeavy calcium carbonate dry production process and equipment 2024年4月30日 APEX, established in Taiwan in 1974, specializes in the production of calcium carbonate and masterbatch We obtained ISO9001 international quality certification in 2006 In 2018, APEXVN Co, Ltd was founded in Pingyang, Vietnam, covering an area of 30,000 square meters with a monthly production capacity of 40,000 square meters Our company specializes APEX Calcium Carbonate, Masterbatch, PVC Masterbatch

Calcium Carbonate SNG Microns Pvt Ltd

Calcium carbonate, or CaCO3, comprises more than 4% of the earth’s crust and is found throughout the world Its most common natural forms are chalk, limestone, and marble Calcium carbonate appears as white, odourless powder or colourless crystals Calcium carbonate (CaCO3) is the most widely used filler in polymer formulations As a filler, calcium carbonate []Discover the state of the art of producing high quality Ground Calcium Carbonate (GCC) with Hosokawa Alpine's machinery and technologies Discover the state of the art of producing high quality Ground Calcium Carbonate These demanding requirements are already met worldwide with Hosokawa Alpine equipmentCalcium Carbonate (GCC) Hosokawa Micron Malaysiacalcium carbonate, calcium bicarbonate must react to form calcium carbonate Once attached to the surface, the scale must be strong enough to withstand erosion and the scale will be subjected to ageing which can increase its strength by recrystallization and dehydration 11 Factors effecting scale formationCalcium carbonate scale formation and control Springer2017年11月1日 Tests were also performed at calcium chloride (CaCl2) concentrations of 01 and 03 M, resulting in specimens with average calcium carbonate (CaCO3) content ranging from 15 to 25% for the 50/70 (PDF) Methods for Calcium Carbonate Content

.jpg)

Global Calcium Carbonate Market Analysis –Trends,

2024年5月6日 The global market for Calcium Carbonate estimated at US$232 Billion in the year 2022, is projected to reach a revised size of US$362 Billion by 2030, growing at a CAGR of 57% over the period 20222030The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERYCalcium carbonate scale usually precipitates and grows on industrial equipment such as piping system, causing blockages in the pipes, thus reducing mass and heat transfer This paper presents experimental results of calcium carbonate scale formation in a piping system The scaleforming solution was prepared by mixing equimolar solutions of CaCl2Scaling of calcium carbonate (CaCO3) in pipes: Effect of flow The term "scale" is used to describe a hardened mineral buildup on surfaces, equipment and pipes of a water system Unfortunately, most definitions online refer only to calcium carbonate scale, also known as limescale As we will discuss later in this article, there are several other forms of scale that are not carbonate scale Here's our own definition of scale:Understanding Calcium Carbonate Scale Orenda Tech

.jpg)

Laboratory investigation of a new scale inhibitor for preventing

2016年4月23日 The formation of mineral scale is a complex problem during the oilfield operations Scale inhibitors are widely used to prevent salt precipitation within reservoirs, in downhole equipment, and in production facilities The scale inhibitors not only must have high effectiveness to prevent scale formation, but also have good adsorption–desorption Keywords: Nucleation; Induction period; Calcium carbonate; Scale 1 Introduction Calcium carbonate is, together with calcium sulphates, the main component of scales on process equipment surfaces Their presence is mostly unwanted in several industrial applications, since scales reduce heat and mass transfer coefficientsCalcium carbonate scales on process equipment: A measure of Abrasive Blasting Media – Calcium CarbonateLaboratory and worksite testing proved Carbonate to be one of the most effective and least invasive materials for cleaning stone, brick, marble and virtually any delicate surface Recommended by the US Capital for Bronze statue cleaning CarbonArt® is available in Grain Sizes Z5 Z6IBIX Calcium CarbonateCategorized as a Abrasive Blasting Media – Calcium Carbonate – IBIX: Advanced Carmeuse is a leading producer of ground calcium carbonate Calcium carbonate (CaCO3) is a very common chemical compound making up 4% of the earth’s crust and is the primary constituent in limestone While it is abundant, not all limestone is suitable for ground calcium carbonate (GCC) production due to impuritiesGround Calcium Carbonate Carmeuse

.jpg)

Precipitated Calcium carbonate production, synthesis and properties

2017年1月1日 Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other industries In the present paper,