Production data of electrolytic manganese plant

Life cycle assessment of electrolytic manganese metal production

2024年11月1日 This study aims to (1) analyze the environmental burden of EMM production in the Manganese Triangle region of China using the LCA method; (2) obtain quantitative results 2016年5月1日 Manganese metal is typically produced by the electrolysis of manganese and ammonium sulfate solution The most commonly used technology involves reductive calcining Electrolytic manganese metal production from manganese 2020年4月1日 Electrolytic manganese anode slime (EMAS) is produced during the production of electrolytic manganese metal In this study, a method based on vacuum carbothermal Life cycle assessment of electrolytic manganese metal production 2012年2月2日 In this paper, based on the practice of manganese production in China, a preliminary life cycle assessment (LCA) of the electrolytic manganese industry is provided, Production assessment in the electrolytic manganese metal

Electrolytic manganese metal production from manganese

2016年5月1日 Abstract Manganese sulfate solution would be affected by various factors in electrolytic production of manganese When different electrolysis time was controlled, the 2020年6月6日 In this paper, the effects of roasting and leaching condition on the leaching recovery of manganese and iron using HSMO as reducing agent were investigated in a A Novel Circulation Process to Effectively Produce Electrolytic China ranks as the fourthlargest producer of manganese ore and the largest producer of electrolytic manganese metal (EMM) However, EMM production is linked to high energy Life cycle assessment of electrolytic manganese metal production2012年2月2日 In this paper, based on the practice of manganese production in China, a preliminary life cycle assessment (LCA) of the electrolytic manganese industry is provided, Production assessment in the electrolytic manganese metal

Electrolytic manganese metal production from manganese

2016年5月1日 The study quantified the environmental performance of electrolytic manganese metal production by conducting a life cycle assessment using the ReCiPe2016 method 2016年5月1日 Sulfur dioxide was first used to produce electrolytic manganese commercially with a reasonable current efficiency (60–65%) The effects of SO 2 are: (1) increasing the overpotential of hydrogen evolution and hence the manganese current efficiency; (2) promoting the formation of stable αmanganese, (3) counteracting the harmful effects of impurities, and (4) suppressing Electrolytic manganese metal production from manganese Use detailed tutorial to learn the stepbystep procedure for starting the manufacturing of electrolytic manganese dioxide (EMD Our experienced professionals will conduct extensive research to gather accurate data and conduct indepth analyses to Analysis of the economics of the plant, including production schedules and How to Start Electrolytic Manganese Dioxide (EMD) Production2019年5月23日 The smelting of manganese ores is mainly performed through electrolysis and reduction to produce pure manganese Electrolysis produces over 95% of total manganese metal products [], and electrolytic manganese (EM) has very high purity and used mainly as deoxidant and desulfurizing agent in iron and steel smelting processesManganese is the element most Resource Utilization of Electrolytic Manganese Residues

.jpg)

Electrolytic Manganese Dioxide (EMD) Industry in India: A

Plant Layout: Details on the plant layout and utility requirements Project at a Glance Our reports provide a snapshot of the project, including: Assumptions for Profitability Workings: Assumptions used in profitability calculations Plant Economics: Analysis of the plant's economics Production Schedule: Detailed production schedulesIt is the starting material for electrolytic manganese metal, electrolytic manganese dioxide, This dataset represents the production of manganese sulfate from manganese concentrate The inventory is based on stoichiometric calculations and approximations based on data from a large chemical plant (Gendorf 2016) References: Reidies, A H 2000manganese sulfate production, UPR, ecoinvent 36, Allocation, 2024年11月1日 This enterprise has a comprehensive EMM production chain encompassing power plants, manganese mines, electrolytic manganese plants, and is the sole industrialscale production line for utilising manganese residue resources worldwide Over the years, the company has contributed approximately 40 % of EMM production worldwideTechnoeconomicenvironmental analysis based on life cycle 1990年1月1日 The National Metallurgical Laboratory, Jamshedpur, India has established a 50kg/day electrolytic manganese dioxide and 50 kg/day electrolytic manganese metal pilot plant Various manganese ores from different parts of India and abroad have been tested in the pilot plant, using various equipment and materials of constructionPILOT PLANT STUDIES FOR THE PRODUCTION OF ELECTROLYTIC MANGANESE

.jpg)

Reuse of furnace fines of ferro alloy in the electrolytic manganese

2006年11月1日 The use of ferroalloy fines, especially the (FeMn) alloy, to replace Rhodocrosite in the production of electrolytic manganese was studied This approach helped to solve the environmental problem Manganese ore used in the production process comes from the Northern Cape Province of South Africa, which is known to contain 75% of the world’s identified manganese ore reserves Plant capacity: The company was established in 2007 when the Renova Group, a Russian diversified investment holding, acquired the plantTransalloys, South Africa International Manganese Institutethat 30`), manganese, the cost of production of electrolytic manganese in India in a 10tonaday plant is not likely to exceed Rs 1,00(1 a ton The work being done at the Laboratory to produce electrolyticbatteryactive manganese dioxide front lowgrade Indian ores, is discussed separately; it is stated that laboElectrolytic Manganese Manganese Dioxide from Lowgrade 2023年3月8日 Electrolytic manganese residue (EMR) is a solid waste produced in the process of electrolytic manganese metal (EMM) production In recent years, the accumulation of EMR has caused increasingly serious environmental problems To better understand the state of EMR recycling in recent years, this paper used a comprehensive literature database to conduct a Progress in comprehensive utilization of electrolytic manganese

.jpg)

Hydrometallurgical Production of Electrolytic

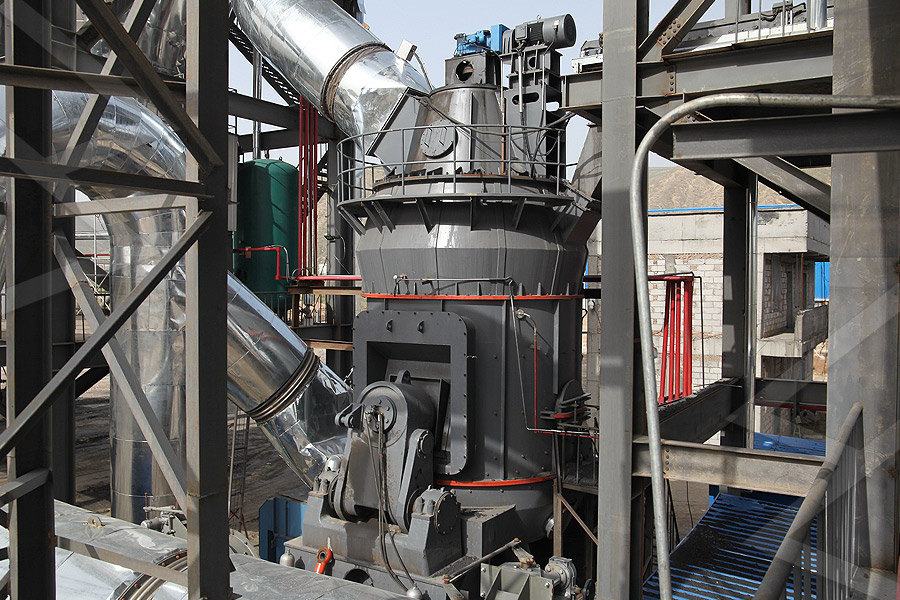

2021年7月1日 The ferromanganese (FeMn) alloy is produced through the smeltingreduction of manganese ores in submerged arc furnaces This process generates large amounts of furnace dust that is environmentally problematic 2016年1月22日 Hence, from the perspective of environmental protection and energysaving, this work adopted solar electrokinetic remediation methods to treat the EMR of an electrolytic manganese plant in Guangxi Electrolytic manganese metal production from manganese 2011年11月1日 Electrolytic manganese metal production process Actual data from these companies show these nonlow cost options at most reduced 10% of Download: Download fullsize image; Fig 3 Operation site in electrolytic manganese metal plant ((a) Passivating cathodes, (b) Discharging filter cake, (c) Residue landfill 23 CP high Electrolytic manganese metal industry experience based 2019年2月19日 Indonesia Tsingshan Stainless Steel (ITSS) on February 13 commissioned its second production line at its manganese plant The company has two manganese production lines in China exported 19,586 mt of electrolytic manganese to Indonesia in 2018, up 67% from 2017, data from China Customs showed The exports were unwrought Growing manganese capacity in Indonesia to shrink China’s

Globally sustainable manganese metal production and use

2009年9月1日 Nonferrous applications of manganese include production of drycell batteries, plant fertilizer components, animal feed and colorant for bricks The manganese ore (high grade 35% manganese) production world wide is about 6 million ton/year and electrolytic manganese metal demand is about 07 million ton/yearThe Deep Dive: Electrolytic Manganese Dioxide (EMD) Manufacturing The Production Process Understanding the intricacies of the EMD production process is essential for anyone considering venturing into this industry At its core, the process involves the electrolytic oxidation of manganese sulfate solutionOpportunities in Electrolytic Manganese Dioxide (EMD) 2021年12月1日 Pyrolusite and rhodochrosite are the two main raw materials used in electrolytic metal manganese (EMM) production [32–37] Manganese can be obtained using aluminothermic [38–42], electrosilicon thermal methods [14,43–45], and electrothermal methods [46–51] The electrolytic method is extensively used in China and South Africa [52,53]Efficient production of metal manganese achieved by cylindrical 2024年1月5日 Electrolytic manganese residues (EMR) and alkaliactivated lateritebased geopolymers were used to prepare slowrelease fertilizers (SRFs) and the physicochemical properties and Mn release behavior of EMRlateritebased SRFs (SRFsLA) were studied MnSO 4 H 2 O in EMR transforms into CaMnSi 2 O 6, MnO 2 and (NH 4) 2 Mn(SO 4) 2 6H 2 O after Preparation of slowrelease fertilizers by electrolytic manganese

Manganese Chemicals Vibrantz Technologies

Nine global production sites; We expertly identify and source raw materials for our mineral and hydrometallurgical plants that produce manganese oxides and salts EMD – Electrolytic manganese dioxide Manganese filter media ® Mn(NO 3) Investigations on production of electrolytic manganese and electrolytic manganese dioxide were initiated in this laboratory in 1950 for the utilisation of lowgrade manganese ores Basic data for the two processes were collected by 1953 and the processes developed were covered by patents Before the processes could be handed over for commercial exploitation, it was thought Production of Manganese and Manganese Dioxide Pilot Plant High Grade Ores for production of Ferro manganese; Medium grade ore for production of Silico manganese; Blast furnace grade ore required for production of hot metal and; Dioxide for dry battery cells and chemical industries MOIL has set up a plant based on indigenous technology to manufacture 1,500 MT per annum capacity of Electrolytic MOIL Limited International Manganese Institute: IMnI2020年4月1日 Therefore, this study incorporates three additional LCIs for the primary production of MnSO 4 from electrolytic manganese metal (EMM), electrolytic manganese dioxide (EMD), and PM nodules Life cycle assessment of electrolytic manganese metal production

Hydrometallurgical Production of Electrolytic Manganese

Electrolytic MnO2 (EMD) Production After almost complete leaching of manganese from the furnace dust, the manganese sulfaterich solution can be used in the production of different end products In this study, the leachate was used in the production of 2024年1月1日 A potential measure to mitigate climate change and high energy consumption is the conversion of the abundant carbon dioxide (CO2) in industrial flue gas into valueadded products Herein, combined with the 300,000 tonnes of electrolytic manganese metal technical renovation project of Tianyuan Manganese Industry in Ningxia, the methanol production Utilising CO2 from manganese plant flue gas for methanol production 2013年11月21日 The company also plans to start up a 50,000 mt/year electrolytic manganese metal plant next to the mine at the same time Once it obtains operating rights from the Ukraine government, trial production of manganese ore is expected by February 2014, with the full mining operation starting by first quarter 2015, Platts has reported previouslyChina's major electrolytic manganese metal producers plan to 2019年12月11日 Ammonium sulfate double salt crystals (ASDSCs) are a byproduct formed during the electrolytic production of manganese The longterm openair stacking of ASDSCs leads to the manganese and ammonia nitrogen present inside leaching with rainwater, which seriously damages the ecological environment To find a reasonable treatment method, we PretreatmentMembrane Electrolysis Process for Treatment of

Production of Manganese in China, 2020 2028 (Million Tonnes)

Production of Manganese in China reached 677Million Tonnes in 2023 Global manganese mining industry The main companies operating in the global manganese mining industry are CITIC Dameng Holdings Ltd, MOIL Ltd, African Rainbow Minerals Ltd, Anglo American, Tata Steel Ltd, and Rungta Mines Ltd Global manganese reserves held a significant position, with 2024年11月15日 HPMSM Processing 101 Process Routes for High Purity Manganese Production Most of the world’s commercial production of high purity manganese is based in China and this summary contains information from operating Chinese production plantsHPMSM Processing 101 Canadian Manganese2021年11月20日 Electrolytic manganese residue (EMR) is a solid waste with a main mineralogical composition of gypsum It is generated in the production of metal manganese by the electrolysis process In this research, EMR, fly ash, and clinker were blended to make fly ashbased cementitious material (FAC) to investigate the effect of EMR on strength properties, Effect of Electrolytic Manganese Residue in Fly AshBased2016年5月1日 Sulfur dioxide was first used to produce electrolytic manganese commercially with a reasonable current efficiency (60–65%) The effects of SO 2 are: (1) increasing the overpotential of hydrogen evolution and hence the manganese current efficiency; (2) promoting the formation of stable αmanganese, (3) counteracting the harmful effects of impurities, and (4) suppressing Electrolytic manganese metal production from manganese

How to Start Electrolytic Manganese Dioxide (EMD) Production

Use detailed tutorial to learn the stepbystep procedure for starting the manufacturing of electrolytic manganese dioxide (EMD Our experienced professionals will conduct extensive research to gather accurate data and conduct indepth analyses to Analysis of the economics of the plant, including production schedules and 2019年5月23日 The smelting of manganese ores is mainly performed through electrolysis and reduction to produce pure manganese Electrolysis produces over 95% of total manganese metal products [], and electrolytic manganese (EM) has very high purity and used mainly as deoxidant and desulfurizing agent in iron and steel smelting processesManganese is the element most Resource Utilization of Electrolytic Manganese ResiduesPlant Layout: Details on the plant layout and utility requirements Project at a Glance Our reports provide a snapshot of the project, including: Assumptions for Profitability Workings: Assumptions used in profitability calculations Plant Economics: Analysis of the plant's economics Production Schedule: Detailed production schedulesElectrolytic Manganese Dioxide (EMD) Industry in India: A It is the starting material for electrolytic manganese metal, electrolytic manganese dioxide, This dataset represents the production of manganese sulfate from manganese concentrate The inventory is based on stoichiometric calculations and approximations based on data from a large chemical plant (Gendorf 2016) References: Reidies, A H 2000manganese sulfate production, UPR, ecoinvent 36, Allocation,

.jpg)

Technoeconomicenvironmental analysis based on life cycle

2024年11月1日 This enterprise has a comprehensive EMM production chain encompassing power plants, manganese mines, electrolytic manganese plants, and is the sole industrialscale production line for utilising manganese residue resources worldwide Over the years, the company has contributed approximately 40 % of EMM production worldwide1990年1月1日 The National Metallurgical Laboratory, Jamshedpur, India has established a 50kg/day electrolytic manganese dioxide and 50 kg/day electrolytic manganese metal pilot plant Various manganese ores from different parts of India and abroad have been tested in the pilot plant, using various equipment and materials of constructionPILOT PLANT STUDIES FOR THE PRODUCTION OF ELECTROLYTIC MANGANESE 2006年11月1日 The use of ferroalloy fines, especially the (FeMn) alloy, to replace Rhodocrosite in the production of electrolytic manganese was studied This approach helped to solve the environmental problem Reuse of furnace fines of ferro alloy in the electrolytic manganese Manganese ore used in the production process comes from the Northern Cape Province of South Africa, which is known to contain 75% of the world’s identified manganese ore reserves Plant capacity: The company was established in 2007 when the Renova Group, a Russian diversified investment holding, acquired the plantTransalloys, South Africa International Manganese Institute

Electrolytic Manganese Manganese Dioxide from Lowgrade

that 30`), manganese, the cost of production of electrolytic manganese in India in a 10tonaday plant is not likely to exceed Rs 1,00(1 a ton The work being done at the Laboratory to produce electrolyticbatteryactive manganese dioxide front lowgrade Indian ores, is discussed separately; it is stated that labo