Reasons for 38x13 Cement Grinder Full Grinding

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

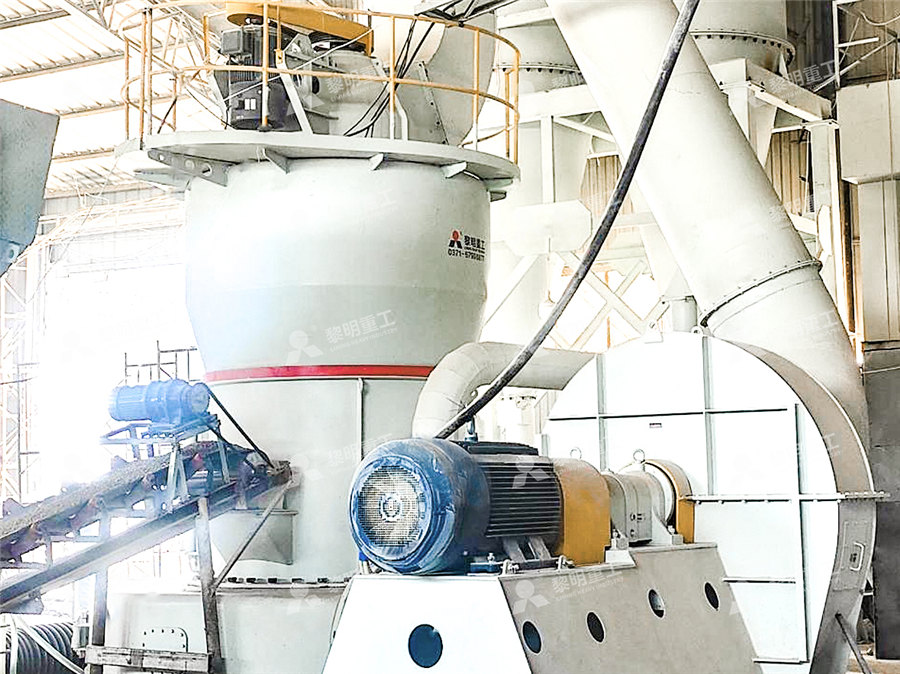

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinder s with ball mills Ball mills have been There is potential to optimise conventional cement clinker grinding circuits and in the last decade significant progress has been achieved The increasing demand for “finer cement” products, (PDF) Cement grinding optimisation Alex Jankovic Academiacommon solution to grind raw materials and cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding BALL MILLS Ball mill optimisation Holzinger ConsultingCement grinding In Table 1, three common cement grinding systems are compared on their electrical consumption for a typical 3500 Blaine ordinary portland cement (OPC) Roller press Thomas Holzinger, Holzinger Consulting, grinding system

.jpg)

Overview of cement grinding: fundamentals, additives, technologies

2017年5月19日 PDF Grinding is an essential operation in cement production given that it permits to obtain fine powder which reacts quickly with water, sets in few Find, read and 2016年10月5日 Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of EnergyEfficient Technologies in Cement Grinding IntechOpenGas flow, advantage and disadvantage in the Raw mill and Cement mill installations – Grindability concept and the effects of intergrinding materials of different grindability – Ball mill grinding CEMENT GRINDING COURSE The Cement Institute2019年1月3日 Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as Clinker grinding technology in cement manufacturing

Concrete Grinding: Everything You Need to Know

2023年4月13日 Concrete grinding is the process of sanding down the surface of the concrete to reduce offsets, trip hazards, or uneven areas Generally, the goal of concrete grinding is to 2023年4月3日 In this guide, we will walk you through the basics of concrete grinding, introduce you to different types of grinders, and share techniques, maintenance tips, and safety Concrete Grinder 101: The Insider's Guide to Concrete Grinding2024年4月13日 Cleaning the Grinder: If you're using power tools like a grinder, it's crucial to clean them thoroughly after each use Grinding can generate a significant amount of dust, which can accumulate in the tool and affect its performance To clean the grinder, unplug it from the power source and remove any debris or dust using a brush or compressed airThe Ultimate Guide To Using A Concrete Grinder ShunTool2021年10月12日 Using a concrete grinder: Technique matters When grinding concrete, take your time and allow the machine to do its work If you move too fast, odds are you’ll end up redoing some areas Browse United Rentals’ full lineup of How to Grind Concrete Using a Concrete Grinder United Rentals

.jpg)

Concrete Grinders, Planers and Scarifiers for Rent

Selections include concrete grinders, also known as a planers, milling machines and rotary cutters, ideal for grinding concrete to leave it smooth and level For our full list of concrete grinders planers, view the items below For more The angle grinder is an excellent choice for several reasons: it is small, mobile, versatile, and inexpensive – meaning it may just be the best tool to assist you with your concrete grinding project In this article, we’ll go over: The tools that are required for this project; A stepbystep guide to grinding concrete with angle grinderGrinding Concrete with Angle Grinder: Steps for a Smooth FinishGrinding aids also serve to reduce coating problems in cement storage and enhances cement strengths GRINDING MILLS Mills will be selected according to type most suitable for required capacity and duty and for overall power consumption Cement grinding operation may be performed in one of the following mill setups Ball and tube millsCement Grinding Cement Plant OptimizationThe MAXIMUM Masonry Grinding Disc is designed for grinding down most common types of masonry, including concrete, block, limestone, sandstone, and tile This multipurpose wheel is constructed from resinoid bonded with aMAXIMUM Type 28 Carbide Grinding Wheel/Disc for Masonry, Cement

.jpg)

1500W 125mm Concrete Grinder Full Boar SiteId

1500W 125mm Concrete Grinder $31000 The FULL BOAR 125mm 1500W Concrete Grinder is designed for grinding, levelling, cleaning and finishing concrete surfacesThe high powered 1500W motor delivers superior power and torque while the variable speed and ergonomic DHandle ensures efficient grinding on various surfaces such as concrete, brick and o Finished grinding may consume 25 – 50 kWh/t cement, depending on the feed material grindability, additives used, plant design especially the required cement fineness Cement grinding is the single biggest consumer of electricity in the manufacturing process Whichever the mill types, grinding is inherently inefficientImprovements in New Existing Cement Grinding Mills by Tim The Full Boar 180mm 2000W Concrete Grinder is designed for grinding, levelling, cleaning and finishing of concrete surfaces The highpowered 2000W motor delivers superior power and torque plus the soft grip rear handle and support handle ensures efficient grinding on various surfaces such as concrete, brick and tileFull Boar 2000W 180mm Concrete Grinder Bunnings AustraliaCement Grinding Guide Free download as Word Doc (doc), PDF File (pdf), Text File (txt) or read online for free This document discusses operating cement grinding processes efficiently It covers factors that influence grinding efficiency like product fineness, grindability of raw materials, and process parameters Product fineness is important for cement strength and can be Cement Grinding Guide PDF Mill (Grinding) Scribd

Bruxism (teeth grinding) Symptoms and causes Mayo Clinic

2017年8月10日 If you notice that your child is grinding his or her teeth — or has other signs or symptoms of bruxism — be sure to mention it at your child's next dental appointment Request an appointment There is a problem with information submitted for this request Review/update the The final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 45% gypsum and possible additives, into the final product, cement In a modern cement plant the total consumption of electrical energy is about 100 kWh/t The cement grinding process accounts for approx 40% if this energy consumptionCEMENT GRINDING SYSTEMS INFINITY FOR CEMENT EQUIPMENT2023年4月3日 Edging refers to the ability of a grinder to reach tight corners and edges If you're working on a job that requires precise edging, you'll want to choose a grinder with a smaller grinding head and adjustable edging features Electrical Concrete Grinder 101: The Insider's Guide to Concrete Grinding2024年4月12日 The diamond cup grinder is the most common type of cup grinder used for concrete grinding It is called "diamond" cup grinder because the grinding wheel is embedded with industrialgrade diamonds, which are the hardest material known to man These diamonds serve as cutting edges and help to grind down and smooth out concrete surfaces effectivelyThe Best Cup Grinder For Concrete: A Comprehensive Guide

.jpg)

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Metso Minerals Process Technology AsiaPacific, Brisbane , Australia email: alexjankovic@metso Dr Walter Valery, Metso Minerals Process Technology AsiaPacific, Brisbane, Australia Eugene Davis, Metso Minerals AsiaPacific, Perth, Australia ABSTRACT The current world consumption of cement is about (PDF) Cement grinding optimisation Alex JankovicHusqvarna PG 280 is a single disc floor grinder that you can quickly convert for edge grinding on both sides It efficiently grinds adhesives, paint, epoxy and spackle With a grinding width of 11 in it is suitable for small to medium concrete areas It is available in both 1 and 3phase versions Designed to facilitate an ergonomic work position, it is easy and convenient to useConcrete Floor Grinder Rental The Home Depot Canada2022年2月28日 Comparing dry and wet grinding curves in a ball mill in the same condition (an equal amount of materials and grinding media has been used on each pair of wetdry experiments) (Fig 17) indicated two significant differences at higher power values of wet grinding, specifically when speed exceeded 06 critical speed and for higher ω Pmax in the Grinding SpringerLink

.jpg)

(PDF) Review of the Effect of Grinding Aids and Admixtures on the

2023年11月6日 The influence of the GAs incorporation in cement grinding on properties such as workability and setting times of the placed concrete and/or mortar has been covered in this review1400W 125mm Concrete Grinder $31000 The FULL BOAR 125mm 1500W Concrete Grinder is designed for grinding, levelling, cleaning and finishing concrete surfacesThe high powered 1500W motor delivers superior power and torque while the variable speed and ergonomic DHandle ensures efficient grinding on various surfaces such as concrete, brick and 1400W 125mm Concrete Grinder Full Boar SiteId2023年11月10日 However, for more extensive grinding, such as removing a top layer of concrete, it would be advisable to use specialized equipment such as a floor grinder or walkbehind grinder These machines are designed to reach deeper into the concrete and provide a thorough grinding experience, ensuring a more professional and efficient resultHow to Grind Down Concrete Floor for Smoother Finishes2023年6月7日 Learning to use an angle grinder properly can take a fair bit of practice Specifically, you’ll often need to practice a variety of techniques for accomplishing the many jobs assigned to an angle grinder Along the way, 7 Types of Angle Grinder Discs and Their Uses

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on 2023年10月19日 Therefore, efficient grinding techniques and technologies are employed to minimize energy use and reduce production costs, contributing to the sustainability of the cement industry Types of Clinker Grinding Techniques used in cement manufacturing process Clinker grinders are an important part of the cement manufacturing processClinker Grinding Techniques in Cement Manufacturing JM 2019年10月11日 AGICO Cement is a cement grinding plant manufacturer, we'd like to helps you learn more about cement grinding plant and cement grinding machines Skip to content +86 s about blog contact EN ES Menu Menu Home; Cement Equipment Raw Material processing Stacker And Reclaimer;Cement Grinding Plant Overview Cement Grinding Unit AGICO Cement2020年7月2日 Concrete grinders are not designed to take out nicks and gouges, so take care not to grind too deeply into the stone Keep your grinder moving at all times to avoid burn marks and hot spots Be sure you wear protective eye gear, gloves, and a dust mask whenever grinding concrete dust or polishing concrete Clean The Entire Floor Before Grinding6 Ways to Grind a Concrete Floor Onfloor

27" Cement Grinders Concrete Polisher Machines HightechGrinding

High Tech Grinders Canada provides customers with the best selection of cement grinders and concrete polisher machines all across Canada Shop now! for only CA$ 14,88615 at HightechGrinding Canada!2023年6月22日 How to Grind Down Concrete Using a Concrete Grinder Concrete grinding takes some practice to get it right The steps below cover the process, though pros may add a few more steps based on the desired result 1 Put a Coarse Grit Grinding Pad on the Concrete Grinder Put the coarsest grit grinding pad you have on the concrete grinder head(s)How to Grind Concrete Three Ways Angi2020年11月25日 Grinding the surface secures that minimal flaws will be manageable Early prevention is one crucial benefit of polishing the concrete Diamond grinding clears the cement top layer Seeing the whole slab will help contractors to identify early signs of failing concrete Thus, a quick remedy to tiny cracks or crumbling cement will be employed4 Reasons to Get Diamond Grinding for your Pool DeckAnd this is what we call wet grinding Gas vs Electric Grinders The concrete floor grinder you get will either run on gas or electricity, and each has its advantages and disadvantages If a power outlet is readily available and accessible in the area Best Concrete Grinders ( 2021 Reviews ) ToolsPros

.jpg)

The Ultimate Guide To Using A Concrete Grinder ShunTool

2024年4月13日 Cleaning the Grinder: If you're using power tools like a grinder, it's crucial to clean them thoroughly after each use Grinding can generate a significant amount of dust, which can accumulate in the tool and affect its performance To clean the grinder, unplug it from the power source and remove any debris or dust using a brush or compressed air2021年10月12日 Using a concrete grinder: Technique matters When grinding concrete, take your time and allow the machine to do its work If you move too fast, odds are you’ll end up redoing some areas Browse United Rentals’ full lineup of How to Grind Concrete Using a Concrete Grinder United RentalsSelections include concrete grinders, also known as a planers, milling machines and rotary cutters, ideal for grinding concrete to leave it smooth and level For our full list of concrete grinders planers, view the items below For more Concrete Grinders, Planers and Scarifiers for RentThe angle grinder is an excellent choice for several reasons: it is small, mobile, versatile, and inexpensive – meaning it may just be the best tool to assist you with your concrete grinding project In this article, we’ll go over: The tools that are required for this project; A stepbystep guide to grinding concrete with angle grinderGrinding Concrete with Angle Grinder: Steps for a Smooth Finish

Cement Grinding Cement Plant Optimization

Grinding aids also serve to reduce coating problems in cement storage and enhances cement strengths GRINDING MILLS Mills will be selected according to type most suitable for required capacity and duty and for overall power consumption Cement grinding operation may be performed in one of the following mill setups Ball and tube millsThe MAXIMUM Masonry Grinding Disc is designed for grinding down most common types of masonry, including concrete, block, limestone, sandstone, and tile This multipurpose wheel is constructed from resinoid bonded with aMAXIMUM Type 28 Carbide Grinding Wheel/Disc for Masonry, Cement1500W 125mm Concrete Grinder $31000 The FULL BOAR 125mm 1500W Concrete Grinder is designed for grinding, levelling, cleaning and finishing concrete surfacesThe high powered 1500W motor delivers superior power and torque while the variable speed and ergonomic DHandle ensures efficient grinding on various surfaces such as concrete, brick and 1500W 125mm Concrete Grinder Full Boar SiteIdo Finished grinding may consume 25 – 50 kWh/t cement, depending on the feed material grindability, additives used, plant design especially the required cement fineness Cement grinding is the single biggest consumer of electricity in the manufacturing process Whichever the mill types, grinding is inherently inefficientImprovements in New Existing Cement Grinding Mills by Tim

Full Boar 2000W 180mm Concrete Grinder Bunnings Australia

The Full Boar 180mm 2000W Concrete Grinder is designed for grinding, levelling, cleaning and finishing of concrete surfaces The highpowered 2000W motor delivers superior power and torque plus the soft grip rear handle and support handle ensures efficient grinding on various surfaces such as concrete, brick and tileCement Grinding Guide Free download as Word Doc (doc), PDF File (pdf), Text File (txt) or read online for free This document discusses operating cement grinding processes efficiently It covers factors that influence grinding efficiency like product fineness, grindability of raw materials, and process parameters Product fineness is important for cement strength and can be Cement Grinding Guide PDF Mill (Grinding) Scribd