pregrinding equipment

Pregrinding System (CKP mill)

Pregrinding system with CKP vertical type mill is applied for increasing capacity and reducing power consumption of existing ball mill grinding system The capacity can be increased up to double (100%) Also CKP mill achieves Increase product capacity, save energy, shorten production time and ensure reproducibility all this is possible with the new ProPhi pregrinding unit from NETZSCH This new technology improves your dispersion process so that all PreGrinding Mill ProPhi NETZSCH GrindingThe first grinding step for accurate sample preparation is pregrinding the material to remove irregularieties like mounted edges and to produce the required planar surface The Belt PreGrinding Machines for Sample Preparation – ATM Qness GmbHOur marketleading digital ink manufacturing solutions combine revolutionary MacroMedia predispersing and MicroMedia+ fine grinding to create superior inkjet and digital UV inks All of our solutions can be tailored to your precise Wet Grinding and Dispersing Equipment Bühler Group

.jpg)

M2 Metallographic sample pregrinding machine

Taking advantage of various waterproof abrasive sand paper with different granularity, it can be used to pregrind various metal and alloy materials 3 By using this machine, manual grinding Main features of M1 single disc metallographic pre grinding machine: in the process of metallographic sample preparation, sample pre grinding is an essential previous process before polishing After pre polishing the sample, the Pregrinding machine M1 Laizhou Lailuote TestSave huge money by pregrinding your carbide blanks The machine design, optimized by means of state of the art simulation and analysis tools provide solidity throughout the machining centerCarbide blank pregrinding ProfimachPregrinding in an agitator bead mill is many times more efficient and effective than predispersion with a highspeed dissolver, a rotor/stator system or a colloid mill The result is a reduction in NETZSCH P Pregrinding Unit

M1 Type Metallographic Pregrinding Machine

This machine is a singlecontrol constantspeed grinding machine, featuring smooth rotation, safety and reliability, compact structure, and low noise It is equipped with a water cooling Afrimart is the best supplier of Grinding Equipment, We import them directly from manufacturer, warranty for Grinding Equipment is guaranteed B21, Most Products Are Available Under PreOrder Leading time is 35 TO 60 days Filter Menu Sort By : Number: Universal Grinding Equipment Afrimart OnlineExplore concrete equipment: industrial dust extractors, concrete grinders, scarifiers for trip hazard removal, Bull PreSeperator; Slurry Vacs Menu Toggle Bull 160 SVP; Burnishers Menu Toggle HSB 2700; Corner Grinding Polishing Pads; 2″ Diamond Tooling Menu Toggle QuikCut 2″ Hybrid Diamond Tooling;Concrete Equipment Grinders, Scarifiers, Floor Scrapers SASE Why install Roller Press in Cement Manufacturing Plant The overall trend is to increase the capacity of pregrinding bed, and transfer 60% to 70% of of the ball mill functions section to it and high fine airflow classification equipment to Roller Press Install For PreGrinding Before Cement

Bead Mill, Basket Mill, Homogenizer Suppliers, Manufacturers ELE

Shanghai ELE Mechanical and Electrical Equipment Co,Ltd: Welcome to wholesale costefficient bead mill, basket mill, homogenizer, mixer and powder mixing machine for sale here from professional manufacturers and suppliers For price consultation, contact us nowThe first grinding step for accurate sample preparation is pregrinding the material to remove irregularieties like mounted edges and to produce the required planar surface The Belt Grinder Qgrind 100 is ideally suited for manual deburring and pregrinding of materialsPreGrinding Machines for Sample Preparation – ATM Qness GmbHEffective pregrinding is the key to increased performance in raw meal grinding Optimal work distribution within the grinding system “ball mill – classifier – hammer mill” enables operating the plant at a significantly lower specific energy consumption – Pregrinding – PMTThe twostage grinding system composed of a ball mill and a pregrinding roller press or vertical mill and the vertical roller mill final grinding system are the most mature and widely used grinding the selection of appropriate grinding systems and grinding equipment is very important to produce highquality cement Phone: +86 Cement Grinding Plant Expert Cement Grinding Solutions from

Qgrind XL PreGrinder Grinding / Polishing / Etching QATM

When planar grinding metallographic samples, both high removal rates and flat samples with high surface quality are the goals In the „roughing“ grinding mode, material removal can be increased by up to 20% compared to conventional processes, thus significantly reducing process timesThe twostage grinding system composed of a ball mill and a pregrinding roller press or vertical mill and the vertical roller mill final grinding system are the most mature and widely used grinding the selection of appropriate grinding systems and grinding equipment is very important to produce highquality cement Phone: +86 Cement Grinding Plant Expert Cement Grinding Solutions from Heavyduty industrial Shredding Grinding built for demanding recycling operations Discover ECO Green Equipment's machinery for various recycling applications +1 (801) 5056841Shredding Grinding Eco Green Equipment2024年6月15日 Grinding surface quality is a key indicator to determine the performance of parts and the reliability of products During the grinding process, the precontrol technology makes appropriate adjustments in advance on its key aspects to improve the grinding surface quality Therefore, this paper constructs a datadriven precontrol system for grinding surface quality Precontrol of grinding surface quality by datadriven: a review

.jpg)

Advantages of PostGrind system over PreGrind Lark

Also, no separate operators are required for the grinding process as grinding operation is an integrated part of the total feed preparation While in the pregrind system we need extra material handling equipment for powder ingredients which increases the project running cost 2Grinding equipment Production line EP/EPC Spare parts 1,200,000ton per year cement grinding station with pregrinding vertical roller mill ball mill Rotary kiln for foreign project site Waste incineration rotary kiln 800,000ton per year red mud rotary kilnJiangsu Pengfei Group Co,LtdGEA Hole Plates, Knives and Precutters Clear cut, minimum temperature increase, high productivity and lowest possible wear: GEA spare part and tooling portfolio can safeguard the performance of your grinding and emulsifying equipment day in day outPrecutters, hole plates and knives for GEA food grinding equipmentIn this way, the power consumption of the cement mill is reduced and the particle size of cement products is concentrated in the range of 332μm Cement roller press is a kind of pregrinding equipment commonly used in cement grinding plantsMaking Your Cement Grinding Plant Energy Saving Cement Grinding

R)8OC`6F[ZIB.jpg)

Nifty Bar Grinding Cutting Solutions

An Upstate New York manufacturing leader since 1978, Nifty Bar delivers high precision grinding and cutting solutions Skip to Main Navigation Skip to Content 8775365210 5853810450 5853814712Subsystems in Cement PreGrinding Section: A Case Study Approach 1 Introduction Today’s cement manufacturing firms face unin tended machine downtimes and high maintenance costs, landing to a struggle to sustain their market shares The quality and output of grinding and milling operations greatly depend on the availability andMaintenance Performance Optimization for Critical Subsystems in This reduces capital equipment investment costs HEDG can be used on long part lengths and removes material at a rate of 1 in 3 (16 cm 3) in 83 s Pregrinding: when a new tool has been built and has been heattreated, it is preground before welding or hardfacing commencesGrinding (abrasive cutting) WikipediaPreOwned Food Processing Packaging Equipment Welcome to AI Equipment: Used Processing Equipment We deal in used Processing Equipment for wet processing and dry processing and product handling Our main area of expertise is used processing equipment for food products, primarily grain based foods, but we also sell conveying and storage equipment A I Equipment PreOwned Food Processing Packaging Equipment

MSE PRO Speed Adjustable Metallographic Samples Pregrinding

MSE PRO™ Speed Adjustable Metallographic Samples Pregrinding Machine MSE Supplies offers a High Efficiency Metallographic Pre Mill Machine to help you simplify and speed up the The equipment uses cooling water when grinding, which is dustfree and avoids burning hands The equipment comes with a diamond correction pen When the DESCRIPTION The Wiener type Nibrotom is designed especially for the pregrinding of cocoa nibs, nuts, This in turn ensures the best possible performance of all downstream refining equipment Video Technical Data Cocoa Prerefining Grinding Beater Blade MillBuy Metallographic Samples Pregrinding Machine with the best value at MSE Supplies, trusted by 20,000+ scientists and engineers worldwide This grinding machine can also be used for grinding spectral samples The equipment is MSE PRO Metallographic Samples Pregrinding 2006年11月1日 The specific energy consumptions of the grinding equipment and the standard bond work indexes, used 100μm screen, of raw materials are given belowCircuitBond work index (kWh/t)Specific energy (PDF) Pregrinding technology ResearchGate

.jpg)

PreGrinding Mill ProPhi NETZSCH Grinding Dispersing

Highly Efficient Process Engineering Pregrinding in an agitator bead mill is many times more efficient and effective than predispersion with a highspeed dissolver, a rotor/stator system or a colloid mill The result is a reduction in particle size by a factor of 10 15 with the same expenditure of time and with comparable energy input With the new revolutionary ProPhi pre Over the years, ELE has provided thousands of equipment and solutions in the field of paint mixing equipment, ink machinery, dye equipment, oilwater emulsion, etc, In addition, ELE gives technical superiority among the area of tine machining, petrochemical industry, nano materials, Biomedical, food industry, daily health product, agricultural chemical, etcAbout Us Shanghai ELE Mechanical and Electrical Equipment CoWe offer a range of the best pre roll machines for any sized farm or industrial preroll production line, from joint rolling machines to automated preroll filling machines Our selection includes a tabletop industrial cannabis grinder with precise grinding to specific particle sizes, industrial cone packing machines and King Kone style joint rolling machinesPre Roll Machines Custom Cones USAThe pregrinding enhances greatly the efficiency of the sample preparation YM2A is designed according to the customers’ requests and adapted to various kinds of materials The size of the disc and the transmission power are larger than the same products in the market, which is the ideal equipment for pregrindingYM2A Metallographic Sample PregrinderShanghai Metallurgical

.jpg)

EnergyEfficient Technologies in Cement Grinding IntechOpen

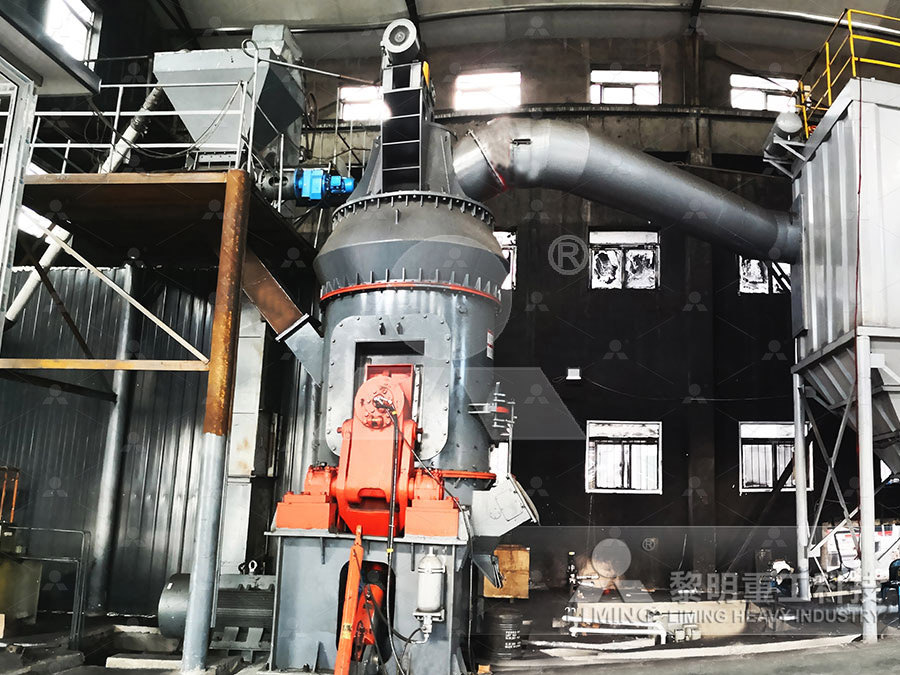

2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a Equipment in cement grinding plant The cement grinding machine includes cement vertical mill, cement ball mill, cement roller press, cement seperator, conveyor and other cement equipmentWe can provide scheme design for free according to the requirements of users, and offer appropriate equipment to ensure smooth production with less investment and high profitcement grinding UnitTogether with ball mill, it can form a circulatory pregrinding system, circulatory hierarchical pregrinding system and fini rotating rollers with pressureVertical pregrinding mill, Vertical roller mill, Grinding equipment Afrimart is the best supplier of Grinding Equipment, We import them directly from manufacturer, warranty for Grinding Equipment is guaranteed B21, Most Products Are Available Under PreOrder Leading time is 35 TO 60 days Filter Menu Sort By : Number: Universal Grinding Equipment Afrimart Online

Concrete Equipment Grinders, Scarifiers, Floor Scrapers SASE

Explore concrete equipment: industrial dust extractors, concrete grinders, scarifiers for trip hazard removal, Bull PreSeperator; Slurry Vacs Menu Toggle Bull 160 SVP; Burnishers Menu Toggle HSB 2700; Corner Grinding Polishing Pads; 2″ Diamond Tooling Menu Toggle QuikCut 2″ Hybrid Diamond Tooling;Why install Roller Press in Cement Manufacturing Plant The overall trend is to increase the capacity of pregrinding bed, and transfer 60% to 70% of of the ball mill functions section to it and high fine airflow classification equipment to Roller Press Install For PreGrinding Before Cement Shanghai ELE Mechanical and Electrical Equipment Co,Ltd: Welcome to wholesale costefficient bead mill, basket mill, homogenizer, mixer and powder mixing machine for sale here from professional manufacturers and suppliers For price consultation, contact us nowBead Mill, Basket Mill, Homogenizer Suppliers, Manufacturers ELEThe first grinding step for accurate sample preparation is pregrinding the material to remove irregularieties like mounted edges and to produce the required planar surface The Belt Grinder Qgrind 100 is ideally suited for manual deburring and pregrinding of materialsPreGrinding Machines for Sample Preparation – ATM Qness GmbH

Pregrinding – PMT

Effective pregrinding is the key to increased performance in raw meal grinding Optimal work distribution within the grinding system “ball mill – classifier – hammer mill” enables operating the plant at a significantly lower specific energy consumption – The twostage grinding system composed of a ball mill and a pregrinding roller press or vertical mill and the vertical roller mill final grinding system are the most mature and widely used grinding the selection of appropriate grinding systems and grinding equipment is very important to produce highquality cement Phone: +86 Cement Grinding Plant Expert Cement Grinding Solutions from When planar grinding metallographic samples, both high removal rates and flat samples with high surface quality are the goals In the „roughing“ grinding mode, material removal can be increased by up to 20% compared to conventional processes, thus significantly reducing process timesQgrind XL PreGrinder Grinding / Polishing / Etching QATMThe twostage grinding system composed of a ball mill and a pregrinding roller press or vertical mill and the vertical roller mill final grinding system are the most mature and widely used grinding the selection of appropriate grinding systems and grinding equipment is very important to produce highquality cement Phone: +86 Cement Grinding Plant Expert Cement Grinding Solutions from

.jpg)

Shredding Grinding Eco Green Equipment

Heavyduty industrial Shredding Grinding built for demanding recycling operations Discover ECO Green Equipment's machinery for various recycling applications +1 (801) 5056841