Superfine mineral powder processing equipment feeder principle circuit diagram

.jpg)

Mineral Processing Plant Design University of Technology, Iraq

crushers to SAG circuits, on both greenfield and retrofit projects, to increase feed rate to the SAG mill In other words, crushing plants, from primary to quaternary circuits, are here to stay 2018年1月5日 HLMX Superfine Vertical Mill is largescale nonmetal mineral superfine powder mill developed by Hongcheng based on HLM Vertical Mill and introduction of foreign advanced Superfine Vertical Mill, superfine powder largescale producing2022年4月7日 To design a robust feeding process and optimise the feeding performance, it is essential to understand feeder design and the underlying relationships between the material Continuous Powder Feeding: Equipment Design and Material 2007年10月24日 A number of factors influence the choice of equipment, including the enduse of the product, required product size distribution, sensitivity of the material to heat, and purity Superfine and Ultrafine Grinding— A Literature Survey: Mineral

.jpg)

7 basic process flows of ultrafine grinding ALPA Powder Equipment

2023年9月13日 The ultrafine grinding unit operation (ie onestage ultrafine grinding) currently used in industry has the following process flows: Opening process Generally, airflow mills 2012年4月1日 The optimum processing conditions of superfine grinding were: feeding pressure of 085 MPa, grinding pressure of 10 MPa, feeding rate of 00325 g/s, feeding particle size of Production of silver carp bone powder using superfine grinding 2015年7月21日 This article discusses the range of application of ultrafine grinding for processing mineral raw materials and presents examples of the successful use of this technology in the Ultrafine Grinding in Contemporary Flow Diagrams for Mineral PowderProcess is a free online handbook giving explanations, design methods and operational tips on the most common unit operations and equipment found in Industries powderprocess Engineering resources for powder

Multiphysics design and analysis of an impellertype superfine

In this paper, a new application field of HSPMM is reported: superfine grinding technology Superfine grinding technology is a new and developing method for preparation of micron, sub 2021年5月11日 The modernday coal processing plants can be categorized into four different circuits, depending upon the size of the coal particles to be treated: (a) coarse coal processing circuit treating particles coarser than 10 mm, (b) small coal circuit for washing particles in the size range of 110 mm, (c) fine coal circuit for cleaning particles in size range of 015–1 mm, and Mineral Beneficiation and Processing of Coal SpringerLinksubsequent operations will be termed as Ore Dressing or Mineral Beneficiation So mineral dressing or ore dressing is commonly regarded as processing of raw ores to yield marketable products by such physical means those do not destroy the physical and chemical identity of the ore Economic Justification of Mineral Dressing: 1LECTURE NOTES ON Mineral Processing (3rd Semester Canada's Largest Supplier of Mineral Processing Equipment About Us; Careers; 18009905568 for on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral Introduction to Mineral Processing or Beneficiation

Vibrating Feeder JXSC Machinery

The vibrating feeder is an electromechanical type of equipment, in which the vibration of the chute is used to transfer the materials from the hopper, silo and silo to the next row of equipment such as crushers, sieving machines, conveyors, etc in a controlled manner The vibrating feeder is used to feed in a controlled manner Not only can they be fed from the hopper, but vibrating 2022年9月30日 Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high separation efficiencyDry Permanent Magnetic Separator: Present Status and Future 2023年8月29日 Superfine grinding is a cuttingedge food powder processing technology that produces particle sizes as small as the nanolevel, resulting in products with exceptional characteristics(PDF) Potentials of superfine grinding in quality modification of 2024年2月18日 For instance, a standard jaw crusher diagram might show a feed rate of 500 tons per hour, translating to processing massive volumes like 1200 cubic meters of limestone or iron ore in a single day—a testament to the machine’s indispensable role in Jaw Crusher Diagram: Simplified Guide JXSC

Principles of Mineral Processing Google Books

Destined to become an industry standard, this comprehensive reference examines all aspects of minerals processing, from the handling of raw materials to separation strategies to the remediation of waste products The book incorporates stateoftheart developments in the fields of engineering, chemistry, computer science, and environmental science and explains how As an endtoend provider, Superfine Minerals manage your talcum powder supply holistically with the aim of generating more efficiency, profitability and transparency We achieve this through our indepth expert knowhow and our global network, through our own processing and manufacturing plants as well as through our strong supply chainHOME Superfine Minerals2024年1月17日 For nonmetallic mineral grinding, the choice of processing equipment is very important Different types of grinding equipment are suitable for minerals of different attributes, and have specific correspondences to hardness, raw material size, humidity, output, etc, and understanding the working principle, performance characteristics and scope of application of 11 types of grinding equipment commonly used in the nonThe primary function of the disc feeder is to supply materials to other equipment The material can evenly enter a device so that the following process can work normally The disc feeder comprises a driving device, a feeder body, a belt conveyor for metering, and a metering device It is a feeding device suitable for fine ore below 20mmDisc Feeder JXSC

.jpg)

PRODUCTS

2019年7月1日 Weifang Jinghua Powder Engineering Equipment Co, ltd Established in 1996, it is working on research and development of powder engineering equipments and technology, and it has become one of main 2014年5月15日 Mineral Processing Download as a PDF or view Superfine grinding 10 microns 1 micron STEPS IN COMMINUTION Size reduction/Comminution Process : extremely energyintensive 5 % of all Mineral Processing PPT SlideShare2021年11月3日 Phosphate mineral powder grinding mills are processing equipment for phosphate rock powders Choosing a highefficiency, intelligent, energysaving, and environmentally friendly phosphate rock powder mill can greatly enhance the market competitiveness of phosphate rock powders and create more great valuePhosphate Mineral Powder Grinding Mill SBM Ultrafine Powder 2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911Metallurgist

Comminution a Heart of Mineral Processing ResearchGate

2021年7月6日 Figure 4 (a) Open Circuit Diagram and (b) Choke Feeding Circuits 454 Closed Circuit Grinding: Another mode of operation is closed circuit grinding as depicted in Figure 4 (c)2017年8月24日 Haldar described mineral processing «as the valueadded processing of raw material (runofmine ore) to yield marketable intermediate products (eg copper concentrate) or finished products (eg silica sand) containing more than one valuable minerals and separation of gangue (tailing)»The runofmine components consist of the following:Mineral Processing SpringerLink2016年10月12日 This type of grinding is the most common circuit found in mineral processing facilities, Although closed circuit grinding offers many choices for arrangement of the equipment as well as combinations of equipment, some of the more common circuits are rod mill/classifier, Ball mill/Classifier, Rod mill/Ball mill/Classifier and Rod Closed Circuit Grinding VS Open Circuit Grindingcement manufacturing process by tizita moges , selamu abule dereje endalamaw if you need this guide and all other useful excel sheets which will make you master the production , process , maintenance activity in your cement plant kindly click hereCement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

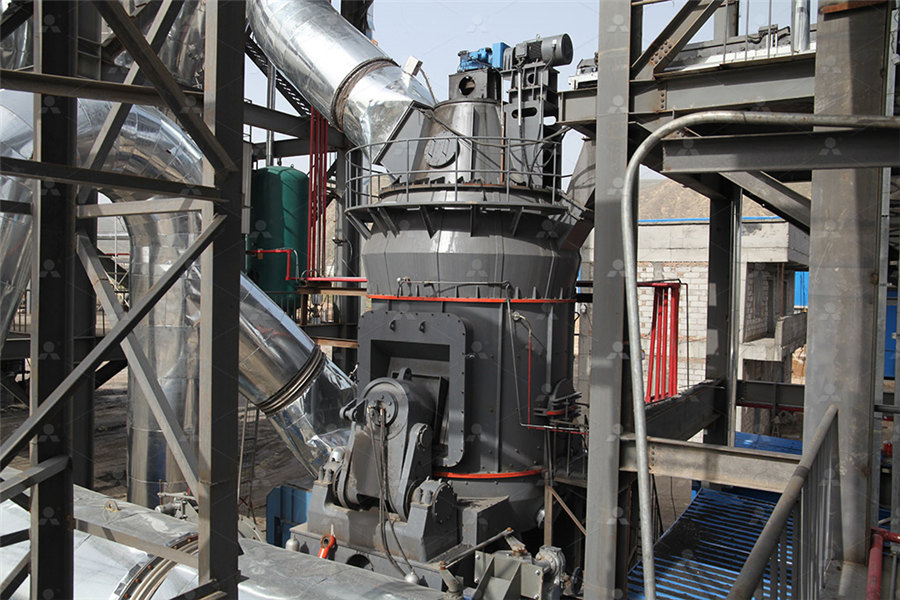

Superfine Vertical Mill, superfine powder largescale producing

2018年1月5日 7 HLMX Vertical Mill—(80600 mesh) Powder Processing The traditional ultrafine powderprocessing equipment, due to its low production capacity, is unable to meet the requirements of largescale production to satisfy the increasing great market demand Combining several decades of powder mill RD and production experience and by introducing advanced 2020年12月3日 This study is conducted with the aim of investigating the efficiency of open and closedcircuit molybdenite ore comminution processes (primary and secondary mill, respectively), through A process mineralogy approach to study the efficiency of 2015年8月3日 PDF The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a Find, read and cite all the research you (PDF) Overview of Mineral Processing MethodsEconomical and practical ultrafine powder processing equipment HM ultrafine ring roller mill is a new type of ultrafine power processing equipment The product powder fineness can be adjusted between 325 mesh and 2500 mesh according to the needs, fineness can reach D97≤5umHM Superfine Ring Roller Mill Grinding Mill Fertilizer

Powder Feeders Metal Tech

The PFD401 Series is a rotating disk feeder conceived to feed various types of fee flowing powder at constant feed rate The PFD401 can be used for a powder size range from 10pm up to 300pm Our Ultrasonic vibration device which is standard on all Tekna Powder Feeders provides the advantage of pasting powder feeding without problems2016年10月18日 Since several types of flotation circuits can generally be employed in conjunction with the various processes for the flotation of different classes of minerals, an outline of the standard circuits in common use is best given before the processes to which they are applicable are described The flow sheets illustrating them are diagrammatic, but, in cases Flotation Circuits Diagrams 911Metallurgist2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment Mineral Processing181 Process Flow Diagram (PFD) Symbols for Engineers Welcome to our process flow diagram symbols list Scroll down and use the table of contents on the left to navigate this page and see the different symbol types most commonly used by engineersBut first, let’s review the purpose and benefits of181 Process Flow Diagram (PFD) Symbols for Engineers

.jpg)

Mineral Processing Pilot Plant Equipment 911Metallurgist

2016年6月10日 The testing of tonnage lots of ores and industrial materials by continuous Mineral Processing Pilot Plant operation is in many instances advisable before a full scale milling plant is installed The treatment of complex ores by new processes or by the use of new or unusual reagents in flotation may involve problems the effect of which should be studied under 2024年5月9日 Magnetic separation technology plays a pivotal role in mineral processing, offering efficient and versatile solutions for separating valuable minerals from gangue materials By harnessing the magnetic properties of minerals, magnetic separators can selectively capture and concentrate target minerals based on their magnetic susceptibility, facilitating highpurity Mining Mineral Processing Southern AfricaDownload scientific diagram Principle of the microfeeder system from publication: Performance Evaluation of a HighPrecision LowDose Powder Feeder Highly potent active pharmaceutical Principle of the microfeeder system Download Scientific Diagram2021年5月11日 The modernday coal processing plants can be categorized into four different circuits, depending upon the size of the coal particles to be treated: (a) coarse coal processing circuit treating particles coarser than 10 mm, (b) small coal circuit for washing particles in the size range of 110 mm, (c) fine coal circuit for cleaning particles in size range of 015–1 mm, and Mineral Beneficiation and Processing of Coal SpringerLink

36.jpg)

LECTURE NOTES ON Mineral Processing (3rd Semester

subsequent operations will be termed as Ore Dressing or Mineral Beneficiation So mineral dressing or ore dressing is commonly regarded as processing of raw ores to yield marketable products by such physical means those do not destroy the physical and chemical identity of the ore Economic Justification of Mineral Dressing: 1Canada's Largest Supplier of Mineral Processing Equipment About Us; Careers; 18009905568 for on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral Introduction to Mineral Processing or BeneficiationThe vibrating feeder is an electromechanical type of equipment, in which the vibration of the chute is used to transfer the materials from the hopper, silo and silo to the next row of equipment such as crushers, sieving machines, conveyors, etc in a controlled manner The vibrating feeder is used to feed in a controlled manner Not only can they be fed from the hopper, but vibrating Vibrating Feeder JXSC Machinery2022年9月30日 Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high separation efficiencyDry Permanent Magnetic Separator: Present Status and Future

.jpg)

(PDF) Potentials of superfine grinding in quality modification of

2023年8月29日 Superfine grinding is a cuttingedge food powder processing technology that produces particle sizes as small as the nanolevel, resulting in products with exceptional characteristics2024年2月18日 For instance, a standard jaw crusher diagram might show a feed rate of 500 tons per hour, translating to processing massive volumes like 1200 cubic meters of limestone or iron ore in a single day—a testament to the machine’s indispensable role in Jaw Crusher Diagram: Simplified Guide JXSCDestined to become an industry standard, this comprehensive reference examines all aspects of minerals processing, from the handling of raw materials to separation strategies to the remediation of waste products The book incorporates stateoftheart developments in the fields of engineering, chemistry, computer science, and environmental science and explains how Principles of Mineral Processing Google BooksAs an endtoend provider, Superfine Minerals manage your talcum powder supply holistically with the aim of generating more efficiency, profitability and transparency We achieve this through our indepth expert knowhow and our global network, through our own processing and manufacturing plants as well as through our strong supply chainHOME Superfine Minerals

11 types of grinding equipment commonly used in the non

2024年1月17日 For nonmetallic mineral grinding, the choice of processing equipment is very important Different types of grinding equipment are suitable for minerals of different attributes, and have specific correspondences to hardness, raw material size, humidity, output, etc, and understanding the working principle, performance characteristics and scope of application of