Silica ore mill hourly output

Effect of ball and feed particle size distribution on the milling

2018年6月1日 In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size distribution were investigated Silica ore was used as the test materialSilica Silica minerals in bauxite are mainly kaolin and quartz Kaolin is highly reactive, while quartz requires more severe conditions to dissolve Under standard digestion conditions all Chemical Processing of Bauxite: Alumina and Silica Ore was loaded into a hopper and fed with a belt conveyor at approximately 300 pounds per hour to a pulper where water was added and the pulp agitated for five minutes The material was PILOT PLANT PROCESSING OF SILICA ORE P2 InfoHouseBasic parameters of 69 jaw silica ore crusher (PE600×900): [Feed size]: ≤480mm [Outlet size]: 65160mm [Processing capacity]: 90180t/h [Motor power]: 5575kw [Weight]: 17t Therefore, How much material does the 69 jaw silica ore crusher discharge

(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals

2022年1月23日 Beside the processing behaviour of the main constituents of bauxite such as hydrated alumina and silica minerals, the Chapter covers the impact of other constituents, 2018年2月1日 In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle sizeEffect of ball and feed particle size distribution on the milling Foundry silica sand is the quartz as the main mineral composition, particle size of 0020 mm to 3350 mm refractory particles, according to the mining and processing methods of different Silica Mining Processing Equipment Flow Chart Cases JXSCThis vertical mill produced by Guilin Hongcheng is an ideal choice for silica mill The silica can be ground to 80600 mesh, and the output can reach 1200 tons per hour High output, uniform Silica Grinding Mill

.jpg)

Use of the attainable region approach to determine major trends

2016年4月1日 In this paper, we will present the results for experiments done on two different types of material, namely silica ore and gold ore The ball loading (J) milling parameter is 2016年3月21日 From these samples the essential information is derived by means of analyses for metal content, particle size distribution, and content of water or other ingredient in the ore Common Basic Formulas for Mineral Processing Calculations2023年8月10日 Silica sand processing manufacturer Silica sand is a versatile material with a wide range of applications due to its unique properties After crushing, scrubbing, magnetic separation, and flotation, the purity of silica Silica Processing Plant 4 Major Stages to Make Silica In Fig 41, the numbers 150200250 on the graphs of equilibrium relate to caustic soda concentrations in Na 2 CO 3A/C denotes aluminate ion concentration as Al 2 O 3 (A)/caustic soda concentration as Na 2 CO 3 (C) A typical Bayer process cycle with low temperature digestion is also shown Virtually each bauxite contains more or less amount of clay minerals, Chemical Processing of Bauxite: Alumina and Silica

CFB石灰石脱硫剂制备64.jpg)

Common Basic Formulas for Mineral Processing

2016年3月21日 where R represents the ratio: % Pb in crude ore/% Cu in crude ore Formula (32) is very convenient for milling calculations on ores of this type Example: An ore contains 5% lead and 1% copper The ratio of perfect 2020年4月12日 The extraction behavior of zirconium(IV) from succinate (001 – 003 M) medium (25 mL) with 10 mL 3 % Nnoctylaniline in xylene was investigatedExtraction of Zirconium, Uranium, Hafnium and Silica Gel from Silica Sand Plant Mineral Ore Ball Mill Grinding For Gold Ore Mining, You can get more details about Silica Sand Plant Mineral Ore Ball Mill Grinding For Gold Ore Mining from mobile site on Alibaba Ore Ball Mill 1200*2400 High Output Grinding Ore Ceramic Diesel Engine Ball Mill Machine Mining Cip Equipment $3,50000 Min order: 1 setSilica Sand Plant Mineral Ore Ball Mill Grinding For Gold Ore After desliming of rod mill output by means of screw classifiers, the product of this stage is delivered to eight trommel screens The coarse particles (+800µm) are recycled to wet rod mill for Improvement in product of silica plant by modification of size

News How much is the silica grinding mill for 1020 tons of silica

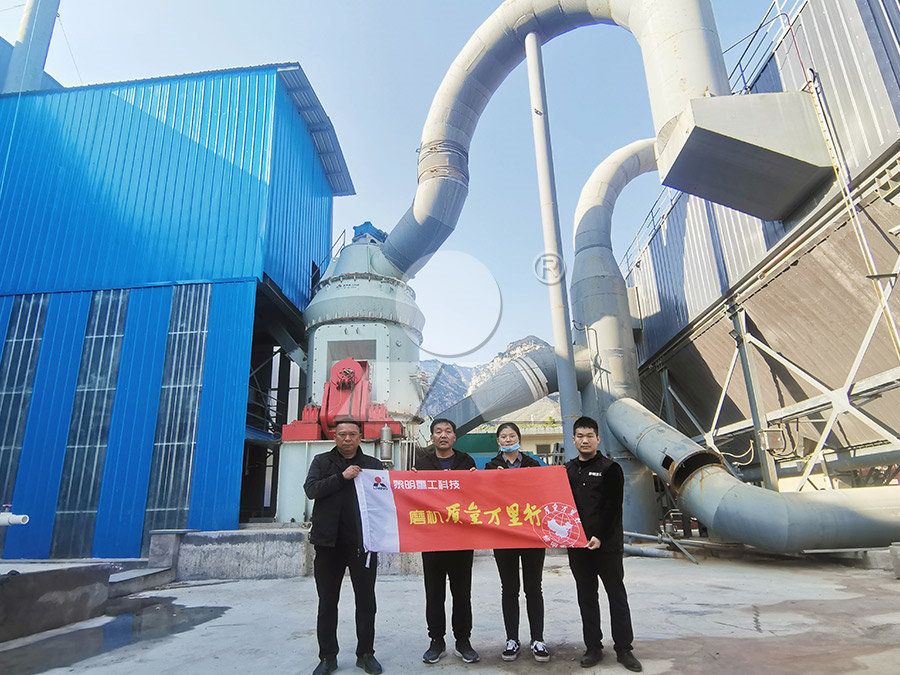

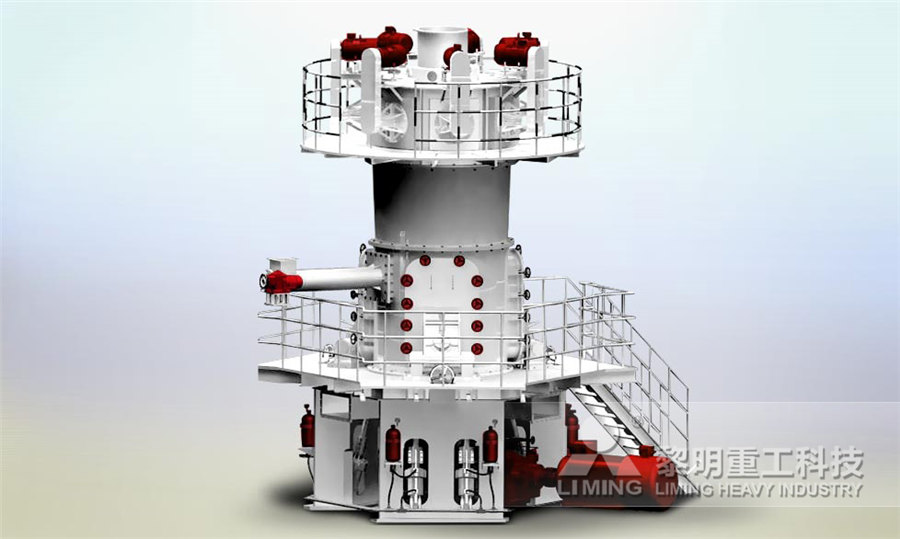

The rise of the powder industry has made many ores into powder, and its economic value has been improved Silica is a valuable ore in the economic field After it is processed into silica powder, its application field is wider The processing and preparation of silica powder is inseparable from the output of complete sets of silica powder grinding equipment2019年7月12日 Silicon fertilizer has been prepared by converting crystalline silica from ore into plantavailable silicon using a roasting method The results of roasting experiments showed that adding limestone as an additive ingredient and sodium hydroxide as a roasting fluxing agent significantly increased the conversion rate of plantavailable silicon Both the roasting An Efficient and Sustainable Approach for Preparing Silicon Fertilizer 2023年6月23日 Indian staterun steel producer Steel Authority of India Limited (SAIL) has operationalized a silica reduction plant at the DalliRajhara cluster of iron ore mines linked to its Bhilai Steel Plant (BSP), a company official said on Friday, June 23 He said that the silica reduction plant has been installed at investment of $18 million and is needed to improve the SAIL installs silica reduction plant at captive iron ore SteelOrbis2021年11月8日 Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including ultrafine mill, activated alumina, and activated silica fume In addition, because of its small particle size, large Illite Ore Industrial Grinding Mill Machine SBM

.jpg)

Ball Mill Ball Grinding Mill SKE

You can apply our ball mill in ore beneficiation plant to grind iron ore, copper ore, gold ore, lead ore, zinc ore, kaolin, bentonite, feldspar, silica, etc Grid Type Ball Mill The Grid Type Ball Mill has high discharge speed and high productivity sible to shorten the time of iron ore inside a ball mill, the ball mill output grows as a result, and a larger size product is obtained The grain size required for pelletizing is reached in further HPGR grinding (Fig 5) In so doing, energy consumed by milling, ball mill wear and power taken by filters are reducedHIGH PRESSURE GRINDING ROLLS—A PROMISING AND COST 2017年6月23日 "We used to be able to procure ores with silica content of around 65%, but now we can only take in ores of less than 52%," a Hebeibased mill source added This contrasts to 2014 and 2015 when mills struggled to make margins and domestic concentrates were in short supply due to uncompetitiveness, and the silica penalty was negligibleAnalysis: Iron ore impurities penalties surge on SP Global2020年7月15日 The grinding media are lifted up with the rotation of the mill, and then dropped down onto the ore particles low energy consumption, and low noise It is widely used in the production of quartz sand, silica sand, Improving Efficiency and Output with Quartz Ball Mill Classification Production Line Company News / A Comprehensive Guide to Understanding Quartz Ball Mill

Ore mill, Ore grinding mill All industrial manufacturers

Ore mill Ore mills 21 companies 42 products My filters for ore Delete all Manufacturers C; Ceramic Instruments Srl (2) D; Output: 16 t/h 50 t/h Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefication, 2021年3月22日 Assessing Machine learningbased approaches for Silica concentration estimation in Iron Froth flotationAssessing Machine learningbased approaches for Silica Sallies Silica mines, manufactures and distributes quality silica sand Consistent quality across a wide range of grades, product availability, practical packaging, product handling, and ontime delivery – these are the key factors that form the core of our serviceSallies Silica2024年11月4日 The main raw material of silicon powder is silica (SiO2), which is a finer silica powderSilicon powder, also known as silica ash or microsilicon powder, is widely used in many fieldsWe know that a ball mill is a generalpurpose grinding equipment that can handle many materials, but the advantages of grinding fineness are not significant, so can we use a ball mill Can a ball mill grind silica?

92 questions with answers in IRON ORE Science topic

2015年2月25日 Review and cite IRON ORE protocol, troubleshooting and other methodology information Contact experts in IRON ORE to get answers2024年11月21日 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the overcrushing of ore, and at the same time it can increase the output per unit volume 1 Large row of ore mouth Ball Mill Is Indispensable For Lithium Ore Processingsible to shorten the time of iron ore inside a ball mill, the ball mill output grows as a result, and a larger size product is obtained The grain size required for pelletizing is reached in further HPGR grinding (Fig 5) In so doing, energy consumed by milling, ball mill wear and power taken by filters are reducedHIGH PRESSURE GRINDING ROLLS—A PROMISING AND COST For the purposes of this example, we will hypothesize that the the crushing index of the hard ore with the increased energy input of 154 kw/t reduces the ball mill feed size to 6,500 micrometers As a result, the mill output will increase with this reduced size to ball mill size for silica flotation cell ore russian in Oman

Quality Prediction in a Mining Process Using Machine Learning

2020年6月6日 The notebook approaches on the prediction of silica in minute The approach used different regression models and used R^2 as metric and obtained results based up on the trained models The spiral chute produces three outputs: concentrate, medium ore and tailings Middling may still contain some silica sand The concentrate from the firststage spiral chute is sent to the concentrate chute, and the medium ore enters the secondstage spiral chute through the sand pump for reprocessing 5Silica Sand Processing Plant JXSC MachineryThe rise of the powder industry has made many ores into powder, and its economic value has been improved Silica is a valuable ore in the economic field After it is processed into silica powder, its application field is wider The processing and preparation of silica powder is inseparable from the output of complete sets of silica powder grinding equipmentNews How much is the silica grinding mill for 1020 tons of silica Energy Saving Factory Price Wet Ball Mill Gold Ore Grinder Silica Sand Grinding Ball Mill Ball Mill For Sale In Zimbabwe $4,90000 $5,50000 Min Order: 1 set 7 yrs CN Supplier 50 /5 8 reviews "good service" Contact Supplier Chat now wet and dry grinding mill mineral stone vibrating ball mill for silica sand $5,50000 $6,00000Simple Ore Extraction: Choose A Wholesale silica sand ball mill

On the Mechanisms of Silica (SiO2) Recovery in Magnetite Ore

2018年12月10日 Magnetite (Fe3O4) ore is concentrated by lowmagneticfield drums to recover a magnetite concentrate that is low in silica (SiO2) The presence of SiO2 in the magnetite concentrate for steel production increases the steel processing costs, so a major challenge in magnetic concentration is to lower the SiO2 grade in the Fe concentrate This work presents 2005年1月1日 With the aim of producing a concentrate with silica content lower than 10 per cent SiO2, laboratory experiments were conducted using a sample of the final concentrate from the Samarco iron ore Production of an iron ore superconcentrate from the samarco In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al [50] using the attainable region technique on a silica ore by dry milling, a threeball mix of Size class used to monitor the breakage of silica ore2023年8月10日 Silica sand processing manufacturer Silica sand is a versatile material with a wide range of applications due to its unique properties After crushing, scrubbing, magnetic separation, and flotation, the purity of silica Silica Processing Plant 4 Major Stages to Make Silica

Chemical Processing of Bauxite: Alumina and Silica

In Fig 41, the numbers 150200250 on the graphs of equilibrium relate to caustic soda concentrations in Na 2 CO 3A/C denotes aluminate ion concentration as Al 2 O 3 (A)/caustic soda concentration as Na 2 CO 3 (C) A typical Bayer process cycle with low temperature digestion is also shown Virtually each bauxite contains more or less amount of clay minerals, 2016年3月21日 where R represents the ratio: % Pb in crude ore/% Cu in crude ore Formula (32) is very convenient for milling calculations on ores of this type Example: An ore contains 5% lead and 1% copper The ratio of perfect Common Basic Formulas for Mineral Processing 2020年4月12日 The extraction behavior of zirconium(IV) from succinate (001 – 003 M) medium (25 mL) with 10 mL 3 % Nnoctylaniline in xylene was investigatedExtraction of Zirconium, Uranium, Hafnium and Silica Gel from Silica Sand Plant Mineral Ore Ball Mill Grinding For Gold Ore Mining, You can get more details about Silica Sand Plant Mineral Ore Ball Mill Grinding For Gold Ore Mining from mobile site on Alibaba Ore Ball Mill 1200*2400 High Output Grinding Ore Ceramic Diesel Engine Ball Mill Machine Mining Cip Equipment $3,50000 Min order: 1 setSilica Sand Plant Mineral Ore Ball Mill Grinding For Gold Ore

.jpg)

Improvement in product of silica plant by modification of size

After desliming of rod mill output by means of screw classifiers, the product of this stage is delivered to eight trommel screens The coarse particles (+800µm) are recycled to wet rod mill for The rise of the powder industry has made many ores into powder, and its economic value has been improved Silica is a valuable ore in the economic field After it is processed into silica powder, its application field is wider The processing and preparation of silica powder is inseparable from the output of complete sets of silica powder grinding equipmentNews How much is the silica grinding mill for 1020 tons of silica 2019年7月12日 Silicon fertilizer has been prepared by converting crystalline silica from ore into plantavailable silicon using a roasting method The results of roasting experiments showed that adding limestone as an additive ingredient and sodium hydroxide as a roasting fluxing agent significantly increased the conversion rate of plantavailable silicon Both the roasting An Efficient and Sustainable Approach for Preparing Silicon Fertilizer 2023年6月23日 Indian staterun steel producer Steel Authority of India Limited (SAIL) has operationalized a silica reduction plant at the DalliRajhara cluster of iron ore mines linked to its Bhilai Steel Plant (BSP), a company official said on Friday, June 23 He said that the silica reduction plant has been installed at investment of $18 million and is needed to improve the SAIL installs silica reduction plant at captive iron ore SteelOrbis