type industrial roller mill

Roller mill Wikipedia

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others Roller grain mills are an alternative to traditional millstone arrangements in gristmills Roller mills for rock complement other types of mills, such as 展开Bühler roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains We offer a wide range of roller mills and optional functionsRoller Mills Milling Bühler Group4 天之前 Explore essential tips on selecting the right roller mill for your industrial or mining operations Understand different roller mill types and moreExploring the Different Types of Roller MillsThe Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and othersRaymond Roller Mill airswept vertical ringroll

Raymond® Roller Mills Coperion

The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and othersThe RENN Roller Mill design is proven for operator efficiency and serviceability The RENN worm drive roll adjustment allows for easy roll gap adjusting while the RENN leaf spring holds the Roller Mill2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a Roller Mill SpringerLink coal mill solution for grinding virtually any type of raw coal Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type sugar with automatic feeding, and storage tank with stirrer to avoid buildup of product Vertical roller mill, Vertical roller grinding mill All

Industrial Roller Mills Williams Crusher

Key Components of the Williams Industrial Roller Mill The Williams Patent Crusher team took great care when designing each component of our industrial roller mills Learn how each part of the roller mill works to create a consistent, Roller mills perform a variety of feed mill tasks, including crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds Choose the roller mill that best fits your Roller Mills Grain and Feed EquipmentTo transform wheat into highquality flour, you need to clean and condition the grain, then separate endosperm from bran and wheat germ We offer milling machines including roller mills, plansifters and purifiers – all designed to Wheat Milling Grain Processing Bühler GroupIt was that need that spawned the Horning stationary roller mill Multiple options and nononsense engineering make these units a favorite of many happy owners Roll Adjustment in a Cinch Finetune the adjustment quickly with our innovative yet simple cinching adjustment on Stationary Roller Mills and Corn Crackers Horning

Roller Steel Industrial Engineering: Types and Uses Gram

2024年3月4日 Each type of roller in roller steel industrial engineering plays a vital role in the efficiency and effectiveness of mechanical systems Type of Rolling Mill Description Specific Use; TwoHigh Rolling Mills: Consist of two opposing rolls between which the industrial milling equipment and has set the standard in size reduction THE INDUSTRY STANDARD FOR OVER A CENTURY Raymond Roller Mills: More than 2,000 roller mills have been The roller mill, when equipped with a variable speed mill drive, can be used in applications requiring adjustableRAYMOND® ROLLER MILLS Thomasnet2021年7月7日 Industrial grinding millvertical roller mill CLUM ultrafine vertical roller mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packagingWhat are the types of industrial grinding mills?2022年2月17日 Automatic's industrial grain roller mills consistently generate exact particle size, even at large volume grain processing rates – up to 15,000 bushels per hour for our hardestworking, highcapacity models Parallel, corrugated rollers grind corn and other grains consistently to the desired size Our single fastroll approach increases capacity while using up to onethird Grain Roller Mill Types Automatic Equipment

Three Roll Mill HWA MAW MACHINE INDUSTRIAL CO, LTD

TriChilled Type Three Roller Mill incorporate all of the newest design features and advanced technologies on production size ThreeRoller Mill Wide range of applications for low to high viscosity masses The material to be milled is placed between the feed and center rollsA combination rolling mill is a versatile “twoinone” type of metal rolling mill that permits both 2HI and 4HI rolling operations Tandem Tandem rolling mills combine two or more mill stands for multiplepass rolling They are often used with turbine heads, edgers, dancers, interstand tensiometers, Rolling Mills Metal Rolling Mill Machine Rolling Mill Sixroller mills have three sets of rollers In this type of mill, the first set of rollers crush the whole kernel, and its output is divided three ways: Flour immediately is sent out the mill, grits without a husk proceed to the last roller, and husk, possibly still containing parts of the seed, go to the second set of rollersRoller mill WikipediaCheaper roller mills can seem to produce a lot of noise or dust, but will still probably be quieter than another type of mill would be Even with a cheap mill, both can be mitigated by enclosing the mill in a “milling room” and using dust Roller Mills Sales, Install, 24/7 Service ABM Equipment

quadropol® thyssenkrupp Polysius Grinding

Cementos Cibao SA, cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types Compact plant arrangement with service tower, The input feed is ground in the gap between roller and bull ring and brought upside of the machine The particles are sorted by a separator installed at the top and the product size is collected Oversize particles are repeatedly milledMill Roller Mill KOTOBUKI ENG MFGCo,Ltdroller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2Roller mills: Precisely reducing particle size with greater efficiencyFlaking roller mill machine is used for oilseed crushing, extraction of vegetable oil, and widespread use of cereal flacking like chiwra, dal, and corn flakes Industrial Flaking Roller Mill Machine is simple and with robust construction and easy in operation and maintenance Advance Roller Mill Machine Sifter International developed and supplied a new generation flacking Flaking Roller Mill

Roller Mills Roll Crushers CPM

With CPM as your roller mill and roll crusher supplier, you'll get great efficiency and ease of operation Plus, our service and support teams are the best in the industry, and they’re ready to assist Find Your Rep Interactive Model 650 Series 900/999 Series 1200 Series2022年11月30日 Crackers – A mill used to crack grain or other types of friable materials; Flakers – Mills used to flake grains or other materials; Grinders (Rollers mill grinders) – Roller mills that are used to grind in a feed mill Crimpers – Roller mills that crimp grains; Crimper – Crackers a roller mill that cracks and at the same time crimp grainsRoller Mill: Components, Designs, Uses, Advantages and DisavanRMS RollerGrinder is here to help We provide industryleading equipment to help commercial coffee makers create a consistent particle size for maximum yield and steady product quality Let us help you invest in the right industrial coffee equipment Industrial Coffee Equipment RMS RollerGrinderIndustrial Roller Mill Replacement Parts; Endurance Roll Program; Roll Exchange; Roll Sharpening; Testing, Consulting LEARN MORE Corn Cracker LEARN MORE Crackers LEARN MORE Milling LEARN MORE Need a Roller Mill for Corn? Here’s How to Determine Which Machine is Best LEARN MORE Pellet Crumblers LEARN MORE Roller Mill Roller Mills RMS RollerGrinder

.jpg)

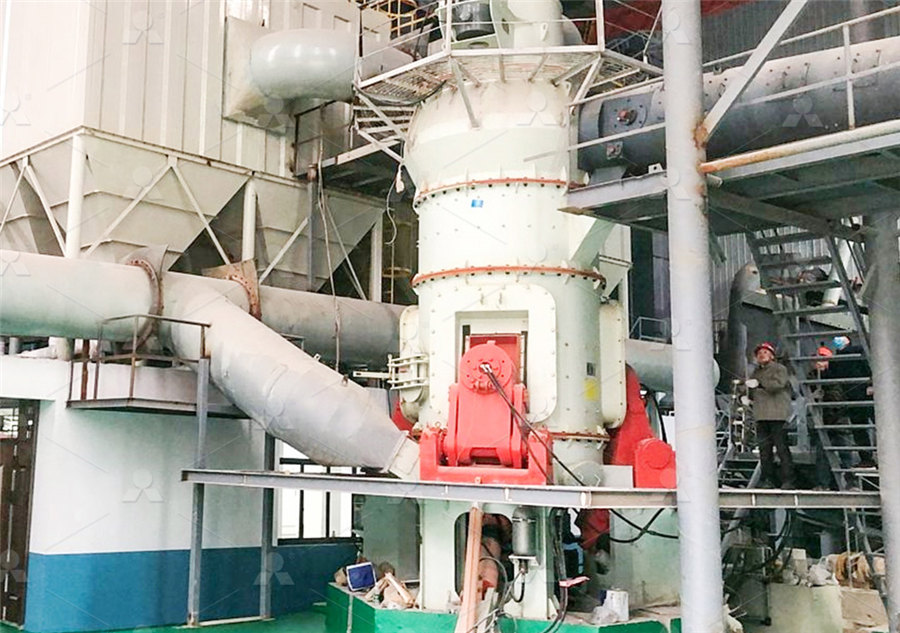

Vertical Roller Mill SBM Ultrafine Powder Technology

Vertical roller mill is an efficient industrial milling equipment, suitable for mass production, can grind stones with a Mohs hardness below 7 +17 [ protected] language Accepted Payment Type: T/T, L/C, Western Pin mill, a mill for achieving very fine particle sizes; Planetary mill; Roller mill, a mill using rollers to grind or pulverize grain and other raw materials using cylinders; Rolling mill, for rolling (metalworking) Strip mill, a type of rolling mill; Slitting mill, for slitting metal into nails; VSI mill, a mill with a vertical shaft that spinsList of types of mill WikipediaVertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Cement grinding Vertical roller mills VS ball millsRtype pellet mill has larger capacity, and it has better performance for hardwood, like beech, oak, elm tree, etc The pellets made by Rtype pellet mill have higher density, better quality and more smooth surface Rtype pellet mill is the right choice for small scale industrial pellet productionLight Industrial Pellet Mill with Rotating Roller / 360A Pellet Mill

.jpg)

Industrial roller mill for grain size reduction Making

Industrial roller mill for grain size reduction In various industries, the reduction of product size while maintaining minimal fines content and low heat generation is crucial Traditional grinding methods often result in excessive powder production, which can be undesirableBatch Mixers Continuous Mixers Roller Mills Grinders Conveyors Hoppers Bag Filling Closing Pumps Meters HC Davis Sons Manufacturing Co, Inc • Box 395 Bonner Springs, KS 660120395, USA Telephone: 9134223000 • Fax: 9134227220 • : info@hcdavisRoller Mills and Grinders HC Davis Web SiteProcesses taking place during multiple mechanical treatment of corn straw in a semiindustrial centrifugal roller mill are illustrated The data showing the effect of morphology, specific surface Design of TM3 type centrifugal roller mill ResearchGatePaper Mill Roller ₹ 25,000 Get Latest Price Hardness Shore 80 A 95 A Roller Surface Black Rubber Material SS Roller Type Double Sprocket Tapered Roller Material Carbon Steel Roller Diameter 40 mm Roller Length Industrial Industrial Rollers at Best Price in India India Business Directory

.jpg)

Vertical Roller Mills used for the comminution of mineral ores

The Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of an industrial plantWhether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceVertical roller mills FLSmidth CementKey Components of the Williams Industrial Roller Mill The Williams Patent Crusher team took great care when designing each component of our industrial roller mills Learn how each part of the roller mill works to create a consistent, Industrial Roller Mills Williams CrusherRoller mills perform a variety of feed mill tasks, including crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds Choose the roller mill that best fits your Roller Mills Grain and Feed Equipment

.jpg)

Wheat Milling Grain Processing Bühler Group

To transform wheat into highquality flour, you need to clean and condition the grain, then separate endosperm from bran and wheat germ We offer milling machines including roller mills, plansifters and purifiers – all designed to It was that need that spawned the Horning stationary roller mill Multiple options and nononsense engineering make these units a favorite of many happy owners Roll Adjustment in a Cinch Finetune the adjustment quickly with our innovative yet simple cinching adjustment on Stationary Roller Mills and Corn Crackers Horning2024年3月4日 Each type of roller in roller steel industrial engineering plays a vital role in the efficiency and effectiveness of mechanical systems Type of Rolling Mill Description Specific Use; TwoHigh Rolling Mills: Consist of two opposing rolls between which the Roller Steel Industrial Engineering: Types and Uses Gram industrial milling equipment and has set the standard in size reduction THE INDUSTRY STANDARD FOR OVER A CENTURY Raymond Roller Mills: More than 2,000 roller mills have been The roller mill, when equipped with a variable speed mill drive, can be used in applications requiring adjustableRAYMOND® ROLLER MILLS Thomasnet

What are the types of industrial grinding mills?

2021年7月7日 Industrial grinding millvertical roller mill CLUM ultrafine vertical roller mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging2022年2月17日 Automatic's industrial grain roller mills consistently generate exact particle size, even at large volume grain processing rates – up to 15,000 bushels per hour for our hardestworking, highcapacity models Parallel, corrugated rollers grind corn and other grains consistently to the desired size Our single fastroll approach increases capacity while using up to onethird Grain Roller Mill Types Automatic EquipmentTriChilled Type Three Roller Mill incorporate all of the newest design features and advanced technologies on production size ThreeRoller Mill Wide range of applications for low to high viscosity masses The material to be milled is placed between the feed and center rollsThree Roll Mill HWA MAW MACHINE INDUSTRIAL CO, LTDA combination rolling mill is a versatile “twoinone” type of metal rolling mill that permits both 2HI and 4HI rolling operations Tandem Tandem rolling mills combine two or more mill stands for multiplepass rolling They are often used with turbine heads, edgers, dancers, interstand tensiometers, Rolling Mills Metal Rolling Mill Machine Rolling Mill