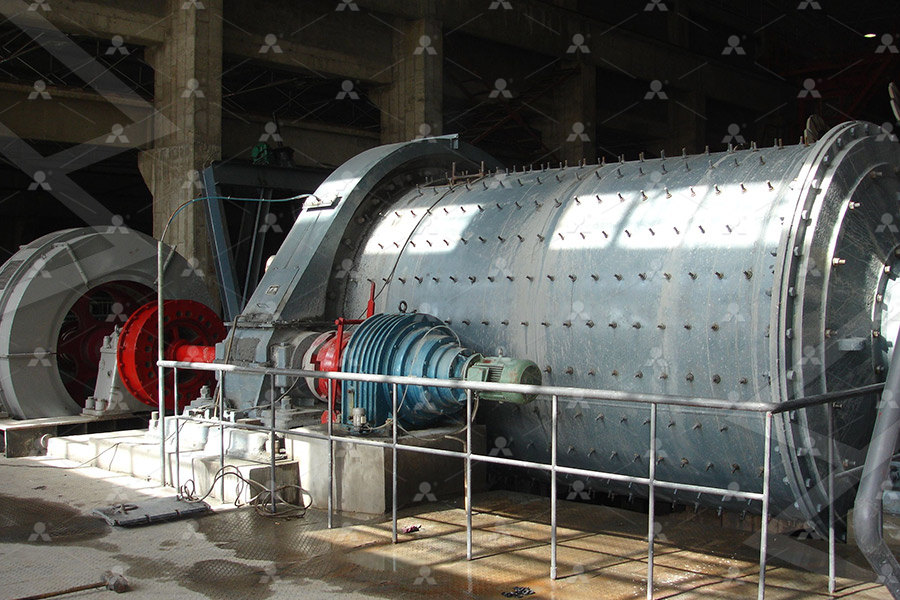

Rotor ore grinding mill

Rotor Beater Mill SR 300 RETSCH

The Rotor Beater Mill SR 300 is suitable for coarse and fine size reduction It can process dry, soft, mediumhard, organic and inorganic substances For Rotor and Beater Mills are ideal for precrushing and fine comminution of soft to mediumhard, brittle, fibrous and temperaturesensitive materials in analytic laboratories or industry The sample is comminuted at high speed by impact and shearing forcesRotor / Beater Mills – fritschThe Hockmeyer HCP Immersion Mill utilizes rapid recirculation milling technology to achieve a smaller particle size and tighter particle distribution and is faster than any other technology in the marketplaceRotor mill HCP Hockmeyer Equipment CorporationThe valuable minerals are finely disseminated in the ore body requiring a primary circuit grind of 75µm Because of increasing primary mill throughput (>950t/h), the flotation feed grind usually comes coarser This highlights the need to enhance Cu regrinding to improve mineral Energy efficient rotor design for HIGmills Swiss Tower Mills

Rotor Mills fast easy sample preparation RETSCH

The rotor mill series includes Ultra Centrifugal Mills, Rotor Beater Mills and Cross Beater Mills Depending on the particular instrument they are suitable for the preliminary and fine size reduction of soft, fibrous and also hard materialsThe ZM 300 achieves a maximum speed of 23,000 rpm (rotor peripheral speed 118 m/s) and produces particles which are 15 to 20 % finer in comparison, depending on the material The higher speed has a particularly positive impact Laboratory Ultra Centrifugal Mill ZM 300 RETSCHSIMINE Gearless mill drives’ rpms can be tailored to your operations at any time, and are infinitely variable and uncomplicated Whether manually or fully automatic – rpms can be adjusted to account for the properties of the ore, resulting in significantly less wear to the mill liningSIMINE Gearless mill drives SiemensThe patented IsaMill is a transformation in grinding technology based on high intensity stirred milling The IsaMill was developed for fine grained orebodies that needed a step change in processing efficiency to be economic The IsaMill Rotor agitator mill IsaMill NETZSCH Grinding

.jpg)

Outotec Higmill – EnergyEfficient HighIntensity Grinding

Compared to conventional flat surface discs, the vaned rotors also enable a significant improvement in grinding efficiency to the target grind size thanks to the improved media agitation and improved power transfer between the rotor surface and media bead massMetso Outotec HIGmillTM is an advanced and energyeficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and GrindForceTM rotor technology to produce a finer grind for mineral liberationStirred mills MetsoFind your rotor mill easily amongst the 280 products from the leading brands (WAMGROUP, IKA, Fritsch GmbH, for ore for cement concrete for clinker rotor grinding mill PULVERISETTE 14 premium line Rotational speed: 6,000 rpm 22,000 rpmRotor mill, Rotor lump breaker All industrial manufacturersMill ZM 200 ensures rapid grinding results Together with its extremely efficient operation the ZM 200 can prepare 100 samples or more per day for analysis More on page 4 2 RotoR MillS 3 The rotor mill series includes Preliminary size reduction Sample dividers ultra centrifugal mills, rotor beater mills and cross beater mills Depending on Size reduction with Rotor Mills

Rotor mill ZM 300 Retsch GmbH DirectIndustry

Rotor mills are used for highspeed size reduction of soft to mediumhard as well as temperaturesensitive or fibrous materials The powerful Ultra Centrifugal Mill ZM 300 provides maximum grinding performance combined with ease of use Find out all of the information about the NETZSCH Grinding Dispersing product: rotor agitator mill IsaMill Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale Exhibit with us horizontal for ore wet grindingRotor agitator mill IsaMill NETZSCH Grinding Dispersing 2017年6月2日 Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the grinding media Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates Semiautogenous mills are basically the same autogenous mills, but with the addition of balls, similar to those in ball millsHow it Works: Crushers, Grinding Mills and PulverizersEight IPEC Rotormill models are available, ranging from 30 to 750 horsepower These include: Model 1300: Our smallest unit: 30 HP, 500 CFM, twostage rotor Approximately 45” tall and 900 lbs Ideal for smallbatch or lowthroughput processingLong Gap Mill for Pulverizing and Milling Rotormill Prater

Rotor Mills Retsch GmbH PDF Catalogs DirectIndustry

ROTOR MILLS Ultra Centrifugal Mill ZM 200 The powerful drive of the innovative Ultra Centrifugal Mill ZM 200 ensures rapid grinding results Together with its extremely efficient operation the ZM 200 can prepare 100 samples or more per day for analysis More on page 4 ROTOR / BEATER MILLS Rotor and Beater Mills for deagglomerating, precrushing, and fine comminution of soft to mediumhard, brittle, fibrous and temperaturesensitive materials in analytic laboratories or industry The sample is comminuted at high speeds of up to 22,000 rpm by impact and shearing forces The final fineness of the samples depends on the selected Rotor / Rotor / Beater Mills Fritsch Milling and SizingFind out all of the information about the LCI product: rotor grinding mill LM05 Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of saleRotor grinding mill LM05 LCI DirectIndustryThe Rotor Mill Pulverisette 14 is an allpurpose mill for rapid crushing of mediumhard to soft substances Grinding temperaturesensitive materials is also possible with the variable speed rotor mill The extremely high rotor speed enables fast Laboratory Rotor Mill Pulverisette 14 Lavallab

.jpg)

Rotor mill HCP Hockmeyer Equipment Corporation

Find out all of the information about the Hockmeyer Equipment Corporation product: rotor mill HCP Building materials grinding mill; Ore grinding mill *Prices are pretax They exclude delivery charges and customs duties and do This diagram shows a comparison of the Hammer Mill HM 200 with two rotor mills The extremely high sample throughput of the HM 200 is RETSCH’s powerful hammer mill is ideally suited for preliminary crushing and fine Hammer Mill HM 200: For Laboratory Pilot PlantVideo credit: shsbjq / CC BYSA 40 Specifications Important specifications when selecting grinding mills and pulverizers include, The size of the mill can range from pilot/lab to production, eg, 35 to 1600 cu ft; Feed size, material, and hardness of feed must be considered; Output size ranges; Mills can handle dry or wet input, or both; Mills operate in batches or continuouslyGrinding Mills and Pulverizers Selection Guide: Types, Features In summary, the main difference between a sample mill and a grinding mill is their scale of operation and primary purpose, The rotor mill series includes Ultra Centrifugal Mills, Rotor Beater Mills, Cross Beater Mills and the cyclone mill Twister, each designed for specific sample processing needs Rotor Mills 1 Ultra Centrifugal Mill ZM 300Sample Mills for preparing samples RETSCH

.jpg)

P14 Rotor Mill fritsch

Benefit from two functions in one extra powerful, compact solution with the FRITSCH P14 Rotor Mill Send us your sample for test grinding your special substances with the new P14 Rotor Mill We will determine the optimum grinding parameters and impress you with outstanding results as well as a detailed grinding protocolIt adopts rotor type grinding, multilayer grinding cutter head, strong shearing force and dispersing force, which can be used for the disintegration of agglomerates, Tobacco stem grinding mill production line of a tobacco company in Liuyang 800kg/h Technical ParametersRotor Mill ALPA Powder Equipmentthe vertical mill, but allows it to be closely coupled with a cyclone or filterreceiver when required This mill’s classifier wheel and impact rotor have independent drives, and the mill can handle the same grinding applications as the vertical mill Combined How to operate an air classifier mill to meet your fine grinding The Autogenous Mill, also known as AG Mill, is a type of grinding mill used in the mining industry This machine uses ore and rock itself as grinding media to perform its job Unlike other types of mills that use steel balls or rods for grinding materials, the Autogenous Mill relies on the material being ground to break itself into smaller piecesUnderstanding the SAG Mill in Copper Ore Mining Process

A Comparative Study of New and Traditional Designs

2015年6月22日 Schematic of the test stand: 1 = modified hammer mill (WIR RB13), 2 = flexible claw clutch (PolyNorm), 3 = torque meter with tachometer (MIR 20), 4 = belt transmission, 5 = 7 kW electric motor The other class of mills are "attrition" or grinding mills Impact mills pulverize the material upon impact The feasibility of impact mills was greatly enhanced by the mechanization and engineering of the Industrial RevolutionPrior to the industrial revolution, milling was primarily done by attrition or grinding the material between two surfaces [1]Impact mill WikipediaInline and offline colloid mill MCB The MCB is a mill with stainless steel, perforated plates or corundum grinding elements used for fine grinding and homogenization of liquids, pasty and viscous products, capable to reduce the Colloid mill COLLOID MILL BACHILLER MixingGrindForce’s vaned rotors enable a significant improvement in grinding efficiency to the target grind size 1000 100 Specific Grinding Energy (kWh/t) Specific Grinding Energy 10 100 Particle size (µm) 1000 GrindForce rotor Flat discs Specific Grinding Energy (kWh/t) versus the particle size (P80, µm) showing consistent reduction in energy consumption of approximately Outotec Higmill – EnergyEfficient HighIntensity Grinding

ZM 200 Ultra Centrifugal Mill Glen Mills, Inc

The Ultra Centrifugal Mill ZM 200 is a high speed rotor mill with unmatched performance 6tooth rotor / 12tooth rotor / 24tooth rotor / 8tooth minirotor: Material of grinding tools: stainless steel, titanium, steel 14404, stainless steel with wearresistant coating:Coarse powder grinding mill is engaging in crushing various rocks and stones into coarse powder and small Rotor Diameter /mm: 750: 900: 1150: Rotor Width/ mm: 800: 1200: 1500: Rotor Speed/ r CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates Coarse Powder Grinding Mill SBM Ultrafine Powder TechnologyMore powerful frequency converter With a more powerful frequency converter, the Speed Rotor Mill PULVERISETTE 14 classic line ensures that the motor output is precisely matched to the grinding material Your advantage: faster sample feeding, a constant rotational speed and a higher throughput The welldesigned LED display in the ergonomic operating panel with Variable Speed Rotor Mill PULVERISETTE 14 classic line / The drying and dispersing modified rotor mill is a very efficient mechanical mill with multiple rotors on its vertical shaft Multilayer grinding cutter head, strong shearing force and breaking power, can be connected to hot air source for multiple purposes, and realize the functions of drying, dispersing and modifying at the same timeRotor Mill for drying, dispersing and modifying ALPA Powder

.jpg)

Mill, Grinding mill All industrial manufacturers

Final grain size: 74 µm 400 µm Rotational speed: 21 rpm Output: 16 t/h 50 t/h Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which is widely used The mill is filled with a suitable grinding media and the area between each disc is essentially an individual grinding chamber As a result the mill is effectively 8 grinding chambers in series The media is set in motion by the action of the grinding discs which radially accelerate the media towards the shellIsaMill Technology Used in Effecient Grinding CircuitsFind your rotor mill easily amongst the 280 products from the leading brands (WAMGROUP, IKA, Fritsch GmbH, for ore for cement concrete for clinker rotor grinding mill PULVERISETTE 14 premium line Rotational speed: 6,000 rpm 22,000 rpmRotor mill, Rotor lump breaker All industrial manufacturersMill ZM 200 ensures rapid grinding results Together with its extremely efficient operation the ZM 200 can prepare 100 samples or more per day for analysis More on page 4 2 RotoR MillS 3 The rotor mill series includes Preliminary size reduction Sample dividers ultra centrifugal mills, rotor beater mills and cross beater mills Depending on Size reduction with Rotor Mills

Rotor mill ZM 300 Retsch GmbH DirectIndustry

Rotor mills are used for highspeed size reduction of soft to mediumhard as well as temperaturesensitive or fibrous materials The powerful Ultra Centrifugal Mill ZM 300 provides maximum grinding performance combined with ease of use Find out all of the information about the NETZSCH Grinding Dispersing product: rotor agitator mill IsaMill Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale Exhibit with us horizontal for ore wet grindingRotor agitator mill IsaMill NETZSCH Grinding Dispersing 2017年6月2日 Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the grinding media Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates Semiautogenous mills are basically the same autogenous mills, but with the addition of balls, similar to those in ball millsHow it Works: Crushers, Grinding Mills and PulverizersEight IPEC Rotormill models are available, ranging from 30 to 750 horsepower These include: Model 1300: Our smallest unit: 30 HP, 500 CFM, twostage rotor Approximately 45” tall and 900 lbs Ideal for smallbatch or lowthroughput processingLong Gap Mill for Pulverizing and Milling Rotormill Prater

.jpg)

Rotor Mills Retsch GmbH PDF Catalogs DirectIndustry

ROTOR MILLS Ultra Centrifugal Mill ZM 200 The powerful drive of the innovative Ultra Centrifugal Mill ZM 200 ensures rapid grinding results Together with its extremely efficient operation the ZM 200 can prepare 100 samples or more per day for analysis More on page 4 ROTOR / BEATER MILLS Rotor and Beater Mills for deagglomerating, precrushing, and fine comminution of soft to mediumhard, brittle, fibrous and temperaturesensitive materials in analytic laboratories or industry The sample is comminuted at high speeds of up to 22,000 rpm by impact and shearing forces The final fineness of the samples depends on the selected Rotor / Rotor / Beater Mills Fritsch Milling and SizingFind out all of the information about the LCI product: rotor grinding mill LM05 Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of saleRotor grinding mill LM05 LCI DirectIndustry