How much is a grinding machine for slag mineral grinding machinery

.jpg)

Wholesale Slag Grinding Machine MadeinChina

Wholesale Slag Grinding Machine Select 2024 high quality Wholesale Slag Grinding Machine products in best price from certified Chinese Grinding Machine manufacturers, Steel Machine suppliers, wholesalers and factory on MadeinChinaFind the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale slag grinding machine model and mills for any mining challengeSimple Ore Extraction: Choose A Wholesale slag grinding machine The Mineral Slag Grinder offered by Weifang Jinghua Powder Engineering Equipment Co, Ltd is a highefficiency grinding equipment designed specifically for processing mineral slag This China Mineral Slag Grinder Manufacturer, Supplier JINGHUABrowse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills technology offer exceptional performance and Grinding mills for mining and minerals processing

China Slag Grinding Machine, Slag Grinding Machine Madein

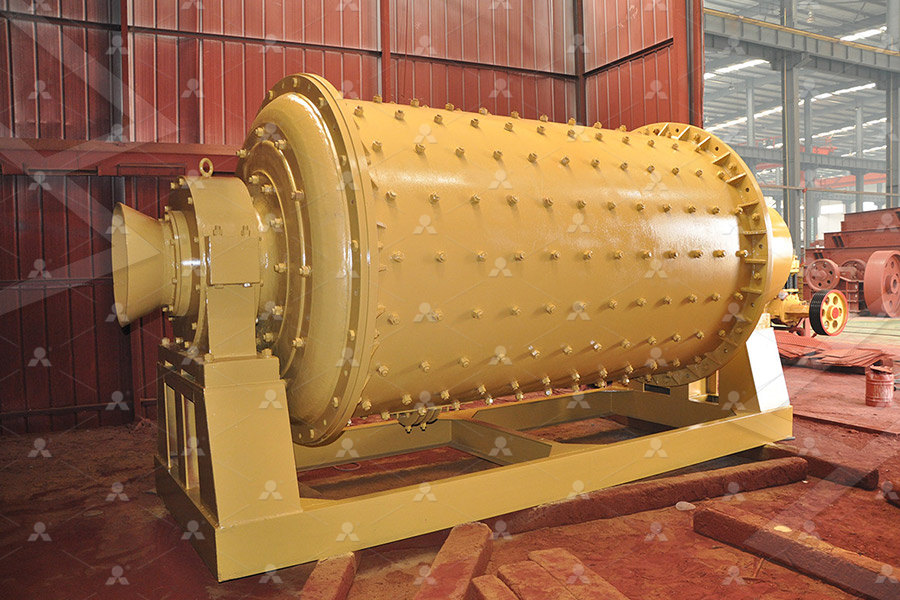

China Slag Grinding Machine wholesale Select 2024 high quality Slag Grinding Machine products in best price from certified Chinese Machine Machinery manufacturers, Machine Experience CuttingEdge Technology with N and T Engitech's Slag Grinding: Your Ideal Solution for IndustrySpecific Thermal Processing Needs Cement Industries RMC PlantSlag Grinding Plant Manufacturers NT EngitechMetso HIGmill™ is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind HIGmill high intensity grinding mill MetsoThe ball milling system is a traditional slag grinding process It has strong adaptability to materials, large specific surface area, better particle shape than vertical mills, simple maintenance, and Slag Grinding line mining processing machine XKJ Group

.png)

GRINDING Grinding options for slag and pozzolan PEC

Grinding options for slag and pozzolan While the use of supplementary cementitious materials is increasingly popular, the use of granulated blastfurnace slag and pozzolans presents extra Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining application Whether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction Industrial Ore, Mineral, Slag Crusher Mineral 2022年12月8日 A CNC grinding machine uses a rotating grinding wheel to remove small amounts of material from a workpiece They are, first and foremost, finishing machines In the case of round work, a machinist often removes CNC Grinding Machine Buyers Guide: Types, Price, 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Energy Use of Fine Grinding in Mineral Processing

.jpg)

Cement Grinding Plant Overview Cement Grinding

2019年10月11日 AGICO Cement is a cement grinding plant manufacturer, we'd like to helps you learn more about cement grinding plant and cement grinding machines Skip to content +86 s Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, live data from various sources and incorporate advanced analytics enriched with machine learning, artificial intelligence, but also considering how your Premier™ or Select™ mill will optimize your minerals processing circuitGrinding mills for mining and minerals processing Metso2024年1月11日 Innovations in grinding wheel materials, such as using cubic boron nitride in CBN grinding wheels, enhance the machine’s ability to grind hard materials while maintaining a flat edge and desired surface quality The development of more efficient and precise grinding machines continues to address the evolving challenges in surface grindingSurface Grinding: A Guide to the Process and Precision okdor2023年4月23日 grinding when using steel grinding media and it is responsible for up to 50% of steel grinding media consumption [75] Mass loss by corrosion is due to oxidative electrochemical reactions The (PDF) Grinding Media in Ball MillsA Review ResearchGate

Slag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill

Mineral powder with a fineness of 400450m2/kg can be used to prepare 425,425R slag Portland cement; mineral powder with a fineness of 450500m2/kg can be prepared with 525,525R slag Portland cement155 results for Grinding Machines in Ghana Location All Ghana Price, GH₵ min max Under 500 • 157 ads 500 3 K • 631 ads 3 20 K • 1 052 ads 20 100 K • 658 ads More than 100 K • 131 ads Clear Save Type Show Grinding Machines in Ghana for sale Price on JijighThey pose the risk of removing too much material from the workpiece Slag grinding: Our slag grinders are the most efficient means to remove slag accumulation Specifically designed for this purpose, they quickly remove any amount of buildup in a single pass Grinding Slag Removal Solutions at Apex Machine GroupGrinding Slag Removal Apex Machine Group2020年1月30日 In a newer way to get rid of the “slag”, Timesavers has introduced its Hammerhead Slag GrinderThe innovative approach to grinding metal involves tiny pins that rotate in the opposite direction of the metal being fed into the machine, which allows for the pins to hit and remove any excess metal that does not belong to the main partWhat is Slag Grinding? — Carlson Fabrication Solutions

Electric Grinding Machines in Nigeria for sale Price on Jijing

Jijing More than 38 Electric Grinding Machines for sale Price starting from ₦ 200,000 in Nigeria choose and buy today! Make betterOUTPUT SIZE: 10mm to 275mm PRODUCTION CAPACITY: 2502000t/h PROCESSED MATERIALS: The CI5X Series Impact Crushers is most suitable for crushing the materials whose crushing strength lower than 320MP like Crushing, Grinding, Mobile Crusher Kefid Shanghai 2013年1月1日 Superb grinding machines now produce optical quality finishes due to developments in process control and machine design It is the same for extremely high removal ratesPrinciples of Modern Grinding TechnologyBouchard J, LeBlanc G, Levesque M, Radziszewski P and GeorgesFilteau D Breaking Down Energy Consumption in Industry Grinding Mills, in Muinonen J, Cameron R and Zinck J (Editors) 49th Annual Canadian Minerals Processors Conference Proceedings, pp 2535, Ottawa, Canada, 2017, Office of the Secretary of the Canadian Mineral Processors, a Technical Society of The Breaking Down Energy Consumption in Industry Grinding Mills

.jpg)

Options for Grinding Slag and Pozzolan for Use as Construction

VRMs have been gaining popularity in new projects as energy consumption can be up to 40 per cent less than that of ball mills, 6 in addition to allowing materials with a higher moisture content than competing grinding systems Many advances in VRM technology have been made for clinker and slag grinding as well as for the production of pozzolanic blended cements 72024年1月23日 Basic Grinding Machines: Entrylevel grinding machines, suitable for smallscale operations or less complex tasks, typically range from $5,000 to $20,000 MidRange Grinding Machines: These machines, offering more features and greater precision, are generally priced between $20,000 and $60,000What is Grinding: Definition, Process, Types SpecificationsJijiug More than 216 Grinding Machines for sale Price starting from USh 55,000 in Uganda choose and buy today! Make betterGrinding Machines in Uganda for sale Price on Jijiug2018年8月9日 Industrial grinding machines are a useful tool when it comes to breaking down different types of materials and is very Grinding machinery can be used to reduce the particulate size of various shale, and slag The tool offers a unique ability to recover highvalue precious metals and industrial minerals that are too Industrial Grinding Machines: How it Works General Kinematics

Powder Grinding Mills Engineered by FTM Fote Machinery

Whether soft rock, hard rock, nonmetallic minerals, or coal, FTM Machinery can provide costeffective grinding solutions Our powder milling machines are particularly suitable for producing clean coal powder, limestone powder, gypsum powder, quartz powder, calcium carbonate powder, marble powder, barite powder, mica powder, and bentonite powder2013年3月1日 Request PDF Energy Use of Fine Grinding in Mineral Processing Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizesEnergy Use of Fine Grinding in Mineral ProcessingWe offer various types of machinery for the removal of very heavy burrs from OxyAcetylene Cutting, Plasma Cutting and Drilling for the removal with or without surface grinding (leave scale on to prevent weld spatter sticking), with or without Slag Grinding GE Machinery Applications for metal finishing2008年3月3日 The use of GGBFS as a partial Portland cement replacement takes advantage of the energy invested in the slagmaking process and its corresponding benefits with respect to the enhanced cementitious properties of the slag Grinding slag for cement replacement requires only about 25% of the energy needed to manufacture normal Portland cementEfficient and reliable handling of GBFS and GGBFS at grinding

.jpg)

Mineral Processing Equipment for Mining Industry

2024年8月7日 Key Considerations for Choosing Mineral Processing Equipment Selecting the right equipment involves evaluating several factors: Mineral Type and Characteristics: The type and properties of the mineral affect equipment 2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and Pulverizers2021年1月16日 Surface Grinder 101: What is a surface grinder and how do grinding machines work? See different types of surface grinders and their uses to pick the best one Skip to content Menu Home; MACHINES; Process; WELDING; Surface Grinder January 17, Surface Grinder Types of Grinders How They Work Fine the particle But for a 9 micron particle this rim is sufficient for the mineral to disintegrate (Figure 2) • The mechanical activation impact the high energy intensity of fine creates a highly stressed surface, reducing the crystalline nature to amorphous phases (Figure 3)Fine Grinding as Enabling Technology – The IsaMill

.jpg)

The Effect of Removing HardtoGrind Minerals from Steel Slag

2023年8月22日 It is found that the removal rate of hardtogrind minerals in steel slag is the highest when steel slag enters magnetic separation particle size of 1 mm and magnetic field strength of 1400 Gs Compared with untreated steel slag, the grinding efficiency of treated steel slag can be increased by 22%, and the hydration activity is not affected2017年7月1日 Crushing Or Grinding Machines: 18: 0: 01/07/2017: 18%: : Machinery For Sorting, Screening, Separating, Washing, Crushing, Grinding, Mixing Or Kneading Earth, Stone, Ores Or Other Mineral Substances, In Solid (Including Powder Or Paste) Form; Machinery For Agglomerating, Shaping Or Moulding Solid Mineral Fuels, 18: 0: 01/07/2017: 18% MACHINERY FOR GRINDING MIXING GST RATES HSN 2016年11月22日 Fundamentals of grinding mechanism As a material removal process, grinding process is similar to other cutting processes in many respects, such as materials are removed in forms of chips (Chen, Citation 2009; Rowe, Citation 2009)However, grinding has its distinctness from other machining processesEffect of different parameters on grinding efficiency and its 2024年8月15日 Comminution involves both crushing and grinding As the first step in mineral processing, Although flotation machines require fine grinding and can be costly, they are efficient and can process most types of ore FTM Machinery has become the first choice for over 2,000,000 customersMineral Processing Plants: What You Need to Know Fote Machinery

.jpg)

CNC Grinding Machine Buyers Guide: Types, Price,

2022年12月8日 A CNC grinding machine uses a rotating grinding wheel to remove small amounts of material from a workpiece They are, first and foremost, finishing machines In the case of round work, a machinist often removes 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Energy Use of Fine Grinding in Mineral Processing2019年10月11日 AGICO Cement is a cement grinding plant manufacturer, we'd like to helps you learn more about cement grinding plant and cement grinding machines Skip to content +86 s Cement Grinding Plant Overview Cement Grinding Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, live data from various sources and incorporate advanced analytics enriched with machine learning, artificial intelligence, but also considering how your Premier™ or Select™ mill will optimize your minerals processing circuitGrinding mills for mining and minerals processing Metso

.jpg)

Surface Grinding: A Guide to the Process and Precision okdor

2024年1月11日 Innovations in grinding wheel materials, such as using cubic boron nitride in CBN grinding wheels, enhance the machine’s ability to grind hard materials while maintaining a flat edge and desired surface quality The development of more efficient and precise grinding machines continues to address the evolving challenges in surface grinding2023年4月23日 grinding when using steel grinding media and it is responsible for up to 50% of steel grinding media consumption [75] Mass loss by corrosion is due to oxidative electrochemical reactions The (PDF) Grinding Media in Ball MillsA Review ResearchGateMineral powder with a fineness of 400450m2/kg can be used to prepare 425,425R slag Portland cement; mineral powder with a fineness of 450500m2/kg can be prepared with 525,525R slag Portland cementSlag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill155 results for Grinding Machines in Ghana Location All Ghana Price, GH₵ min max Under 500 • 157 ads 500 3 K • 631 ads 3 20 K • 1 052 ads 20 100 K • 658 ads More than 100 K • 131 ads Clear Save Type Show Grinding Machines in Ghana for sale Price on Jijigh

Grinding Slag Removal Apex Machine Group

They pose the risk of removing too much material from the workpiece Slag grinding: Our slag grinders are the most efficient means to remove slag accumulation Specifically designed for this purpose, they quickly remove any amount of buildup in a single pass Grinding Slag Removal Solutions at Apex Machine Group2020年1月30日 In a newer way to get rid of the “slag”, Timesavers has introduced its Hammerhead Slag GrinderThe innovative approach to grinding metal involves tiny pins that rotate in the opposite direction of the metal being fed into the machine, which allows for the pins to hit and remove any excess metal that does not belong to the main partWhat is Slag Grinding? — Carlson Fabrication Solutions