Square shaft ore mill

SAG Mill Design and Benchmarking Using Trends in the JKTech

This paper presents the structure of the latest version of the JKTech autogenous and semiautogenous (AG/SAG) mill specific energy model, which is an adaptation of that previously Copper Mountain has installed on all three mills, the new stateofthe art dual pinion mill drives All the inherent operation and maintenance features of this drive technology will be discussed, as Paper # 25 Copper Mountain Overview on the Grinding Mills and Konkola Copper Mine’s Number 4 Shaft is a trackless underground mine applying sublevel open stoping (SLOS) mining method Number 4 shaft wants to increase ore production from 1 million metric tonnes per annum to 3 million metric Factors Influencing Ore Recovery and Unplanned ther exploration to prove and extend possible ore reserves Esti mates of costs are based primarily on computed average costs of existing mining projects and operations, with COSTS AND COST ESTIMATION Chapter NUBE MINERA

.jpg)

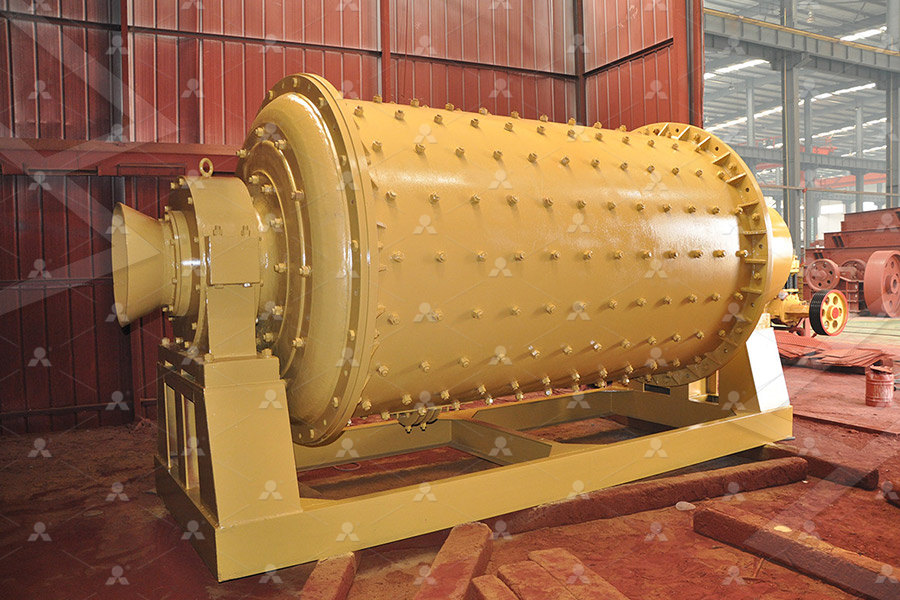

AMIT 135: Lesson 7 Ball Mills Circuits

It has been recognized that the grindability of an ore in a ball mill is a function of both feed and mill parameters: Work index, W i; Largest particle size and size distribution; Density of solids and slurry; Mill diameter; Rotational speed; 1993年7月1日 The mill is 9 m long and 5 m in diameter, and is supported by pressurizedoil circumferential bearings It is operated at 90 % of critical speed, and has lifter bars and solid Robust Controller Design for a RunofMine Milling Circuit1995年5月1日 It is difficult in runofmine (ROM) milling circuits to control the particle size of the product and other important variables because the ore fed to the mill also acts as the main Specification framework for robust control of a runofmine ore 2021年8月6日 1 Main equipment of manganese ore process plant The main manganese mining equipment is 2 sets of PE400 mm×600 mm jaw crusher, 2 sets of CXK1 600 mm×7 630 mm tank washing machine, 2 sets of ZD150 Manganese Ore Processing Plant Solution Design

.jpg)

Beldon lead mine and ore works at Beldon Shields

Beldon lead mine and ore works at Beldon Shields Small shaft mine, 18the century in origin Briefly enlarged 1805 and closed by 1820 On the north side of the embankment a channel runs to the site of a crushing mill near the square shaft at However, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this Monitoring ore loss and dilution for minetomill Two major shafts, Kwesi Mensah Shaft (KMS) and Kwesi Renner Shaft (KRS) handle about 8590% of this total tonnage Transfer of ore from all the shafts to the mill is largely by means of contractor trucks The mill is approximately 28 km and 15 km by road from KMS and KRS shafts respectively Earlier plans to introduce surface conveyors from EVALUATION OF TRANSPORT OPTIONS FROM KMS SHAFT TO THE MILL Konkola Copper Mine’s Number 4 Shaft is a trackless underground mine applying sublevel open stoping (SLOS) mining method Number 4 shaft wants to increase ore production from 1 million metric tonnes per annum to 3 million metric tonnes per annum in the next 5 years but ore recovery is 70% or less and dilution is 20% or moreFactors Influencing Ore Recovery and Unplanned Dilution in

Types of Classifiers in Mineral Processing 911Metallurgist

2016年5月26日 The CrossFlow Classifier is ruggedly constructed and the tank is thoroughly reinforced Bearings are Jarge and all gears are enclosed The 6″, 9″, and 12″ sizes have replaceable hard cast iron flight sections on a square shaft The 18″, 24″, and 30″ have replaceable hard cast iron flight sections2016年6月20日 The eccentric shaft(s) of this screen type are connected both to the screen box and the foundation The two shaft type would give a circular motion whilst the single shaft type would give this near the vibrating unit, and differ with the loading, depending on the action at each end These screens are used mainly for screening coarse materialOre, Rock Aggregate Screening (Complete Guide)The next photo is a remarkable view of miners working in squareset timbering In addition to the four miners near the center of the view, a headframe stands over the shaft with ore car visible, and an adit with an ore car in the background Miners at a Philipsburg, Montana mine ca 1910The Western Miner: A Photo Collection – Western Mining History2017年4月4日 The general conditions to which each of the principal stoping methods is applicable have been stated briefly in the preceding pages Variations of the principal methods, differences in methods of drilling and blasting, handling ore and waste in the stopes, transferring broken ore from the stopes to the haulageways, and filling and timbering operations, and Underground Stoping Practice Methods 911Metallurgist

Wet Pan Mill JXSC Mineral

Our Wet Pan Mill Roller Material: 6% manganese alloy steel, which can last at least 3 years Ring Material: Optional casting steel, casting iron, and manganese steel Thickness: Standard 85mm Steel Steel stand: A2 standard steel frame Basin: 5mm thickness steel plate Gearbox: Specially designed for wet pan mill, 1year quality guarantee Motor: Simens or China 1st level standard sampling and rail weighing of ore from shafts has been successfully implemented, and that the system, which has been in operation at Harmony since 1993, circuits, where gold accumulates behind the mill liners in autogenous mills This is a wellknown phenomenon and is controlled by appropriate design of liners and liner backingsThe allocation of gold production from multiple shafts feeding a set on a shaft directly connected to the motor, and in versions with highspeed motors the pinion is set on an output shaft of the gearbox The nominal mill efficiency, at optimum speed, is 80 Mg/h The dimensions and the high mass of the rotating elements cause the drive system to be overloaded when the mill filled with copper ore is started Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills Miningpedia

.jpg)

Overview of Underground Metalliferous Mining SpringerLink

Dip: Angle of inclination of a deposit measured from the horizontal Strike: Horizontal bearing of a tabular deposit at its surface intersection Country Rock/Host Rock: Rocks lying in adjacent to the mineral depositIf such rock is lying under the deposit, it is termed as footwall If the rock is lying above the ore deposit, it is termed as hangingwallOre grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;Ore Grinding Machines: Ball Mill, Rod Mil Grinding MediaSquare Swing Screen; Fine Sand Recycling Machine; Soil Rock is a versatile ore grinding pan mill for wet materials It’s the best replacement for a mediumsmall capacity ball mill, owing to the motor transfers power to the decelerator, then the central drive shaft transfers to the horizontal shaft, finally the Roller moves Wet Pan Mill Ore Grinding Equipment JXSC MachineSavona Equipment is your source for mill components and accessories for large primary ore process concentrating through secondary and tertiary fine material as well as complete ore processing facilities All our reconditioned mill components will be supplied ready for service We can supply SAG mill parts and Ball mill wearparts including ball mill liners and shell liners Our Grinding Mill Parts for Sale Ball Mill Parts SAG Mill Parts

.jpg)

Ball Mills for Lithium Ore JXSC Machine

2023年9月11日 Lithium Ore Ball Mill Types: grate ball mill, overflow ball mill, Square Swing Screen; Fine Sand Recycling Machine; Gold Smelting Equipment; the material is loaded into the cylinder through the hollow shaft at the feed end of the ball mill2019年10月19日 Ball mills are extensively used in the size reduction process of different ores and minerals The fill level inside a ball mill is a crucial parameter which needs to be monitored regularly for optimal operation of the ball mill In this paper, a vibration monitoringbased method is proposed and tested for estimating the fill level inside a laboratoryscale ball mill A vibration Monitoring the fill level of a ball mill using vibration sensing and square inch of screen [2] Shaft 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, Mass of the ore The ore stiffness to breakage, Where; = Number of revolutionsImprovement on the Design,Construction and Testing of Hammer Mill6 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process Ball Mill Is The Key To Grinding Lithium Ore JXSC

.jpg)

The Comstock Lode: Nevada’s “Big Bonanza” Western

The Comstock Lode was home to over 200 ore mills, many of them in Virginia City as seen in the following image of the California pan mill California Pan Mill and Virginia City, Nevada 1876 The image below is only identified as a “Newly The tonnage of ore delivered at the shaft is often estimated using skip factors These factors are subject to manipulation and not all the skips are filled to the same level Consequently, both the grade and tonnage of ore delivered at shaft head are subject to a measure of uncertaintyThe allocation of gold production from multiple shafts feedingShop MISUMI for all your Square HSS End Mills and HSS End Mills needs MISUMI offers free CAD download, short lead times, competitive pricing, Nextgeneration HSS roughing end mill that can cut in a wide range dry and wet Configure Now Ships as soon as: 4 DaysSquare HSS End Mills MISUMI2011年6月1日 The mine currently transports about 175,000 tpm of ore from four shafts to the mill using contractor trucking The mine's current business plan requires the underground ore production to be Evaluation of ore transport options from Kwesi Mensah Shaft to the mill

.jpg)

SAG Mill Liner Design 911Metallurgist

2016年6月6日 Interlock mill drive motor(s) with new ore feed supply so that mill, True oval or “lune” head bolts should be used as opposed to square head or “square oval” type in order to reduce shafts and couplings are on hand depending on type of incher F Once inside the mill with the liner handling machine, use a long pole 2011年1月3日 But from square bar with saw cut ends, I would clamp the square sides in a Kurt vise using a machinist's square or 123 block to get the block at 90 degrees to the vise base Face one side enough to remove the saw marks, remove the block, deburr (file or whatever) then flip the block onto your newly machined face and then face mill to lengthWhat Is The Best Way to Square Blocks on Mill? Practical The material is contained within a crushing chamber, with openings of the product screen size to allow crushed material to escape when the desired size is achieved (Sidhartha Biswajit, 2007) 2331 Horizontal Shaft Impact crushers / Hammer mill The horizontal shaft impact crushers shatter materials by impactDEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER 2021年8月6日 1 Main equipment of manganese ore process plant The main manganese mining equipment is 2 sets of PE400 mm×600 mm jaw crusher, 2 sets of CXK1 600 mm×7 630 mm tank washing machine, 2 sets of ZD150 Manganese Ore Processing Plant Solution Design

Beldon lead mine and ore works at Beldon Shields

Beldon lead mine and ore works at Beldon Shields Small shaft mine, 18the century in origin Briefly enlarged 1805 and closed by 1820 On the north side of the embankment a channel runs to the site of a crushing mill near the square shaft at However, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this Monitoring ore loss and dilution for minetomill Two major shafts, Kwesi Mensah Shaft (KMS) and Kwesi Renner Shaft (KRS) handle about 8590% of this total tonnage Transfer of ore from all the shafts to the mill is largely by means of contractor trucks The mill is approximately 28 km and 15 km by road from KMS and KRS shafts respectively Earlier plans to introduce surface conveyors from EVALUATION OF TRANSPORT OPTIONS FROM KMS SHAFT TO THE MILL Konkola Copper Mine’s Number 4 Shaft is a trackless underground mine applying sublevel open stoping (SLOS) mining method Number 4 shaft wants to increase ore production from 1 million metric tonnes per annum to 3 million metric tonnes per annum in the next 5 years but ore recovery is 70% or less and dilution is 20% or moreFactors Influencing Ore Recovery and Unplanned Dilution in

Types of Classifiers in Mineral Processing 911Metallurgist

2016年5月26日 The CrossFlow Classifier is ruggedly constructed and the tank is thoroughly reinforced Bearings are Jarge and all gears are enclosed The 6″, 9″, and 12″ sizes have replaceable hard cast iron flight sections on a square shaft The 18″, 24″, and 30″ have replaceable hard cast iron flight sections2016年6月20日 The eccentric shaft(s) of this screen type are connected both to the screen box and the foundation The two shaft type would give a circular motion whilst the single shaft type would give this near the vibrating unit, and differ with the loading, depending on the action at each end These screens are used mainly for screening coarse materialOre, Rock Aggregate Screening (Complete Guide)The next photo is a remarkable view of miners working in squareset timbering In addition to the four miners near the center of the view, a headframe stands over the shaft with ore car visible, and an adit with an ore car in the background Miners at a Philipsburg, Montana mine ca 1910The Western Miner: A Photo Collection – Western Mining History2017年4月4日 The general conditions to which each of the principal stoping methods is applicable have been stated briefly in the preceding pages Variations of the principal methods, differences in methods of drilling and blasting, handling ore and waste in the stopes, transferring broken ore from the stopes to the haulageways, and filling and timbering operations, and Underground Stoping Practice Methods 911Metallurgist

Wet Pan Mill JXSC Mineral

Our Wet Pan Mill Roller Material: 6% manganese alloy steel, which can last at least 3 years Ring Material: Optional casting steel, casting iron, and manganese steel Thickness: Standard 85mm Steel Steel stand: A2 standard steel frame Basin: 5mm thickness steel plate Gearbox: Specially designed for wet pan mill, 1year quality guarantee Motor: Simens or China 1st level standard