4 25 Grinding production line foundation

Grinding powder production line: Process configuration and flow

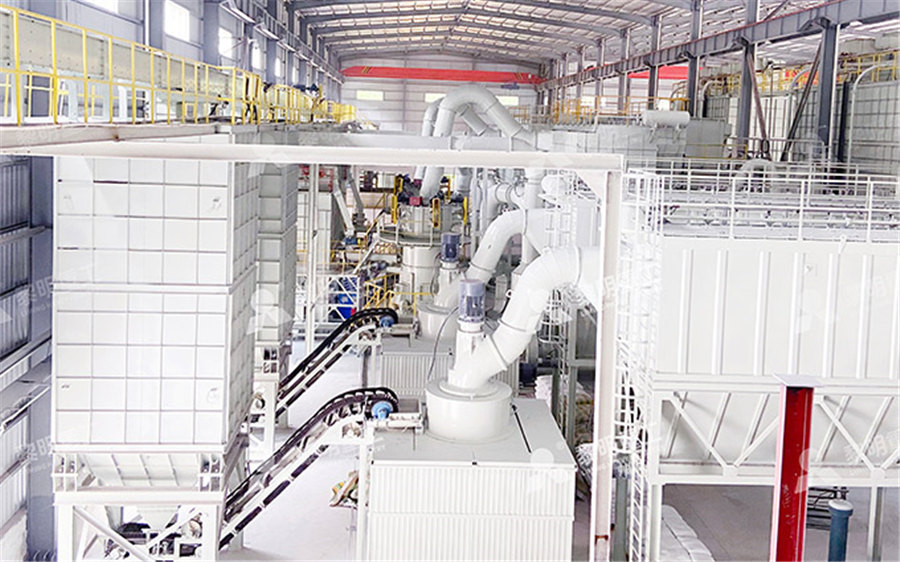

The grinding powder production line is a complex system that requires careful planning and execution to ensure the production of highquality powders The configuration and flow of the Designing a grinding plant to facilitate maintenance activities such as relining provides an excellent return on investment Not only are the relining times reduced which increases mill DESIGNING GRINDING PLANTS FOR MILL RELINING TO MAXIMISE manufacturing production process to grind raw materials (the quadropol QMR²), coal (QMK²) and, increasingly, binding agents or slag (QMC²/QMS²) To ensure the required product fineness for VERTICAL ROLLER MILLS A holistic VRM approach2021年7月12日 This article introduces an expert system to enhance the design of the grinding process A pilot system was built considering three main grinding outputs, including surface Development of an expert system for optimal design of the

Grinding Mill Foundations

2014年9月23日 Most of our work since 2000 has been in developing grinding mill foundations to avoid vibration and unacceptable deflections On a recent project for a plant in Peru, the client A technical reliable solution within the production process includes our sepol® high efficiency separator to ensure the desired product fineness for all applications For raw grinding our new quadropol® thyssenkrupp Polysius Grinding TechnologiesOUR GRINDING CRUSHING COMPETENCE The extensive knowhow of our highly qualified engineers creates a solid foundation for the engineering and construction of such equipment GRINDING TECHNOLOGY TAKRAF GmbH4 CEMENT 4 SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can SikaGrind® for vertical roller mills

.jpg)

5Ply Corrugated Board Production Line Eureka

Machine type: 5ply corrugated production line incl corrugated making slitting and cutting Working width: 1800 mm Flute type: A,C,B,E Top paper index:100 180 gsm Core paper index 80160 gsm In paper index 90160 gsm Running 2019年10月29日 Step 4: Implementation of the new aggregate production line When install ing a new production line every step has to be taken at the right time and in the right way However thorough, our audits can’t uncover every Five steps to implementing a new aggregate Home / Rebar Threading Machine / Rebar Threading Equipment And Grinding Production Line 25: 28: 32: 38: 40 (pieces) 13: 10: 8: 5: 3: 3: 1: 1: Equipped with cuttingedge rib stripping and thread rolling size induction technology, the Rebar Threading Equipment And Grinding Production 2023年10月27日 A scientific and reasonable design for the production line of dolomite processing is the foundation for ensuring high production operation and user benefits Therefore, the equipment of the production line should be arranged compactly and scientifically, with appropriate connections between various links such as crushing and grindingDolomite Sand Making Plant And Grinding Machine

.jpg)

Silicon Wafer Production SpringerLink

2023年8月3日 Silicon already reacts with oxygen at room temperature to form SiO 2, the silicon dioxideSiO 2 is a highquality, mechanically and electrically stable insulator that can be selectively and reproducibly applied to the semiconductor employing temperature treatments This “speciesspecific” oxide is particularly advantageous for electrical insulation and local masking OASIS 5inch 125x60x2223 abrasives grinding wheel production line for metal steel Ready to Ship $030 $036 Min Order: 20000 pieces 11 yrs CN SupplierGrinding wheel production line2013年4月16日 SAG Mill Success—Start with the Basics – WOMP – World of SAG Mill Success —Start with the for overall design of the motor, mill and foundation to any one specific entity, they do offer specific guidelines for » More detailed Choosing a SAG Mill to Achieve Design Performance Key Words: SAG mill, design, optimum conditions, grinding, pilot testing sag mill foundation design criteria Grinding Mill China2024年3月12日 Grinding machines use rotating, abrasive wheels that take light cuts — not so much for high material removal, but to create a better surface finish than can be achieved by milling or turning operations Grinding is commonly one of the last machining operations performed to complete a partGrinding for Precision Machining Production Machining

.jpg)

auto casting grinding balls/ mill balls/ grinding media production line

2022年5月17日 The grinding balls production line adopts sandlined metal mold technology to achieve a chilling process to produce a better quality of the grinding ballsIfFlexible peripheral grinding, thanks to the 6axis kinematics With highperformance technology, COMPACT LINE scores in the flexible machining of indexable inserts As a result of the optional C axis, the machine is also optimally equipped for flexible and efficient peripheral grinding and grinding the Kland protective chamfersCOMPACT LINE2023年3月15日 ① HGM ultrafine grinding mill: 745 micron (2002500 mesh); D97=5 micron HGM series ultrafine mill has superior performance, stable quality, simple operation and convenient maintenance It can be adjusted arbitrarily to Serpentine crushing and grinding processing 4 A flat grinding production line according to claim 1, 2 or 3, characterized in that when the temporary storage panel (920) is located above the positioning panel (940), a distance is preset between the end surfaces of the temporary storage panel (920) Flat grinding processing production line Google Patents

Solved 1 A production line has a series of 4 machines Chegg

A production line has a series of 4 machines namely Lathe, Drilling, Shaping and Grinding The operation time of each machine is 10, 5, 8, and 12 minutes respectively Consider a 5hour production shift per day without any break and breakdowns What is the production rate per day? 60 30 40 25 45 (60 is not correct so please give me otherCutting wheel production line guide Cutting wheel production line guide: English; Türkçe; 2223, 254, 3175mm 222, 254mm 164, 222mm 4 Production process The grinding wheels are manufactured by the hotpress method, in which a mixture of components is pressed into shape at room temperatureCutting Wheel Production Line Guide iSharp Abrasives Tools 2020年11月5日 Industry 40—a term that refers to the digital transformation of manufacturing, business, and society—ushers in the fourth industrial revolution where advances in technology combine the physical, digital, and biological worlds, The foundation for this modern industrial revolution is the Industrial Internet of Things (IIoT), which enables continuous data Promote InProcess Measurement Technology Application in Intelligent FRANLI has several sets of wet grinding production lines, including PCB ink production line, ink production line, pesticide production line, automobile coating production line, etcProduction Line Franli Machine

Copper ore flotation plant optimizes grinding and grading

2024年9月25日 A copper ore selection plant encountered problems during the production and commissioning phaseThe design production capacity of the selected plant is 4500t/d, and the processing capacity is 1875t/h at Taiwan timeIn the early stage of commissioning, when the processing capacity of the ball mill was 140t/h, the indicators were better, but when the Slag grinding mill slag production line INQUIRY CHAT NOW AGICO Slag Mill Parameters At present, vertical roller mill occupies an absolute advantage in slag mill equipment and is the first choice of GGBS production line 23~25: : AGRM223: 2600: 2200: 710: Application of GGBS Production Line Slag Mill for Slag Powder Grinding AGICOGrinding Grinding Software The PROFILE LINE is the grinding center for efficient production of highly complex interchangeable cutting insert geometries, ideally made of presintered tungsten carbide blanks The machine’s high efficiency, coupled with its autonomous multishift operation, is ensured by the smart integrated flexible FANUC 6axisPROFILE LINE UNITED GRINDING2018年1月1日 Simulation for grinding balls production using sand moldgravity casting 254 4 Mineral Application of sandlined metal mold casting technique to grinding ball production lineSimulation for grinding balls production using sand mold

.jpg)

The Introduction of A Whole Gypsum Powder Production Line

1 Introduction of gypsum powder production line Gypsum is a versatile material that is indispensable in the field of industrial construction The gypsum powder production line is obtained by grinding natural dehydrate gypsum ore (raw gypsum) or industrial byproduct gypsum (desulfurization gypsum, phosphogypsum, etc) through a special mill and heating and 2009年6月1日 When the walls are more than 1/2 inch out of level, the foundation contractor typically should take care of the problem, either by grinding down the high spots or filling in the low spots Grinding down high spots isn’t Mudsills and OutofLevel Foundations JLC Online2023年8月1日 This content was downloaded from IP address 91132186213 on 18/08/2023 at 01:18Automatic Cooperative Robot Intelligent Production 2021年1月5日 The new facility will enhance the company’s production capacity from 3 mtpa to 44 mtpa at Sindri The foundation stone for phaseII of Sindri grinding unit was laid in December 2019 with an aim ACC starts production at phase 2 of Sindri grinding unit

.jpg)

INSERT LINE UNITED GRINDING

Highspeed peripheral grinding machine for volume indexable insert production INSERT LINE Key parameters The INSERT LINE is a 4axis highspeed peripheral grinding machine for volume production of indexable inserts at the highest speeds It grinds indexable inserts made of hard materials from 3 mm inscribed circle to max 75 mm circum2019年7月2日 Brake Pads Assembling Production Line Combined Grinding MachinePlease find us at: bullbrakes; : frank@bullbrakes; Mobile/Wechat/Whatsapp: 00Brake Pads Assembling Production Line Combined Grinding The grinding powder production line also includes auxiliary equipment to support the main processing stages This can include feeders, conveyors, silos, and other material handling equipment 5 Process Configuration and Flow The configuration of the grinding powder production line is designed based on the specific requirements of the end productGrinding powder production line: Process configuration and flowA production line has a series of 4 machines namely Lathe, Drilling, Shaping and Grinding The operation time of each machine is 10, 5, 8, and 12 minutes respectively Consider a 5 hour production shift per day without any break and breakdowns What is Solved A production line has a series of 4 machines namely

.jpg)

GRP Production Technology Technobell Technology

As industry experts with over 30 years of experience in GRP production technology, we provide cuttingedge solutions for GRP pipe production Find everything you need to become a successful GRP pipe producer, ensure a quick ROI with our highperforming equipment and advanced knowhow, and benefit from our constant commitment to development for sustained longterm Ball mill production line is mainly consisted of ball mill, hopper, feeder, conveyor, bucket elevator, powder classifier, dust collector and other associated equipments, we can make different design according to customers requirementsJoyalBall Mill Production Line,Ball Mill Production Line For Machine type: 5ply corrugated production line incl corrugated making slitting and cutting Working width: 1800 mm Flute type: A,C,B,E Top paper index:100 180 gsm Core paper index 80160 gsm In paper index 90160 gsm Running 5Ply Corrugated Board Production Line Eureka 2019年10月29日 Step 4: Implementation of the new aggregate production line When install ing a new production line every step has to be taken at the right time and in the right way However thorough, our audits can’t uncover every Five steps to implementing a new aggregate

Rebar Threading Equipment And Grinding Production

Home / Rebar Threading Machine / Rebar Threading Equipment And Grinding Production Line 25: 28: 32: 38: 40 (pieces) 13: 10: 8: 5: 3: 3: 1: 1: Equipped with cuttingedge rib stripping and thread rolling size induction technology, the 2023年10月27日 A scientific and reasonable design for the production line of dolomite processing is the foundation for ensuring high production operation and user benefits Therefore, the equipment of the production line should be arranged compactly and scientifically, with appropriate connections between various links such as crushing and grindingDolomite Sand Making Plant And Grinding Machine2023年8月3日 Silicon already reacts with oxygen at room temperature to form SiO 2, the silicon dioxideSiO 2 is a highquality, mechanically and electrically stable insulator that can be selectively and reproducibly applied to the semiconductor employing temperature treatments This “speciesspecific” oxide is particularly advantageous for electrical insulation and local masking Silicon Wafer Production SpringerLinkOASIS 5inch 125x60x2223 abrasives grinding wheel production line for metal steel Ready to Ship $030 $036 Min Order: 20000 pieces 11 yrs CN SupplierGrinding wheel production line

.jpg)

sag mill foundation design criteria Grinding Mill China

2013年4月16日 SAG Mill Success—Start with the Basics – WOMP – World of SAG Mill Success —Start with the for overall design of the motor, mill and foundation to any one specific entity, they do offer specific guidelines for » More detailed Choosing a SAG Mill to Achieve Design Performance Key Words: SAG mill, design, optimum conditions, grinding, pilot testing 2024年3月12日 Grinding machines use rotating, abrasive wheels that take light cuts — not so much for high material removal, but to create a better surface finish than can be achieved by milling or turning operations Grinding is commonly one of the last machining operations performed to complete a partGrinding for Precision Machining Production Machining2022年5月17日 The grinding balls production line adopts sandlined metal mold technology to achieve a chilling process to produce a better quality of the grinding ballsIfauto casting grinding balls/ mill balls/ grinding media production line Flexible peripheral grinding, thanks to the 6axis kinematics With highperformance technology, COMPACT LINE scores in the flexible machining of indexable inserts As a result of the optional C axis, the machine is also optimally equipped for flexible and efficient peripheral grinding and grinding the Kland protective chamfersCOMPACT LINE