Waste pyrolysis carbon black ore mill

Carbon black production characteristics and mechanisms from

2024年1月1日 Pyrolysis is a promising way to treat the waste tires for high value carbon black production However, the carbon black formation mechanism is still unclear due to the 2023年2月5日 Hightemperature pyrolysis of waste tires is a promising method to produce highquality carbon black In this study, carbon black formation characteristics were investigated Production mechanism of highquality carbon black from high 3 天之前 The pyrolysis of waste tires offers an environmentally friendly solution to the global tire waste problem Pyrolytic carbon black (PCB) is an important byproduct that can be Demineralization strategies of carbon black derived from pyrolysis 2024年1月11日 This study aims to recycle lowquality recycled carbon black (rCB) from waste tire pyrolysis, addressing the challenges posed by organic residues (up to 5 wt% bituminous substances, 1122 mg/kg PAH) This causes Recycling of LowQuality Carbon Black Produced by

Assessment of Recovered Carbon Black Obtained by Waste Tires

2017年3月11日 Steam water thermolysis (SWT) of tires, a hybrid of pyrolysis and solvolysis, is a good alternative to valorize waste tires Recovered carbon black (rCB), which can be 2023年3月6日 In this work, an experiment was carried out to produce commercially viable carbon black from waste tire A detailed investigation of the physical and chemical properties Recycling of waste tire by pyrolysis to recover carbon black: an 2022年3月9日 Pyrolysis enables the recovery of both energy and material from endoflife tires, yielding valuable gas, liquid, and solid fractions The latter, known as recovered carbon black (rCB), has been extensively researched in the last Production and Upgrading of Recovered Carbon Black 2023年1月15日 The recycling of valuable carbon black (CB) of pyrolysis carbon black (CBp) from waste tires is important considering the conservation of secondary resources and the Desulfurisation and ash reduction of pyrolysis carbon black from

Influence of Pyrolytic Carbon Black Derived from Waste

2023年8月18日 In order to guide the development of new industrial continuous rotary kiln reactors and achieve highperformance pyrolytic carbon black (CBp), this study was conducted to investigate the relationship between the physical 2022年3月12日 Pyrolysis carbon black (PCB) is a main product during the pyrolysis of waste tires Using PCB to partially replace carbon black has drawn great attention Herein, PCB is used to replace commercial carbon black N234 in a solutionpolymerized styrenebutadiene rubber (SSBR)/butadiene rubber (BR)/silica compound used for tire treadsEffect of Pyrolysis Carbon Black from Waste Tire on the 2023年2月5日 The yield of carbon black obtained from waste tire pyrolysis under different conditions is shown in Fig 1 b It could be found that the yield of carbon black gradually increased with the pyrolysis temperature and residence time From 1000 °C to 1300 °C, the yield of carbon black increased dramatically from about 3–10% to 22–27%Production mechanism of highquality carbon black from high 2023年4月7日 If waste tires can be fully cracked, 30%35% of carbon black can be extracted from one ton of waste tires Although carbon black has a wide range of uses in a broad sense, the carbon black that has just been extracted is still Tire pyrolysis carbon black deep processing grinding

.jpg)

Recovery of high pure pyrolytic carbon black from waste tires by

2022年11月10日 The principal component of pyrolytic char from waste tires is carbon black for rubber reinforcement, thus known as CBp (Martínez et al, 2013; Tian et al, 2021)Compared with commercial carbon black, the significant difference from CBp is high ash content, including silicon (Si), zinc (Zn), sulfur (S) and calcium (Ca) compounds, which originate from various additives Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, which grinds the carbon black to a smaller, finer grainThese kinds of carbon black are more exquisite and have higher reinforcing performanceCarbon Black Processing Plant Process Carbon Black from Tyres2023年1月15日 The traditional treatments of waste tires mainly include stacking, landfill, combustion or incineration, rubber powder regeneration, and pyrolysis (Parthasarathy et al, 2016)Although the combustion of waste tires can quickly alleviate the stacking problem and generate electricity through heat recovery (Cheng et al, 2021), it also produce a lot of toxic Desulfurisation and ash reduction of pyrolysis carbon black from waste the solid fraction of pyrolysis: recovered carbon black (rCB), its characteristics and potential reuse in tires Upgrading processes of rCB by various aftertreatments are reviewed As a reference, fossil based carbon black manufacturing, its use as rubber reinforcing filler, and its key material characteristics are discussed The differencesRECOVERED CARBON BLACK FROM WASTE TIRE PYROLYSIS

.jpg)

Recovered carbon black from waste tire pyrolysis: Characteristics

A suitable aftertreatment is also developed to further enhance its characteristics Finally, the recovered carbon is used to partially substitute the fossilbased carbon black in rubber compounds KW Recovered carbon black KW Sustainable tire manufacturing KW Waste tire pyrolysis KW Circular economy U2 103990/199polystyrene waste using microwave assisted pyrolysis The results indicated the when the reaction conditions were controlled it is possible obtain valueadded products and also minimize the plastic pollution 2 Methodology 21 Materials Carbon black was supplied from Cabot Carbon Ltd with a medium particle size of 150 μm Expanded polystyreneMicrowave assisted pyrolysis of expanded polystyrene waste using carbon 2022年8月15日 During the pyrolysis process, the waste tires can be utilized to produce pyrolysis carbon black (CBp), pyrolysis oil and pyrolysis gas The CBp, known as pyrolytic char or recovered carbon black, is consisted of carbon black, like used in tire manufacturing, with ash and solid tar adsorbed on its surface [8] Structure optimization of pyrolysis carbon black from waste tire 2017年4月1日 Carbon black from waste of tire industry has potential to be recycled through two steps ie pyrolysis and demineralization The treatment without and with pyrolysis prior to demineralization is done to identify the effect of temperatures on agglomerate size, morphology, elemental analysis, and surface function group Based on DTA analysis, temperatures at 225 Recycled carbon black from waste of tire industry: thermal study

.jpg)

Carbon Black Processing Machine to Improve the

2016年4月27日 Municipal Solid Waste Sorting Machine; Carbon Black Processing Machine; by rose qian BMF Series of Carbon Black Processing Machine In Pyrolysis Industry: The coarse carbon Tyre Pyrolysis 2G BioPOWER Figure 1: EU waste hierarchy Figure 2: Component manufactured with 100% ‘recovered’ carbon black (rCB) Contact Howard Jackson 2G BioPOWER, 93 Mill Court, Ashford, Kent, TN24 8DP T: +44 (0)1233 2gbiopower E: howardjackson@2gbiopowerBiomass and Waste Pyrolysis A Guide to UK Capabilities2020年6月24日 The main chemical composition of pyrolysis carbon black of waste tires is C, O, Cu, Zn and so on The content of ash and fine powder in pyrolysis carbon black is high, and the 300% elongation Basic Properties of Pyrolysis carbon black of Waste Tyres and 2020年11月6日 Pyrolysis is a feasible solution for environmental problems related to the inadequate disposal of waste tires, as it leads to the recovery of pyrolytic products such as carbon black, liquid fuels and gases The characteristics of pyrolytic carbon black can be enhanced through chemical activation in order to produce the required properties for its application In Characterization of Chemically Activated Pyrolytic Carbon Black

.jpg)

Effect of pyrolysis carbon black from waste tires on the

2020年2月4日 Several lab approaches have prepared PCB from waste tires in the literature, TGA pyrolysis, 6 meltextrusion pyrolysis, 7,8 and bed reactor pyrolysis 9 Regenerated carbon black was found to have a higher surface area, elongation at break, and heat buildup, but a lower curing speed, modulus, and a comparable state of cure, dispersion, hardness, tensile strength, 2021年11月30日 INTRODUCTION Pyrolysis is the key process in carbon nanomaterial synthesis [], bulk carbon production [5, 6], fabrication of carbonbased devices [], fuel generation from organic waste [] and molecule fragmentation for their analysis via gas chromatography–mass spectroscopy (GC–MS) []Primary examples of the technologically significant carbon materials A comprehensive review of the pyrolysis process: from carbon 2004年7月11日 This study addresses reprocessing of oils derived from wastetire pyrolysis into carbon black a valuable feedstock for the manufacture of tires, other rubber products, paints, pigments, ink CARBON BLACK DERIVED FROM WASTE TIRE PYROLYSIS OIL2020年11月1日 The demineralized recovered carbon black obtained from both acids together with a reference carbon black (N550) were characterized by elemental and proximate analyses, surface area, ash composition by XRF, and morphology by SEM and TEM A comprehensive surface chemistry analysis by FTIR and TPDNH 3 was also conductedRecycling of waste tire by pyrolysis to recover carbon black

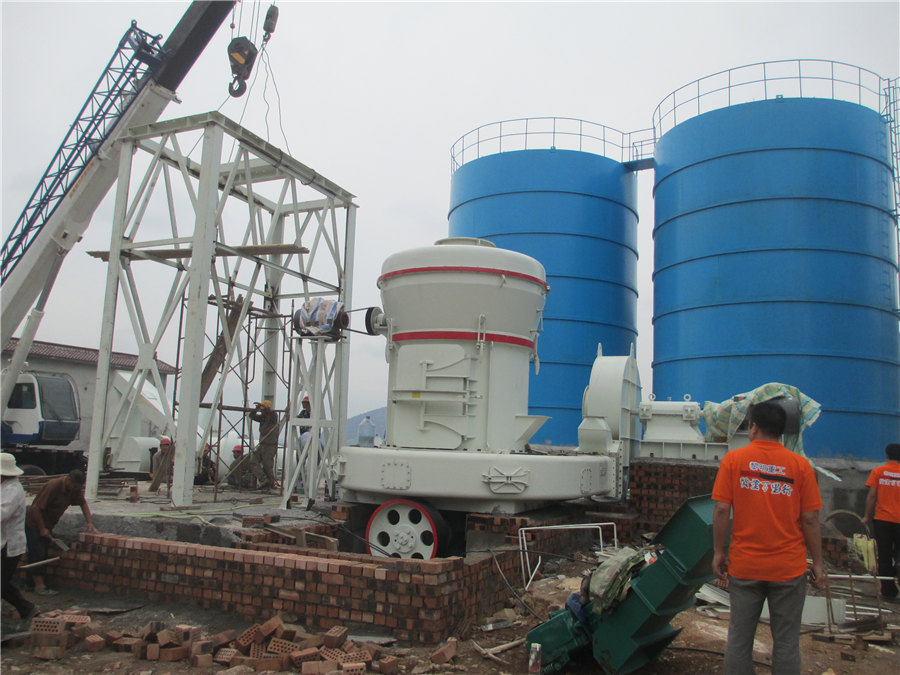

carbon black processing machine, tyre pyrolysis carbon black

Type:Waste Tyre Pyrolysis Plant for Carbon black Capacity:120 tone per furnace Live Chat Carbon black grinding mill/grinder mill Application field:Designed for carbon black super fine grinding, to solve the problem of cabon black light character Type:HGM carbon black grinding mill/carbon black grinder mill Capacity:130 t/h Live ChatKlean's tire pyrolysis and gasification technology was developed in Japan in the early 1970s and was the world's first countries to commercially process endoflife tires (ELT) using thermal technologies that were specifically designed to recover oil and energy from waste tiresTire Pyrolysis Produces Recovered Carbon Black Marine Fuel2013年12月1日 According to researchers (Fazara et al, 2014;Hita et al, 2016;Williams, 2013), pyrolysis of wasted tyres could transform the used tyres into gas, oil, steel and carbon black waste (recycled Production of carbon black from the waste tires 2022年3月9日 Increasing awareness regarding fossil fuel dependence, waste valorization, and greenhouse gas emissions have prompted the emergence of new solutions for numerous markets over the last decades The tire industry is Production and Upgrading of Recovered Carbon Black

A Model of Pyrolysis Carbon Black and Waste Chicken Feather

More than 800 million waste tires are abandoned each year globally, with an annual increase of 4% Approximately 13 million scrap tires are produced annually in China, with an annual growth rate of 6%–8% (Li et al 2020)The comprehensive utilization of waste tires in China includes renovation (Xu et al 2020), reclaimed rubber (Lin et al 2020), rubber powder (Liu et al 2020), By pyrolysis process, which is mentioned previously, a high pyrolyzed carbon black content component was produced as a byproduct with approximately 3035 wt% yields of the tire, which is known as coke or pyrolyzed carbon black This contains 95 wt% carbon black, and more than 3 wt% sulfur [5] Therefore, the produced carbon black couldSolving Ecological Problem of Pyrolysis Carbon Black (PCB)Production and Upgrading of Recovered Carbon Black from the Pyrolysis of EndofLife Tires Sebastião M R Costa Sebastião M R Costa 1 Department of Chemistry, Dombek V Study of carbon black obtained by pyrolysis of waste scrap tyres J Therm Anal Calorim 2013;111:1475–1481 doi: 101007/s1097301223404 [Google Scholar] 51Production and Upgrading of Recovered Carbon Black from the Pyrolysis 2021年12月1日 Recovery of high pure pyrolytic carbon black from waste tires by dual acid treatment Journal of Cleaner Production, Volume 374, 2022, Recycling of waste tire by pyrolysis to recover carbon black: Alternative environmentfriendly reinforcing filler for natural rubber compounds Composites Part B: Engineering, Volume 200, Preparation and characterization of carbon black (CB) using

.jpg)

Acid Demineralization and Characterization of Carbon Black

2013年1月1日 Carbon black from waste of tire industry has potential to be recycled through two steps ie pyrolysis and demineralization The treatment without and with pyrolysis prior to demineralization is Carbon black grinding machine is for process crude carbon black produced from tire/plastic pyrolysis process to fine powder used for carbon black required products This grinding machine is mainly used to pulverize various nonflammable and unexplosive materials less than 93scale Moh’s hardness and 6% humidity, in the industries of glass, rubber, pesticide, ceramic, paint, Carbon black grinding machineAuxiliary Equipment2023年5月3日 Waste tires are also known as “black pollution”, and pose significant risks to human health and ecosystems The pyrolysis process can recover valuable products such as natural gas, oil, and Activation of waste tire pyrolysis carbon black by ResearchGate2022年3月12日 Pyrolysis carbon black (PCB) is a main product during the pyrolysis of waste tires Using PCB to partially replace carbon black has drawn great attention Herein, PCB is used to replace commercial carbon black N234 in a solutionpolymerized styrenebutadiene rubber (SSBR)/butadiene rubber (BR)/silica compound used for tire treadsEffect of Pyrolysis Carbon Black from Waste Tire on the

.jpg)

Production mechanism of highquality carbon black from high

2023年2月5日 The yield of carbon black obtained from waste tire pyrolysis under different conditions is shown in Fig 1 b It could be found that the yield of carbon black gradually increased with the pyrolysis temperature and residence time From 1000 °C to 1300 °C, the yield of carbon black increased dramatically from about 3–10% to 22–27%2023年4月7日 If waste tires can be fully cracked, 30%35% of carbon black can be extracted from one ton of waste tires Although carbon black has a wide range of uses in a broad sense, the carbon black that has just been extracted is still Tire pyrolysis carbon black deep processing grinding 2022年11月10日 The principal component of pyrolytic char from waste tires is carbon black for rubber reinforcement, thus known as CBp (Martínez et al, 2013; Tian et al, 2021)Compared with commercial carbon black, the significant difference from CBp is high ash content, including silicon (Si), zinc (Zn), sulfur (S) and calcium (Ca) compounds, which originate from various additives Recovery of high pure pyrolytic carbon black from waste tires by Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, which grinds the carbon black to a smaller, finer grainThese kinds of carbon black are more exquisite and have higher reinforcing performanceCarbon Black Processing Plant Process Carbon Black from Tyres

Desulfurisation and ash reduction of pyrolysis carbon black from waste

2023年1月15日 The traditional treatments of waste tires mainly include stacking, landfill, combustion or incineration, rubber powder regeneration, and pyrolysis (Parthasarathy et al, 2016)Although the combustion of waste tires can quickly alleviate the stacking problem and generate electricity through heat recovery (Cheng et al, 2021), it also produce a lot of toxic the solid fraction of pyrolysis: recovered carbon black (rCB), its characteristics and potential reuse in tires Upgrading processes of rCB by various aftertreatments are reviewed As a reference, fossil based carbon black manufacturing, its use as rubber reinforcing filler, and its key material characteristics are discussed The differencesRECOVERED CARBON BLACK FROM WASTE TIRE PYROLYSISA suitable aftertreatment is also developed to further enhance its characteristics Finally, the recovered carbon is used to partially substitute the fossilbased carbon black in rubber compounds KW Recovered carbon black KW Sustainable tire manufacturing KW Waste tire pyrolysis KW Circular economy U2 103990/199Recovered carbon black from waste tire pyrolysis: Characteristics polystyrene waste using microwave assisted pyrolysis The results indicated the when the reaction conditions were controlled it is possible obtain valueadded products and also minimize the plastic pollution 2 Methodology 21 Materials Carbon black was supplied from Cabot Carbon Ltd with a medium particle size of 150 μm Expanded polystyreneMicrowave assisted pyrolysis of expanded polystyrene waste using carbon

Structure optimization of pyrolysis carbon black from waste tire

2022年8月15日 During the pyrolysis process, the waste tires can be utilized to produce pyrolysis carbon black (CBp), pyrolysis oil and pyrolysis gas The CBp, known as pyrolytic char or recovered carbon black, is consisted of carbon black, like used in tire manufacturing, with ash and solid tar adsorbed on its surface [8]