Limestone crushing process

11192 Crushed Stone Processing and Pulverized Mineral Processing

Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl, marble, shell, process flow diagram for limestone processing operations 3 list of tables 6 6 table 1 gross energy to produce one ton of limestone products table 2 water consumption for limestone quarrying and processing table 3 lci inputs for limestone quarrying and processing table 4 lci outputs for limestone quarrying and processing table 5Limestone Quarrying and Processing: A LifeCycle Inventorypreparation, calcinations, and hydration Stone preparation includes crushing screening, and washing it removes impurities Calcining is the heating of limestone to convert the calcium carbonate into calcium oxide This process is typically carried out in a rotary or vertical shaft kiln Required temperatures of the kilns exceed 1800 degreesLimestone and Crushed Rock Department of Energy1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for Limestone Aggregate Crushing JXSC Machine

.jpg)

Limestone crushing, sand making and grinding process

2022年7月20日 Application analysis of limestone crushing, sand making and grinding After testing by several cases and relevant departments, as long as the process of limestone processing sand and gravel materials is reasonable, the finished products can basically meet the requirements stated in the “Standards for Sand and Stone Quality and Inspection Methods for 2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for industries such as airport construction, water conservancy power stations, tall buildings, concrete mixing plants, etcLimestone Crushing And SandMaking Plant Eastman Rock The present invention is fit to alumina producer lime and prepares needed limestone crushing process requirement, increases boulder yield to greatest extent, reduces the generation of 0~18mm waste material, has improved the utilization rate of ore, has reduced the waste of limestone resourceAdopt the inventive method crushed product through experimental CNA Limestone crushing process Google Patents2023年2月14日 The limestone crushing process is a crucial step in the production of cement, as well as in other industries that utilize limestone as a raw material The process of crushing limestone involves several stages, each of which plays a critical role in ensuring that the final product meets the necessary specifications and standardsOptimized Limestone Crushing Process for Increased Efficiency

Limestone Crusher for Efficient Limestone Crushing Plant

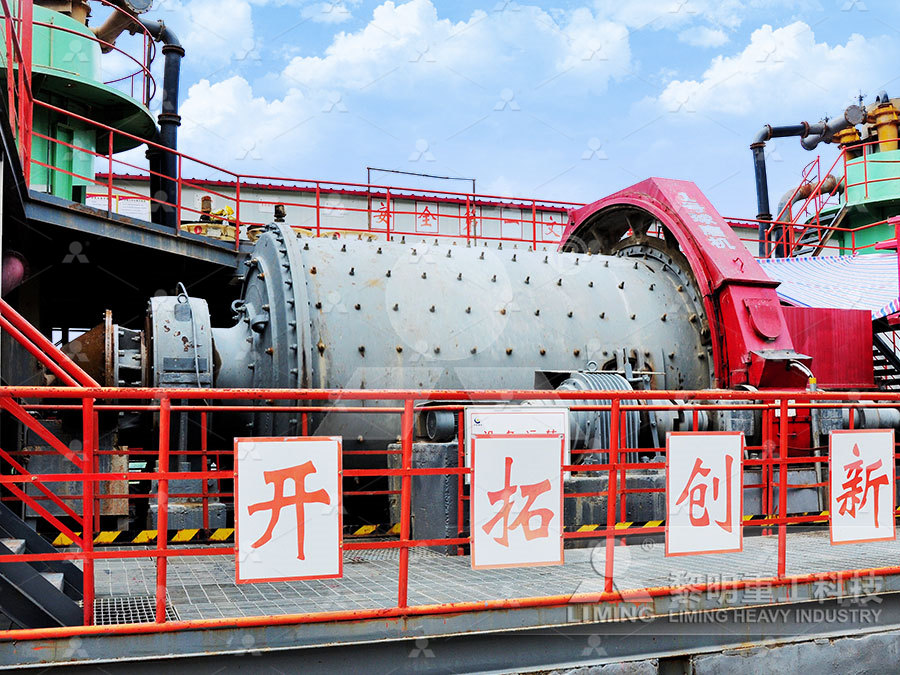

The limestone crushing process is a complex operation that requires a variety of limestone crusher and additional equipment to produce the desired material for its various uses Understanding the characteristics of different limestone crushers and how they operate is crucial for designing an efficient limestone processing operationThe limestone crusher is equipment that can crush large limestone gravels about 6001800mm into materials about 25mm or smaller It provides limestone crushed products in the construction industry because limestone is a key ingredient in the production of cement, concrete and other building materialsThe size and type of crushers may vary according to the specific What is Limestone Crusher? AIMIX GROUP2023年12月8日 Limestone crushing process Limestone or limestone resources are abundant, and the raw ore grade can generally meet the requirements of various industrial sectors Therefore, generally only simple mineral washing is required, and there is no need to use complex mineral processing processes for purificationLimestone crushing technology and equipment SBM Ultrafine Design the limestone crushing process, and briefly introduce the process designed by SBM experts Second, limestone crushing processing equipment SBM's equipment for this process has a vibrating feeder, a jaw crusher, two cone crushers, two circular vibrating screens, and a Limestone crushing process sbmchina

.jpg)

Limestone Crushing Solution Eastman Rock Crusher

Limestone generally adopts dry crushing process For metallurgical and construction use limestone, only the ore needs to be crushed and screened If you want to further produce fine powder limestone products, use a jaw 2023年3月27日 Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different applications Do’s Don’ts Of Limestone Rock Crushing Mellott2022年4月20日 Limestone crushing process Limestone or limestone are rich in resources, and the grade of raw ore can generally meet the requirements of various industrial sectors Therefore, it is generally only necessary to carry out simple ore washing and does not need to adopt a complex beneficiation process for purificationLimestone crushing and grinding production line SBM Ultrafine 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl, marble, shell, and slate Major mineral types processed by the pulverized minerals industry, a11192 Crushed Stone Processing and Pulverized Mineral Processing

.jpg)

Limestone Mill for Limestone Powder Grinding Limestone Crushing

Limestone is a massive stone material that is mined by a limestone crushing plant through a limestone crusher Its main component is calcium carbonate (CaCO3), and it also contains clay, dolomite, The limestone grinding process will start after the crushed limestone entering the millStay tuned for more exciting posts about crushing equipment! What Is A Limestone Crusher And What Are Its Uses? A limestone crusher is essentially a heavily built machine designed to reduce large rocks and stones, such as limestone, into much smaller pieces Its uses vary from residential and commercial to industrial construction projectsLimestone Crusher: What Is It How Does It Work?2024年1月23日 Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feeder The jaw crusher crushes large limestone blocks into Limestone crushing and screening production line introduction2024年7月15日 When crushing limestone with a mud content of less than 5% and a moisture content of less than 7%, and safety of the crushing process 3 cases of limestone crushing plants 1 Limestone crushing plant in Brazil Output Feed size Discharge granularity Application fields Equipment Limestone Crusher: An Edge Tool for Making Crushed Limestone

Experimental Study of the Crushing Characteristics of Single

2024年10月24日 The crushing process of material particles in a vertical shaft impact (VSI) crusher is highly complex It is hard to quantify and characterize the crushing behavior of particles In this work, an experimental setup for active impact crushing is designed and constructed to investigate the crushing behavior of particles in a VSI crusher Impact crushing experiments 2023年2月13日 This article states types of limestone crushing equipment and compares them in production efficiency and other pespectives to help you selecting the best limestone crushing equipment we will compare the different types of limestone crushing equipment and their efficiency in the production process to help you make informed decisionsWhat Is The Best Limestone Crusher Limestone Crushing AGICO2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing They can crush low to medium hardness materials such as limestone and coal, as well as materials Types of Crushers: Choosing the Right One for Each 2024年2月21日 The extracted limestone is then transported to the processing plant using heavy machinery such as bulldozers and dump trucks Crushing: Once the limestone reaches the processing plant, it undergoes primary The process of limestone aggregate making

A LifeCycle Inventory of Limestone Dimension Stone Quarrying

Crushing at Crushing Facility Figure 1 Process flow diagram for limestone quarrying operations 3 As shown in Figure 1, the first step in quarrying is to gain access to the limestone deposit This is achieved by removing the layer of earth, vegetation, and rock unsuitable for product—collectivelyThe limestone crushers and mills are effective for directinjection of dry sorbent lime or limestone during the CFB process Below you can explore our catalog of products that can complete a variety of limestone crushing applications Direct Fired Roller Mill PulverizersLimestone Mills Williams Crusher2019年11月11日 Limestone: A sedimentary rock and the most commonly used rock type for crushed stone in the United States This crushing and screening process is typically done at quarries Depending on the rock available at a construction site, crushers are hauled directly to the site for useThe Complete Guide to Crushed Stone and Gravel800 TPH Limestone Crushing Process The limestone crushing production line primarily consists of four processes: feeding, crushing, sand making, and screening It is typically composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, sand making machine, sand washing machine, belt conveyor system, centralized electric control panel and other necessary 800TPH TPH Limestone Crushing Process – Luoyang Dahua

Cement Production Demystified: StepbyStep Process and

Crushing the limestone rocks to get fine grounded limestone; Addition of clay and sands; Milling to have a fine mix of limestone, This process step is very energy intensive and is one of the main reasons why cement production is representing a large share of global greenhouse gas emissions The objective of using a kiln in the 2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the SIZE REDUCTION BY CRUSHING METHODS ResearchGateTo cook or “calcine” limestone, there must be a significant transfer of heat to the limestone In general, the heat transfer from the fuel source to limestone can be divided into two stages: Calcining – the kiln fuel is burned in the preheated air from the cooling zone and, as the limestone moves down the kiln, the heat turns the limestone into quicklime and carbon dioxide (CO 2 )How Lime is Madeprocess flow diagram for limestone processing operations 3 list of tables 6 6 table 1 gross energy to produce one ton of limestone products table 2 water consumption for limestone quarrying and processing table 3 lci inputs for limestone quarrying and processing table 4 lci outputs for limestone quarrying and processing table 5Limestone Quarrying and Processing: A LifeCycle Inventory

.jpg)

Limestone and Crushed Rock Department of Energy

preparation, calcinations, and hydration Stone preparation includes crushing screening, and washing it removes impurities Calcining is the heating of limestone to convert the calcium carbonate into calcium oxide This process is typically carried out in a rotary or vertical shaft kiln Required temperatures of the kilns exceed 1800 degrees1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for Limestone Aggregate Crushing JXSC Machine2022年7月20日 Application analysis of limestone crushing, sand making and grinding After testing by several cases and relevant departments, as long as the process of limestone processing sand and gravel materials is reasonable, the finished products can basically meet the requirements stated in the “Standards for Sand and Stone Quality and Inspection Methods for Limestone crushing, sand making and grinding process2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for industries such as airport construction, water conservancy power stations, tall buildings, concrete mixing plants, etcLimestone Crushing And SandMaking Plant Eastman Rock

CNA Limestone crushing process Google Patents

The present invention is fit to alumina producer lime and prepares needed limestone crushing process requirement, increases boulder yield to greatest extent, reduces the generation of 0~18mm waste material, has improved the utilization rate of ore, has reduced the waste of limestone resourceAdopt the inventive method crushed product through experimental 2023年2月14日 The limestone crushing process is a crucial step in the production of cement, as well as in other industries that utilize limestone as a raw material The process of crushing limestone involves several stages, each of which plays a critical role in ensuring that the final product meets the necessary specifications and standardsOptimized Limestone Crushing Process for Increased EfficiencyThe limestone crushing process is a complex operation that requires a variety of limestone crusher and additional equipment to produce the desired material for its various uses Understanding the characteristics of different limestone crushers and how they operate is crucial for designing an efficient limestone processing operationLimestone Crusher for Efficient Limestone Crushing PlantThe limestone crusher is equipment that can crush large limestone gravels about 6001800mm into materials about 25mm or smaller It provides limestone crushed products in the construction industry because limestone is a key ingredient in the production of cement, concrete and other building materialsThe size and type of crushers may vary according to the specific What is Limestone Crusher? AIMIX GROUP

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone crushing process Limestone or limestone resources are abundant, and the raw ore grade can generally meet the requirements of various industrial sectors Therefore, generally only simple mineral washing is required, and there is no need to use complex mineral processing processes for purification