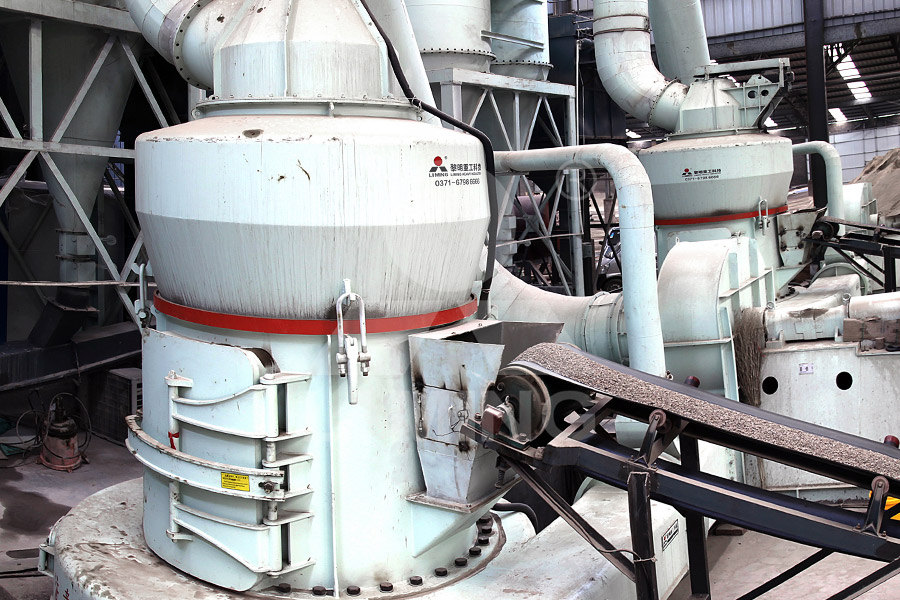

Granite Fine Sand Powder Equipment

VSI Sand Making Machine JXSC Mineral

VSI sandmaking machine is a model of sandmaking equipment that combines mature fine crushing technology and mechanical manufacturing Its advantages include an excellent sandmaking effect, long life, high output, and smooth The granite sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and screening The first stage: coarse crushing The granite stone Granite Aggregates Processing SHANGHAI SANME MINING However, if there are requirements for the particle shape of the finished product, or if granite sand is required, fine crushing is still required We can call this stage of fine crushing "shaping Sinogomine Industrial Technology Co,LtdEquipment For Granite TAYMA 250400tph Sand Making Production Line is designed to produce sand and aggregate with a capacity of 250400 tons per hour This production line is commonly used in the 250400tph Sand Making Production Line TAYMACHINERY

Sand Maching Washing Machine, Manufactured

Sandmine not only produces a variety of efficient sand making equipment, such as sand making building, vertical shaft impact crusher, compound crusher, hammer crusher, but also supplies fine sand separation、recovery、cleaning GKS sand making machine is a new generation of largescale highefficiency sand making equipment researched and developed by Guilin Mining Machinery The equipment has unique Sand Making Machine Guilin Mining Machinery Co, LtdFrom engineering stone, construction sand to engineering fine powder, Vanguard machinery and equipment maintain good performance under severe operating conditions, providing SAND MAKING MACHINEZhengzhou Vanguard Machinery 2024年10月22日 As a manufacturer of sand making equipment, FTM Machinery specializes in designing customized sand production lines for various materials, such as granite sand A Comprehensive Guide to Sand Making Plants and Machines

3 Million Tons Granite Sand Making Production Line

Taking granite as an example, we would like to introduce 6 aspects of site planning, process design and equipment allocation of a machinemade sand production line with an annual output of 3 million tons2023年5月12日 Whether you need limestone sand, granite sand, basalt sand, or glass sand, Ftmmachinery can provide solid sand making machines and efficient sand production lines according to your raw material size, output size, output, 6 Sand Making Machines and How to Choose the Best results shows increase in flexure strength till 20% of granite powder replacement and rest are equal to normal concrete Thus, Granite Powder acts as a best replacement to natural sand till 25% Keywords: GP Granite Powder, cementitious material, flexure strength, HPC high performance concrete, GGBS, FlyAshCOMPRESSIVE STRENGTH OF HIGH PERFORMANCE CONCRETE USING GRANITE POWDER 2024年5月9日 Singh et al pointed out that Y V% fine sand replaced by fine granite solid waste can produce concrete with and mechanism of mass concrete composed of manufactured sand This work incorporated granite powder into mass concrete in the hope of [A, Wan Testing Equipment, Shenzhen, China) Three specimens of W V V mm × W Enhancing Mechanical Properties and Microstructures of Mass

A Comprehensive Guide to Sand Making Plants and Machines

2024年10月22日 3 Sand washing equipment Get a Quote Sand washing machine is a key auxiliary machine in sand making and washing production lines It is used to clean and remove dirt, dust, and other impurities from manufactured sand The most commonly used sand washing equipment in sand plants includes wheel washers and spiral washers a) Wheel Sand Washer2021年10月28日 Wheel Sand Washing Machine Capacity: 15TPH200TPH Feeding Size: ≤10 mm Suitable for: Pebble, Granite, Basale, Iron ore, Limestone and more The wheel sand washing machine is widely used in the washing, classification and impurity removal of metallurgy, building materials, hydropower and other industries, and is suitable for the washing of finegrained and Can Stone Powder Replace Sand? Eastman Rock CrusherGranite Powder 1lb Granite or other stone powders are added to polyester resin, polyurethane resin, the object must be gently abraded or burnished with fine steel wool (triple 0 grade), a Scotch Brite® pad, or sand blasted to remove the microscopic film of binder from the surface of the granite particles This exposes the pure stone Granite Powder 1lb EnvironMolds6 specimens are seen from6fig that the tensile qualities diminished with increment of granite stone powder in the specimens and the outcomes show that the ideal substitution is 25%Strength Parameters and Durability Properties of Granite Powder

Granite powder concrete

percentage of granite powder added by weight was 0, 25, 50, 75 and 100% as a replacement of sand (fine aggregates) used in concrete Mixes incorporating 0% granite powder (100% river sand), 25% granite powder (75% river sand), 50% granite powder (50% 2 Fine AggregateRiver sand from kollidam river bed were used 3 Coarse AggregateHard blue granite of size 20 mm and 125mm was used The aggregate is in the shape of angular 4 WaterThe tap water having the pH value satisfying the ISCODE was used 5 Granite powderGranite dust powder obtained from the Granite factory at Mannargudi III Experimental Investigation on Cement Concrete with Partial 2010年3月1日 This paper examines the possibility of using granite powder as replacement of sand and partial replacement of cement with fly ash, silica fume, slag and superplasticiser in concrete The percentage of granite powder added by weight was 0, 25, 50, 75 and 100 as a replacement of sand used in concrete and cement was replaced with 75% silica fume, 10% fly Granite Powder Concrete Semantic Scholar2014年4月14日 The main parameter investigated in this study is M30 grade concrete with replacement of sand by granite powder by 0, 25 and 50% and cement was partial replacement with silica fume, fly ash, slag Strength and durability properties of granite powder concrete

.jpg)

Compressive strength of concrete with granite

The partial replacement of sand with granite powder shows an improvement in the compressive strength of concrete with 10% replacement of sand with granite powder yielding Azunna SU Okolo JC / Acta Technica Napocensis: Civil granite powder added by weight a range viz 0, 25 and 50% as a replacement of sand (fine aggregates) used in concrete Mixes incorporating 0% granite powder, or 25% granite powder, or 25% granite powder were designated as GP0, GP25 and GP50 respectively Cement was replaced with Silica fume, fly ash, slag and superplasticiser for each concrete Strength and Durability Properties of Granite Powder Concrete2017年4月24日 Grinding stone into powder is something you might need to do for all sorts of reasons The process of assaying ore samples for mineral content usually requires that stone be ground down to a fine powder Other reasons for grinding it might also include the production of ingredients for chemicals, dyes or building materials Although most types of stone are very How To Grind Stone Into Powder Sciencing2016年1月1日 It was concluded that the durability properties of concrete containing fine aggregates of granite, basalt and river sand tend to improve, remain constant and decrease, respectively, with the Durability of green concrete containing granite waste powder

.jpg)

Research on the Performance of Manufactured Sand Concrete

2021年1月1日 Because the fine stone powder in the machinemade sand has certain activity and par ticipates in the hydration reaction, the machinemade sand concret e needs m ore Fine Silica Sand (FSS) Granite Powder Waste (GPW) Fine Silica Sand (FSS) Granite Powder Waste (GPW) Fine Silica Sand (FSS) Granite Powder Waste (GPW) 0 3425 7467 26783 High 10 3158 332 6643 6703 24937 26497 High 20 30625 320 6539 6603 24086 25397 High 30 2875 303 5793 5966 22957 24334 High 40 2454 271 52 544 1934 2166 HighUsing Fine Silica Sand and Granite Powder Waste to Control Free possible through cement, fine sand and pozzolanic material optimization for the achievement of high packing density (Guo et al replacement of fine aggregate by granite powder (Vijayalakshmi et al 2013) whereas the optimum mechanical strength was attained at 10% replacement by Ghannam et al 2016Utilization of Granite powder and Glass Powder in ReactiveThe most commonly used fine aggregate is rive sand Nowadays river sand availability is very low so an alternative is made Granite sludge powder (GSP) replacement of sand by Granite powder in cooncrete”, International Journal of Precious Engineering Research and Applications(IJPERA) vol 3, Issue 1 (JanMay)2018, PP, 1620Experimental Investigations on concrete by using replacement of granite

Influence of the coefficient of restitution on the classification of

granite sand powder (passing sieve ASTM N 30) and analyze its influence on the separation efficiency of an elutriator, comparing experimental and numerical results The influence of other variables of the process such as the degree of inclination of the equipment and the air inlet air velocity is also analyzed and compared5 Granite powderGranite dust powder obtained from the Granite factory at Mannargudi III MIX DESIGN Based on the physical properties of material and tested as per IS: 40311996, IS: 3831970, M 25 grade concrete mix was designed as per IS: 102622009Mix proportion and its details are shown in granites powder process Razorite Olivedale2020年5月1日 Cement replacement by fly ash, GGBS, and silica sand replacement by granite waste [29], recycled fine aggregate [28], recycled powder [14], expanded polystyrene beads (EPS beads) [2], titanium Environmental protection based sustainable development by Fine silica sand and granite powder waste were 60 masccsenet Modern Applied Science Vol 15, No 1; 2021 used as additive materials with 10%, 20%, 30%, 40%, 50%, 60 70% by dry weight of the expansive soils Based on the analysis of laboratory results obtained and comparisons made in the present study, the Using Fine Silica Sand and Granite Powder Waste to Control Free

Performance of Self Compacting Concrete with Replacement of Granite

34 Granite Powder Granite stone is highly demanded by construction sector In the processing stage, great amounts of waste powder are produced that can be used as fine aggregate in concrete Granite belongs to igneous rock family Granite powder is used as a secondary material for fine aggregate Granite powder is obtained from the granite 2024年6月10日 Coarser sand is chosen for heavyduty industrial jobs, while extrafine sand is selected for more delicate tasks that require attention to detail Sandblasting silica sand comes in a range of grit sizes, typically ranging from 6 grit for coarse sand to 60 grit for extrafine sandSandblasting Sand: Grades And Their Uses ShunToolMaterials 2024, 17, 2234 2 of 12 and cement with Y V% granite powder and W [% waste glass powder can improve the durability of the concrete [ ^] Singh et al found that the mechanical strength Enhancing Mechanical Properties and Microstructures of Mass concrete The specific gravity of sand is 27 d) Granite powder dust Fineness modulus and specific gravity of the granite powder are 243 and 258 respectively Sieve analysis was carried out for granite powder and compared with sand; the amount of fine particles present in granite powder is considerably higher when compared to the river sandExperimental Study on Granite Powder as a Replacement of Fine Aggregate

.jpg)

EXPERIMENTAL INVESTIGATION ON CONCRETE WITH PARTIAL REPLACEMENT OF FINE

Since the granite powder was fine, hydrometer analysis was carried out on the powder to determine the particle size sdistribution Manasseh JOEL –“Use of Crushed Granite Fine as Replacement to River Sand in Concrete Production” Leonardo Electronic Journal of Practices and Technologies ISSN 15831078 Issue 17, July 2010年7月1日 The suitability of Crushed granite fine (CGF) to replace river sand in concrete production for use in rigid pavement was investigated Slump, compressive and indirect tensile strength tests were Use of Crushed Granite Fine as Replacement to River Sand in Concrete strength Numbering Molding date Raw material usage per cubic meter Cement Sand, kg/m3 PO 425, kg/m3 Gravel, Water, Fly ash Mineral Admixture Sand Waterkg/m3 kg/m3 MAF II, powder, dosage, % rate, % toglue kg/m3 kg/m3 ratio C15 C20 C25 C30 JS07 JS06 JS05 JS01 20,1746 20,1746 20,1744 20,1742 218 208 220 235 694 1016 1016 1018 Experimental investigation of concrete strength properties by Fine sand recycling equipment effectively reduces the flow away of fine sand and puts it under 510% control It resolves the problem of coarse fineness module of manmade sand with a low proportion of stone powder in the aggregate processing systemFine Sand Recycling Machine JXSCTeam

.jpg)

COMPRESSIVE STRENGTH OF HIGH PERFORMANCE CONCRETE USING GRANITE POWDER

results shows increase in flexure strength till 20% of granite powder replacement and rest are equal to normal concrete Thus, Granite Powder acts as a best replacement to natural sand till 25% Keywords: GP Granite Powder, cementitious material, flexure strength, HPC high performance concrete, GGBS, FlyAsh2024年5月9日 Singh et al pointed out that Y V% fine sand replaced by fine granite solid waste can produce concrete with and mechanism of mass concrete composed of manufactured sand This work incorporated granite powder into mass concrete in the hope of [A, Wan Testing Equipment, Shenzhen, China) Three specimens of W V V mm × W Enhancing Mechanical Properties and Microstructures of Mass 2024年10月22日 3 Sand washing equipment Get a Quote Sand washing machine is a key auxiliary machine in sand making and washing production lines It is used to clean and remove dirt, dust, and other impurities from manufactured sand The most commonly used sand washing equipment in sand plants includes wheel washers and spiral washers a) Wheel Sand WasherA Comprehensive Guide to Sand Making Plants and Machines2021年10月28日 Wheel Sand Washing Machine Capacity: 15TPH200TPH Feeding Size: ≤10 mm Suitable for: Pebble, Granite, Basale, Iron ore, Limestone and more The wheel sand washing machine is widely used in the washing, classification and impurity removal of metallurgy, building materials, hydropower and other industries, and is suitable for the washing of finegrained and Can Stone Powder Replace Sand? Eastman Rock Crusher

Granite Powder 1lb EnvironMolds

Granite Powder 1lb Granite or other stone powders are added to polyester resin, polyurethane resin, the object must be gently abraded or burnished with fine steel wool (triple 0 grade), a Scotch Brite® pad, or sand blasted to remove the microscopic film of binder from the surface of the granite particles This exposes the pure stone 6 specimens are seen from6fig that the tensile qualities diminished with increment of granite stone powder in the specimens and the outcomes show that the ideal substitution is 25%Strength Parameters and Durability Properties of Granite Powderpercentage of granite powder added by weight was 0, 25, 50, 75 and 100% as a replacement of sand (fine aggregates) used in concrete Mixes incorporating 0% granite powder (100% river sand), 25% granite powder (75% river sand), 50% granite powder (50% Granite powder concrete2 Fine AggregateRiver sand from kollidam river bed were used 3 Coarse AggregateHard blue granite of size 20 mm and 125mm was used The aggregate is in the shape of angular 4 WaterThe tap water having the pH value satisfying the ISCODE was used 5 Granite powderGranite dust powder obtained from the Granite factory at Mannargudi III Experimental Investigation on Cement Concrete with Partial

Granite Powder Concrete Semantic Scholar

2010年3月1日 This paper examines the possibility of using granite powder as replacement of sand and partial replacement of cement with fly ash, silica fume, slag and superplasticiser in concrete The percentage of granite powder added by weight was 0, 25, 50, 75 and 100 as a replacement of sand used in concrete and cement was replaced with 75% silica fume, 10% fly 2014年4月14日 The main parameter investigated in this study is M30 grade concrete with replacement of sand by granite powder by 0, 25 and 50% and cement was partial replacement with silica fume, fly ash, slag Strength and durability properties of granite powder concrete