Ore grinding mechanism comprehensive analysis diagram

.jpg)

Mechanism characteristic analysis and soft measuring method

2018年11月1日 An analysis of the mill load measuring problem in the practical grinding process, the mill grinding mechanism based on numerical simulation, and the soft measuring method of 2021年1月8日 ore The criteria for selecting the samples can take several different forms The most comprehensive form is to explore the entire deposit for hardness variance Depending on A CRITICAL REVIEW OF GRINDING DESIGN PROCEDURES FOR THE Techniques involving carbon and sulphur speciation, Quantitative XRay Diffraction (QXRD), Scanning Electron Microscopy (SEM) and Optical Microscopy (OM) were used to characterise Ultra fine grinding circuit for whole ore and concentration 2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding Ore Grinding SpringerLink

46.jpg)

Grinding Contribution and Quantitative Separation of Impact and

2023年8月3日 In summary, the paper proposes for the first time a new grinding analysis method that quantitatively separates and characterizes the grinding contribution of the impact and 2023年7月22日 Ore crushing is the process of breaking, splitting, extrusion, impacting, and grinding of large solid ore with external force to reduce the particle size of large ore materials Ore Crushing SpringerLinkfundamental to understand how ore textures influence the generation of ore particles and their properties This contribution outlines the processes used to generate and concentrate ore All About Particles: Modelling Ore Behaviour in Mineral Elements2014年6月1日 Automation in mineralogical (and chemical) laboratories from sample preparation to analysis has been the baseline for these improvements This paper will highlight key Ore characterization, process mineralogy and lab automation a

(PDF) Quantitative analysis of ore texture breakage characteristics

2022年5月1日 Quantitative analysis of ore texture breakage characteristics affected by loading mechanism: Multivariate data analysis of particle texture parameters May 2022 Minerals Engineering 181(3):Download scientific diagram The generalized process flowsheet for Pyhäsalmi sulphide ore processing from publication: Mineralogical and surface chemical characterization of flotation feed and The generalized process flowsheet for Pyhäsalmi Download scientific diagram Overview of the iron ore beneficiation process in the Qidashan concentrator (based on Yong 2005) from publication: Flotation of Iron Ores: A Review A tremendous Overview of the iron ore beneficiation process in the Qidashan 2021年6月17日 In this research, the mechanism of the original magnetite improving iron ore reduction during the magnetization roasting process was explored using ore fines and lump ore samples(PDF) The Efficient Improvement of Original Magnetite in Iron Ore

Crushing Plant Flowsheet DesignLayout 911Metallurgist

2016年3月11日 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less2017年3月1日 Principal component analysis, Qmode factor analysis, etc) are finding increasing applications in ore classification based on other characterisation techniques (eg QSEM,(PDF) Characterisation of Minerals and Ores: On the 2024年3月1日 Analysis of the changing law of residual stress and material micromechanisms under high efficiency deep grinding: (a) Residual stress with (a) strong grinding (Huang, 2009); (b) change in coarse grinding area angle (Yin et al, 2018), (b) Mechanism of efficient deep grinding removal of microscopic morphology (Zhang et al, 2021), (c) Relationship between grinding Residual stress generation in grinding: Mechanism and modeling2019年7月15日 Manganese ore smelting is reviewed in terms of processing parameters such as feed material particle sizes, energy input methods, heat transfer modes, smelting mechanisms, experimental findings on A Review of Ore Smelting in High Carbon Ferromanganese Production

Prediction of iron ore mineral liberation behavior using the

2022年5月1日 A combined grinding and liberation model was studied to predict the liberation characteristics of iron ore comminuted by a ball mill Comminution characteristics were obtained using the onesize 2022年4月18日 For the iron ore with a Fe content of 2491%, a pilotscale study of preconcentration, suspension magnetization roasting, grinding, and lowintensity magnetic separation was conducted, and an Novel Technology for Comprehensive Utilization of LowGrade Iron OreDownload scientific diagram The whole separation process flowsheet of onestage grinding from publication: Effects of Multistage Grinding Process and Grinding Fineness on Desulfurization The whole separation process flowsheet of onestage Moreover, the grinding particle size in the grinding process is a very important parameter that is directly related to the grade of concentrated ore and metal recovery rate [3] [4] [5]Process and instrument diagram for the twostage

Grinding SpringerLink

2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems and been Download scientific diagram Gear form grinding with form wheel from publication: Estimation of residual stresses in gear form grinding using finite element analysis and experimental study based Gear form grinding with form wheel Download Scientific DiagramDownload scientific diagram Effect of grinding aids on the particle size distribution [74] from publication: A critical review on the mechanisms of chemical additives used in grinding and Effect of grinding aids on the particle size distribution [74]Download scientific diagram Conceptualization of ore blending procedure from publication: The effects of ore blending on comminution behaviour and product quality in a grinding circuit Conceptualization of ore blending procedure Download Scientific Diagram

.jpg)

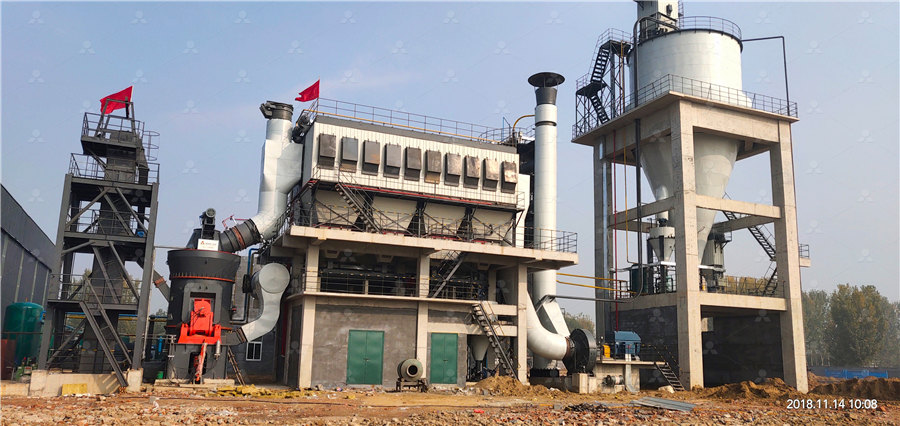

SAG Mill Grinding Circuit Design 911Metallurgist

2016年6月6日 Occasionally, secondary crushing is included in the original design but is often added as an additional circuit to account for harder ore (either harder than planned or becoming harder as the deposit is developed) or as a capitalefficient mechanism to boost throughput in Ultrasonic vibrationassisted grinding (UAG) has been proven to be a promising grinding ability improvement technique due to the grinding force reduction However, the reduction mechanism is still unclear due to the lack of knowledge on material softening and grain—workpiece contact conditions in UAG In this paper, we present a numerical and experimental study on ultrasonic Study on force reduction mechanism in ultrasonicassisted grinding grinding results to the inuence and composition of impact and grinding, it will undoubtedly be a major breakthrough in the grinding analysis theory, and it can provide an important theoretical basis for the optimal selection and adjustment of grinding media and the simulation and prediction of grinding results 2 Maerials t and Methods 21 Grinding Contribution and Quantitative Separation of Impact and 2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The effects of ore blending on comminution behaviour and

.jpg)

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 The mechanism of breakage is illustrated in [23] by a diagram shown in Fig 3 The left column of the figure shows the si ze distribution of the feed The applicationDownload scientific diagram Mechanism of grinding process from publication: INVESTIGATION OF THE CUTTING FORCES IN CREEPFEED SURFACE GRINDING PROCES This paper examines the value and Mechanism of grinding process Download Scientific Diagram2019年12月17日 For example, KatirciogluBayel et al (2019) explored the influence of grinding media filling level on energy consumption and ore crushing in a stirred media mill through experimentInfluence of Grinding and Classification Circuit on the 2024年8月2日 The beneficiation of lowgrade iron ores is a key research and development topic in the mineral processing industry The gradual exhaustion of highgrade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient lowquality iron ore beneficiation to meet steelmaking quality requirements This comprehensive review explores Exploring LowGrade Iron Ore Beneficiation Techniques: A Comprehensive

.jpg)

Processing of Moringa leaves as natural source of nutrients by

2017年6月23日 For this purpose, a comprehensive study has been carried out to increase the understanding of drying and flow characteristics of Moringa (leaves and powder) using different drying and grinding Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill2022年1月10日 In addition, the different grinding mechanisms of ball and rod milling were evaluated by analyzing the shape factor and surface roughness of the ground samplesSelective comminution and grinding mechanisms of spent 2023年11月21日 They summarized various methods for mill load (ML) detection, including soft measurement based on mathematical models, grinding sound analysis, vibration analysis, power analysis, ultrasonic analysis, and neural networkbased methods 32 Mohanty et al analyzed the vibration features of industrial wet ball mills using Microelectromechanical Systems (MEMS) Advances in vibration analysis and modeling of large rotating

.jpg)

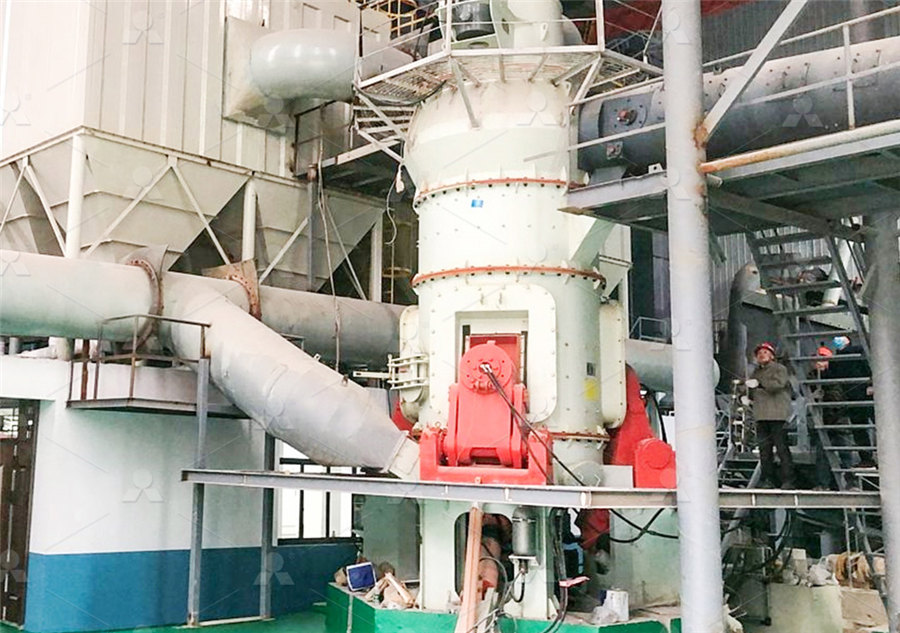

Research of iron ore grinding in a verticalrollermill

2015年3月15日 Furthermore, ore textures become more complex and the valuables are more finegrained, compared to ores of the last decades, requiring additional grinding for sufficient mineral liberation These trends may lead to a four times higher energy consumption for the comminution of the main metal ores in the year 2030 compared with today (Norgate and Download scientific diagram Intact ore and different types of breakage mode from publication: Breakage process of mineral processing comminution machines – An approach to liberation Mineral Intact ore and different types of breakage mode2022年5月1日 Quantitative analysis of ore texture breakage characteristics affected by loading mechanism: Multivariate data analysis of particle texture parameters May 2022 Minerals Engineering 181(3):(PDF) Quantitative analysis of ore texture breakage characteristics Download scientific diagram The generalized process flowsheet for Pyhäsalmi sulphide ore processing from publication: Mineralogical and surface chemical characterization of flotation feed and The generalized process flowsheet for Pyhäsalmi

.jpg)

Overview of the iron ore beneficiation process in the Qidashan

Download scientific diagram Overview of the iron ore beneficiation process in the Qidashan concentrator (based on Yong 2005) from publication: Flotation of Iron Ores: A Review A tremendous 2021年6月17日 In this research, the mechanism of the original magnetite improving iron ore reduction during the magnetization roasting process was explored using ore fines and lump ore samples(PDF) The Efficient Improvement of Original Magnetite in Iron Ore 2016年3月11日 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or lessCrushing Plant Flowsheet DesignLayout 911Metallurgist2017年3月1日 Principal component analysis, Qmode factor analysis, etc) are finding increasing applications in ore classification based on other characterisation techniques (eg QSEM,(PDF) Characterisation of Minerals and Ores: On the

.jpg)

Residual stress generation in grinding: Mechanism and modeling

2024年3月1日 Analysis of the changing law of residual stress and material micromechanisms under high efficiency deep grinding: (a) Residual stress with (a) strong grinding (Huang, 2009); (b) change in coarse grinding area angle (Yin et al, 2018), (b) Mechanism of efficient deep grinding removal of microscopic morphology (Zhang et al, 2021), (c) Relationship between grinding 2019年7月15日 Manganese ore smelting is reviewed in terms of processing parameters such as feed material particle sizes, energy input methods, heat transfer modes, smelting mechanisms, experimental findings on A Review of Ore Smelting in High Carbon Ferromanganese Production2022年5月1日 A combined grinding and liberation model was studied to predict the liberation characteristics of iron ore comminuted by a ball mill Comminution characteristics were obtained using the onesize Prediction of iron ore mineral liberation behavior using the 2022年4月18日 For the iron ore with a Fe content of 2491%, a pilotscale study of preconcentration, suspension magnetization roasting, grinding, and lowintensity magnetic separation was conducted, and an Novel Technology for Comprehensive Utilization of LowGrade Iron Ore