3. How much is the capacity of highfine cement mill

.jpg)

Cement Production by Country 2024 World Population Review

Cement isn't typically used on its own but is added to other materials to create a hardened substance In this article, we will take a closer look at which countries are producing the most 2021年12月21日 Nearly 80Mt/yr of new cement capacity will be commissioned in 2022 and the same amount is forecast again for 2023 These figures could be even higher because the lead Global Projects: Cement capacity expansion to 20256 Cement Mill The cement mill grinds the clinker to a fine powder, which is then mixed with gypsum to form cement Equipment: Ball mills, vertical roller mills Technical Specifications: Ball Mills: 1030 tons/hour capacity, 5001500 kW The Comprehensive Guide to Cement Plant Costs: An 2024年11月9日 In 2022, China had the highest cement production capacity in the world by far, at an estimated 164 billion metric tons per year (or more) China's cement production capacity included anCement capacity: global ranking by country 2022

Cement PACRA

• Cement sector’s production capacity is recorded around ~64mln tons in FY20 (~60mln tons in FY19), an increase of ~7% YoY Almost ~76% of the operational plants are located in the 2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, Review on vertical roller mill in cement industry its performance The Med rim has the highest cement capacity both integrated and grinding Eastern subregion has the lowest capacity, but the largest average integrated plant size Central/Western and European cement 年10月13日 Despite this, the cement industry continues to grow, driven by increasing demand for infrastructure development in emerging economies and urbanization in developed Global database of cement production assets and upstream

.jpg)

Cement Mill Cement Ball Mill Vertical Cement Mill

Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement mill AGICO Cement can supply cement mill according to your requirements We also provide the A review of the effectiveness of Life Cycle Assessment for gauging environmental impacts from cement production Oluwafemi E Ige, Collins Obiora, in Journal of Cleaner Production, 2021 223 Production of clinker The clinker production stage is where the raw material (the raw meal) converts into clinker The raw meal is fed into a rotary kiln through a preheater at about 1450 Clinker Production an overview ScienceDirect TopicsThe ball mill price is affected by the following factors, you can choose a suitable cement ball mill according to these factors Cost of production: materials cost, human cost, electricity power cost, etc; Technical costs: technology import, Cement Ball Mill Ball Mill For Sale Cement Mill 15 Aquí nos gustaría mostrarte una descripción, pero el sitio web que estás mirando no lo permiteCapacity of biggest global cement producers 2024

Cement Production Demystified: StepbyStep Process and

3 Energy requirements and CO2 emissions of cement production 31 How much CO2 is emitted per ton of cement produced ? Cement production is an energyintensive process due to the high temperatures required to produce clinker in a kiln but also due to the chemical reactions happening during pyroprocessing2020年1月6日 Figure 3 shows that, should all of the planned capacity additions be realised, the next two years to the end of 2021 could see the addition of a further 77Mt/yr of cement production capacity to 435Mt/yr This is around 21% more than 358Mt/yr at present‘Build, Build, Build’ing in the Philippines Global CementTable 1: Capacity Utilisation by Cement Industry Year Production (Million tonnes) Cement: Capacity Addition (Million tonnes) Cement: Outstanding Capacity (Million tonnes) Cement: Capacity Utilisation (%) 201516 2739 1554 49532 621 201617 2704 2809 52341 584 201718 2880 2142 54483 600 201819 3277 1554 49532 662According to the estimate of the National Council for Cement and Adjusting mill parameters: Finetuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill For example, a 10% increase in mill speed can result in up to 10% higher production rate, while optimizing the ball charge can lead to a 510% reduction in energy consumptionCement Mill Optimization: Practical Strategies for Enhanced

Cement PACRA

cement production capacity which hovers around ~43 bln tons Around ~45% of the global capacity is occupied by the top 10 players China leads with a ~57% share, followed by India (~8%), Vietnam, USA and Indonesia Globally, more than 1,000 cement producers operate over 2,300 integrated cement plants and 600 grinding stations •PDF On Dec 4, 2015, Zuheir M Abdelatif and others published EFFECT OF BLAINE FINENESS OF CEMENT ON RATE OF HEAT AND TOTAL HEAT OF HYDRATION Find, read and cite all the research you need on (PDF) EFFECT OF BLAINE FINENESS OF CEMENT ON RATE OFIn Q3FY21, Ambuja Cement has recorded the highest capacity utilization of 943%, receiving the topmost position Next to it comes ACC Cement and Dalmia Bharat, which have Utilization capacity of 922% and 814%, respectively It is ranked and scored accordingly, because Shree Cement has the lowest capacity utilization of 713%Comparison of Top 5 Cement Companies UltraTech vs Shree vs Another important factor to consider is the overall clinker capacity of a country Clinker refers to the material that is produced before cement is produced It is later added to the mix and serves as the binder of the final product The country that had the most clinker capacity, with 2,000,000 metric tons of it in 2023, was ChinaCement Production by Country 2024 World Population Review

.jpg)

The Ramco Cements Limited Corporate Presentation

3 Shree Cement Limited 4340 8% 4 Dalmia Bharat Limited 3075 6% 5 Nuvoco Vista Corp Limited 2232 4% 6 The Ramco Cements Limited 1940 4% 7 India Cements Limited 1555 3% 8 Birla Corporation Limited 1538 3% 9 Chettinad Cement Limited 1492 3% 10 JSW Cement Limited 1393 3% Total 35275 67%6 Cement Mill The cement mill grinds the clinker to a fine powder, which is then mixed with gypsum to form cement Equipment: Ball mills, vertical roller mills Technical Specifications: Ball Mills: 1030 tons/hour capacity, 5001500 kW The Comprehensive Guide to Cement Plant Costs: An 3 What sand and cement ratios should be used for laying floor screeds? For laying floor screeds, a common recommended ratio is 1 part cement to 35 parts sand The desired finish and the purpose of the screed will influence the exact ratio needed How to Calculate the Correct Sand and Cement Mix Ratios for HIGH STRENGTH MICRO/NANO FINE CEMENT A GarcíaLuna (1), H Minard(1), BR Diego(2) (Capacity Force max= 1300 kN, by Controls) after 1, 3, 7 and 28 days of curing Different tests was been done varying the substitution amount of refined material added to the mixture (mortar)HIGH STRENGTH MICRO/NANO FINE CEMENT

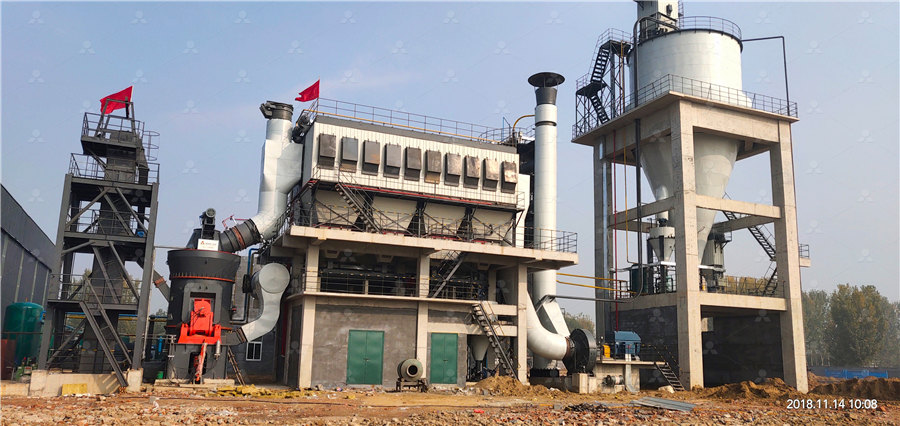

CFB石灰石脱硫剂制备96.jpg)

Clinkerization Cement Plant Optimization

Capacity has increased from as low as 50 tpd to as high as 12000 tpd from kiln Heat consumption reduced from 1400 kcal/kg to 670 kcal/kg of clinker Specific heat consumption of various kiln systems is tabulated (Table 2) below to assess the progress in the development of clinkerization technology2020年1月1日 The demand for cement, which is one of the key components of concrete, is high in Ethiopia, but it is the most expensive and environmentally unfriendly construction materialAssessment on Cement Production Practice and Potential Cement 2020年8月25日 Buoyed by healthy growth outlook, the cement industry is pressing the pedal on capacity additions, with ~80 million tonne (MT) expected over the next three years through fiscal 2024, a quarter more than that seen during the last three fiscals (~64 MT) This will also be the highest capacity addition seen in any block of three consecutive years, during the last 10 year 80 MT cement capacity addition in next 3 years, a ten year highChanging the separator to high efficiency type bringa about better residue value (on 45 s micron) for the same Blaine Alternatively, the cement can be ground to a lower Blaine with the same residue, which determines the strength of cement In most cases the layout permits replacing the separator to a high efficiency typeOPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

.jpg)

Top 10 Cement Companies in India 2023

2023年9月25日 Market Share: 3; From a two plant company having a capacity of just 13 million tonnes in 1989, India Cements has robustly grown in the last two decades to a total capacity of 155 million tonnes per annum It is seventh in the list of top 10 cement company in India Sales: ₹ 5,531 Cr Operating profit: ₹ 175 Cr Net profit: ₹ 294 CrBut however, it can be reactivated by different methods like vibro grinding etc vibro grinding improves fineness quality of long period stored cement and make it fit for the constructional purpose 3 Place of Cement Storage The bags of Storage of Cement – Precautions, Duration and 2024年8月20日 Rapid hardening cement, also known as HighEarly Strength Portland Cement, has a fineness ratio of 3–5% It gains strength faster than OPC, but its final strength is only slightly higher Lowheat cement Has a fineness ratio of 5% It’s similar to Portland cement but has a different chemical composition that generates less heat while settingWhat is the fineness of the cement? BricknBolt2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in EnergyEfficient Technologies in Cement Grinding

An Introduction to Clinker Grinding and Cement Storage

would be a length of 135 m and a diameter of 25 m, with a speed of approximately 20 revolutions per minute Such a mill would normally have a load of approximately 90 tons of grinding media, graduated from 90 mm to 60 mm in the first chamber, 50 mm to 15 mm in the second chamber and 15 mm down in the final chamberStrength of PCC is defined as compressive strength after 28 days, expressed as M15, M20, where M stands for Mix and 15 stands for 15 N/mm 2 (n/mm 2 must be read as 'Newton’s per millimeter Cubic') compressive strength at 28 days The proportions of materials (cement, sand, coarse aggregate) for nominal mix/design mix concrete that are normally used are 1:3:6 or 1:4:8Cement Concrete Calculator PCC Calculator RCC CalculatorSpace needed for vertical mill is much less than a closed circuit ball mill of same capacity As separator is integral part of the mill itself, the number of auxiliary equipments are less Total power consumption for grinding circuit as a whole is also less by about 30% compared to closed circuit ball mill in spite of higher fan powerCement Grinding Cement Plant OptimizationHigh strength concrete grade are M50, M55, M20 grade concrete ratio is nominally about 1:15:3, mixture of cement, fine aggregates and course aggregate in which one part of cement mixed with one parts of sand and two parts of aggregate and How much cement sand aggregate required for M20 concrete

.jpg)

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

For VRM the production capacity denotes both the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill and roller pressure The capacity of the mill is calculated Using G K * D 251 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table diameter 2 PROCESS CONTROL OF VRM2021年7月28日 Cement Mill Vertical Roller Mill: 2707: Cement Mill Ball Mill Closed Circuit: 2320: Cement Mill Ball Mill with HPRG: 065: Packing Plant: 067: Compressor upto clinkerisation: 089: Compressor Cement Griding and PackingIndian Cement Sector CMAPDF On Oct 10, 2018, Hosam M Saleh and others published Introductory Chapter: Properties and Applications of Cement Based Materials Find, read and cite all the research you need on ResearchGate(PDF) Introductory Chapter: Properties and Applications of Cement A review of the effectiveness of Life Cycle Assessment for gauging environmental impacts from cement production Oluwafemi E Ige, Collins Obiora, in Journal of Cleaner Production, 2021 223 Production of clinker The clinker production stage is where the raw material (the raw meal) converts into clinker The raw meal is fed into a rotary kiln through a preheater at about 1450 Clinker Production an overview ScienceDirect Topics

.jpg)

Cement Ball Mill Ball Mill For Sale Cement Mill 15

The ball mill price is affected by the following factors, you can choose a suitable cement ball mill according to these factors Cost of production: materials cost, human cost, electricity power cost, etc; Technical costs: technology import, Aquí nos gustaría mostrarte una descripción, pero el sitio web que estás mirando no lo permiteCapacity of biggest global cement producers 20243 Energy requirements and CO2 emissions of cement production 31 How much CO2 is emitted per ton of cement produced ? Cement production is an energyintensive process due to the high temperatures required to produce clinker in a kiln but also due to the chemical reactions happening during pyroprocessingCement Production Demystified: StepbyStep Process and 2020年1月6日 Figure 3 shows that, should all of the planned capacity additions be realised, the next two years to the end of 2021 could see the addition of a further 77Mt/yr of cement production capacity to 435Mt/yr This is around 21% more than 358Mt/yr at present‘Build, Build, Build’ing in the Philippines Global Cement

36.jpg)

According to the estimate of the National Council for Cement and

Table 1: Capacity Utilisation by Cement Industry Year Production (Million tonnes) Cement: Capacity Addition (Million tonnes) Cement: Outstanding Capacity (Million tonnes) Cement: Capacity Utilisation (%) 201516 2739 1554 49532 621 201617 2704 2809 52341 584 201718 2880 2142 54483 600 201819 3277 1554 49532 662Adjusting mill parameters: Finetuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill For example, a 10% increase in mill speed can result in up to 10% higher production rate, while optimizing the ball charge can lead to a 510% reduction in energy consumptionCement Mill Optimization: Practical Strategies for Enhanced cement production capacity which hovers around ~43 bln tons Around ~45% of the global capacity is occupied by the top 10 players China leads with a ~57% share, followed by India (~8%), Vietnam, USA and Indonesia Globally, more than 1,000 cement producers operate over 2,300 integrated cement plants and 600 grinding stations •Cement PACRAPDF On Dec 4, 2015, Zuheir M Abdelatif and others published EFFECT OF BLAINE FINENESS OF CEMENT ON RATE OF HEAT AND TOTAL HEAT OF HYDRATION Find, read and cite all the research you need on (PDF) EFFECT OF BLAINE FINENESS OF CEMENT ON RATE OF

.jpg)

Comparison of Top 5 Cement Companies UltraTech vs Shree vs

In Q3FY21, Ambuja Cement has recorded the highest capacity utilization of 943%, receiving the topmost position Next to it comes ACC Cement and Dalmia Bharat, which have Utilization capacity of 922% and 814%, respectively It is ranked and scored accordingly, because Shree Cement has the lowest capacity utilization of 713%