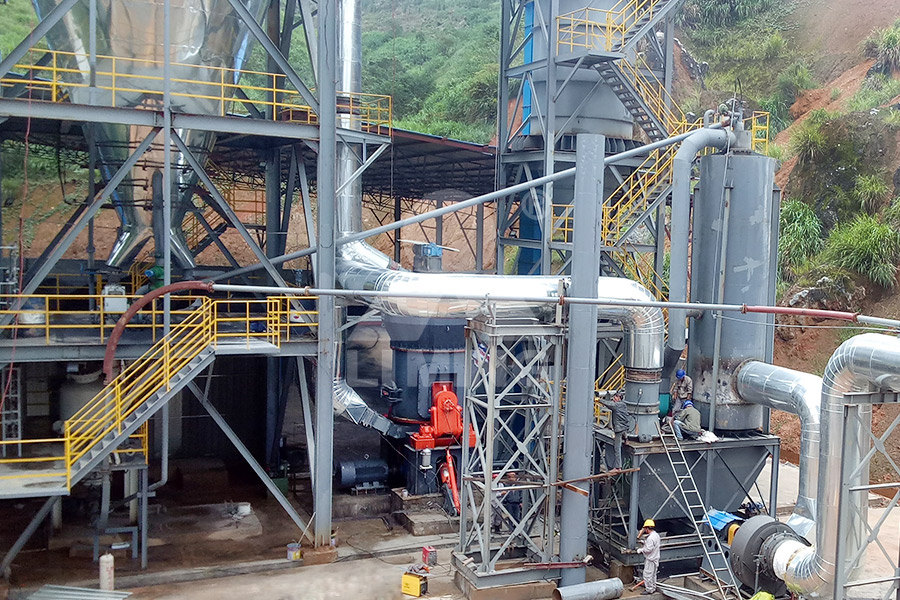

95 tons of calcium carbonate anthracite crushing station

.jpg)

Maximising the benefits of calcium carbonate in sustainable

2024年1月19日 To maximise the benefits of calcium carbonate derived from alkaline waste carbonation in sustainable cements, we have demonstrated that: (i) different forms of calcium CSC carbonation during the curing of concrete occurs extremely rapidly Full hardness in CSCbased concretes can be achieved within 24 hours, during which CO 2 is permanently and Environmental Impact of Carbonated Calcium Silicate Cement 2022年8月26日 Decarbonizing calcium carbonate (CaCO 3) is a crucial step for a wide range of major industrial processes and materials, including Portland cement (PC) production Apart Effect of Impurities on the Decarbonization of Calcium Carbonate 2024年10月5日 The cradletogate LCA focuses on an industrialscale scenario for capturing 200 kilotonnes of CO 2 annually, with functional unit per tonne of carbonated RCA output The Assessing Carbon Capture and Carbonation in Recycled Concrete

Evaluating the Carbon Footprint of Cement Plants Integrated With

2022年4月4日 In this study, greenhouse gas (GHG) emissions related to two cement production systems with CaL carbon capture are evaluated: the tailend CaL carbon capture and the 2021年5月21日 A novel calcium carbonate cement system that mimics the naturally occurring mineralization process of carbon dioxide to biogenic or geologic calcium carbonate deposits Calcium Carbonate Cement: A Carbon Capture, Utilization, andWith the recognised reactive role of calcium carbonate in PC, there is a growing interest in harnessing various forms of calcium carbonate to enhance the performance of different Maximising the benefits of calcium carbonate in sustainable 2020年4月1日 The conventional process gave 095 ton of net CO 2 emission per ton of nCaCO 3 produced, while the proposed CO 2 utilization process gave 087 ton, resulting in a net CO 2 Technoeconomic and environmental evaluation of nano calcium

.jpg)

Experimental analysis on calcination and carbonation process in

2023年3月28日 Several methods for reducing specific CO 2 emissions have been reported in the cement industry, including calcium looping, which uses the reversible reaction between 2022年3月1日 The increase in elastic modulus and carbonation shrinkage both favor microcraking: an increase in macroporosity and permeability is actually observed Clogging Accelerated carbonation of recycled concrete aggregates: The mobile crushing station, mounted on wheels or tracks, can do mobile crushing or portable crushing between sites to form an efficient crushing and screening plant It can be used for coarse, medium, fine crushing or sand A Catalog of All Mobile Crushing Station Fote 2020年4月1日 The results of the SEM test on calcium carbonate (CaCO3) with 50000 times magnification are shown in Figure 2 showing the irregular surface morphology of the particle [18](PDF) Physicochemical Determination of Calcium

APEX Factory Facilities Calcium Carbonate and

The pride of Apex lies in its factory facilities, representing the pillars of its exceptional productivity These stateoftheart facilities are equipped with advanced machinery to meet a diverse range of customer needs Whether for 2020年11月26日 with more than 95% CO 2 96,000 tons of calcium carbonate per year, which will generate an income of around 10 million euro per crushing, milling, and leaching [74](PDF) Utilization of Gaseous Carbon Dioxide and Industrial CaRich as a specialized in the exploitation and export of Calcium Carbonate products, we are proud to own one of the largest quarries sites in Minya quarry area, Minya governorate, Egypt With a reserve of more than 15 million tons of white limestone, Our average extraction capacity is estimated to be 200,000 tons annuallyAbout Al Rabie Group Calcium Carbonate2022年3月8日 Calcium Carbonate (CaCO3) is found in limestone, CO2 emissions are produced by cement industries, and cement production is projected to exceed 6 billion metric tons by 2050 These facts are a cause for global concern In response, the cement industry utilizes Supplementary Cementing Material Calcium Carbonate in the Concrete Industry Noah Chemicals

.jpg)

From waste to commodity: transforming shells into high purity calcium

2009年2月1日 calcium carbonate, accounts for 95–99% by weight its production in 2005 was 204796 tons of calcium carbonate product, while in 2006 1 yielding precipitated calcium carbonate 2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses2021年9月14日 Laser diffraction technology is one of several methods currently employed to determine particle size distributions But laser diffraction is the only technology applicable for powders, suspensions (PDF) Measuring the Particle Size Distribution of Calcium Carbonate 2023年12月7日 The equipment used in the manufacturing process for calcium carbonate varies depending on the type of calcium carbonate being produced For natural calcium carbonate, the equipment typically includes crusher, screens, grinder mill, and washers For synthetic calcium carbonate, the equipment typically includes calciners, dissolvers, and carbonatorsWhat is the steps in the Calcium Carbonate Manufacturing

Precipitation of Calcium Carbonate in Aqueous

1984年1月1日 The precipitation of calcium carbonate from aqueous solutions has been studied at supersaturations sufficient for spontaneous precipitation but low enough to enable highly reproducible experiments The selection of calcium carbonate grinding mill will affect the quality of the final ground calcium It is generally mostly primary crushing its output is also different Generally speaking, the annual output of the ball mill is between How to Choose a Calcium Carbonate Grinding Mill2016年8月20日 Soda residue (SR), the solid waste of Na2CO3 produced by ammonia soda process, pollutes water and soil, increasing environmental pressure SR has high alkalinity, and its main components are Ca(OH (PDF) Calcium carbonate synthesis with prescribed 2021年12月28日 Calcium carbonate based filler additive materials have approximately 70% market share in North production rate of over 4,500 tons [1718] nearly 95 0,000 peopl e and supporting over one (PDF) InSitu Precipitated Calcium Carbonate Paper

Calcium Carbonate (Calcite) SpringerLink

2022年4月12日 Limestone is a sedimentary rock comprised chiefly of calcium carbonate (CaCO3) Deposits are extensive around the world Therefore, there is a high variability of limestone deposits Typically, they are formed in two main environments2007年4月1日 The same hydrate phases for both the CEM I 525 R and CEM II/ALL 525 R paste with a w/cratio of 055 were predicted by the thermodynamic model (see Figure 2 Figure 3)The Role of Calcium Carbonate in Cement Hydration2024年1月19日 Maximising the benefits of calcium carbonate in sustainable cements: opportunities and challenges associated with alkaline waste carbonationMaximising the benefits of calcium carbonate in sustainable 2021年9月21日 This study provides an overview of calcium rich industrial wastes usage in construction materials, their properties and different applications through marble waste and flue gas desulfurization (FGD) gypsum Large quantities of industrial wastes are stockpiled and haphazardly disposed in increasing amounts causing serious environmental concerns The A review on calciumrich industrial wastes: a sustainable

(PDF) Application of eggshell wastes as valuable and utilizable

2018年8月8日 PDF Eggshell is a solid waste, with production of several tons per shells are calcium carbonate 2022) Vó trĀng chĀa tĆi 95% canxi cacbonat và nhiều chçt dinh dþĈng đa 2023年3月21日 Highend calcium carbonate production line with an annual output of 300,000 tons in Anhui, China Processing raw material: calcite Finished fineness: 1501250 mesh Annual output: more than 300,000 tons Finished product use: papermaking, coatings, building materialsThe advantages of ultrafine vertical mill in the processing and 2021年10月23日 Calcium carbonatebased shells represent another large group of agro/biowaste The overview of highenergy milling processing of eggshells, As a source of calcium, cuttlefish bone was used, which, after crushing, was calcined at 1300 °C and CaO was formed This powder was then either precipitated or ball milled with Shells and Other Calcium CarbonateBased Waste2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on Precipitated Calcium carbonate production,

AP42, Appendix B2 Generalized Particle Size Distributions

12 Anthracite coal combustion a 87 Hydrofluoric acid (thermal process) a Distillate oil 810 Sulfuric acid b Utility a 812 Sodium carbonate a Commercial a Food and agricultural Residential a 931 Defoliation and harvesting of cotton 14 Natural gas combustion a Coarse crushing 3 Reverberatory furnace a Ore transfer 3 129 Secondary 2023年7月17日 ABSTRACT The calculation of the dissipated thermal energy of mineral crushing is of great significance for the reduction of the heat loss in the crushing process The traditional calculation method is relatively simple, which does not consider practical problems, such as cooling during the crushing process and uneven temperature distribution This paper used Calculation model of dissipated thermal energy of anthracite Download scientific diagram FTIR spectra of calcium carbonate precipitates at different time intervals (A) One day, (B) four days [Ca 2+ ]/[H 4 dhpta] ¼ 4 : 1 The absorption bands at 865 cm FTIR spectra of calcium carbonate precipitates at different 2021年6月22日 The calcium carbonate production line with an annual output of 300,000 tons uses a vertical grinding mill production line to crush, grind, and classify calcium carbonatecontaining minerals such as limestone, marble, chalk, icelandite, stalactite, aragonite, vaterite, and semihydrated calcium carbonate A summary of the production line equipment for a 300,000 tons of calcium carbonate powder production line

Precipitation of calcium carbonate from hydrated lime of variable

2009年9月1日 Besides the quality of the limestone and the conditions of calcination used to produce the CaO, the slaking process is affected by: CaO microstructure, including particle size [24][25][26], pore Calcium Carbonate CaCO3 or CCaO3 CID 10112 structure Calcium carbonate, ACS reagent, chelometric standard, 999510005% dry basis; Calcium carbonate, anhydrous, freeflowing, RediDri(TM The Merck Index An Encyclopedia of Chemicals, Drugs, and Biologicals 13th Edition, Whitehouse Station, NJ: Merck and Co, Inc Calcium Carbonate CaCO3 CID 10112 PubChem2014年5月29日 This was probably due to the force applied during crushing and of iron and calcium oxides (3958–6295%) about 026 tons of CO 2 by forming the calcium carbonate Direct carbonation of red gypsum to produce solid carbonatesPrecipitated calcium carbonate is an in organic chemical obtained by calcining naturally occurring lime stone, slaking and carbonation Precipitated calcium carbonate is pure form of lime stone used in the chemical industries Precipitated calcium carbonate (PPC) is used as filler coating pigment for premium quality paper productsPROFILE ON THE PRODUCTION OF CALCIUM CARBONATE AND

A Catalog of All Mobile Crushing Station Fote

The mobile crushing station, mounted on wheels or tracks, can do mobile crushing or portable crushing between sites to form an efficient crushing and screening plant It can be used for coarse, medium, fine crushing or sand 2020年4月1日 The results of the SEM test on calcium carbonate (CaCO3) with 50000 times magnification are shown in Figure 2 showing the irregular surface morphology of the particle [18](PDF) Physicochemical Determination of Calcium The pride of Apex lies in its factory facilities, representing the pillars of its exceptional productivity These stateoftheart facilities are equipped with advanced machinery to meet a diverse range of customer needs Whether for APEX Factory Facilities Calcium Carbonate and 2020年11月26日 with more than 95% CO 2 96,000 tons of calcium carbonate per year, which will generate an income of around 10 million euro per crushing, milling, and leaching [74](PDF) Utilization of Gaseous Carbon Dioxide and Industrial CaRich

.jpg)

About Al Rabie Group Calcium Carbonate

as a specialized in the exploitation and export of Calcium Carbonate products, we are proud to own one of the largest quarries sites in Minya quarry area, Minya governorate, Egypt With a reserve of more than 15 million tons of white limestone, Our average extraction capacity is estimated to be 200,000 tons annually2022年3月8日 Calcium Carbonate (CaCO3) is found in limestone, CO2 emissions are produced by cement industries, and cement production is projected to exceed 6 billion metric tons by 2050 These facts are a cause for global concern In response, the cement industry utilizes Supplementary Cementing Material Calcium Carbonate in the Concrete Industry Noah Chemicals2009年2月1日 calcium carbonate, accounts for 95–99% by weight its production in 2005 was 204796 tons of calcium carbonate product, while in 2006 1 yielding precipitated calcium carbonate From waste to commodity: transforming shells into high purity calcium 2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses

.jpg)

(PDF) Measuring the Particle Size Distribution of Calcium Carbonate

2021年9月14日 Laser diffraction technology is one of several methods currently employed to determine particle size distributions But laser diffraction is the only technology applicable for powders, suspensions 2023年12月7日 The equipment used in the manufacturing process for calcium carbonate varies depending on the type of calcium carbonate being produced For natural calcium carbonate, the equipment typically includes crusher, screens, grinder mill, and washers For synthetic calcium carbonate, the equipment typically includes calciners, dissolvers, and carbonatorsWhat is the steps in the Calcium Carbonate Manufacturing